Unlock insights, predict challenges and resolve issues with an equipment 360-view

In the first part of our series, we discussed how equipment management has lagged behind the advances seen in customer relationship management (CRM), where a unified view of data has greatly enhanced customer interactions. Equipment management, by contrast, has suffered from fragmented and siloed data, making it challenging to obtain a holistic understanding of equipment performance and maintenance needs.

This part will explore how AI can integrate these disparate data sources, offering a unified view similar to CRM systems, thus enhancing the management and efficiency of equipment.

Create a unified view with Equipment 360

At the heart of Equipment 360 lies robust generative AI, which is tailored specifically to the nuances of equipment management. This specialized Equipment AI effectively connects the dots between various disparate data streams—such as parts inventories, maintenance records, and operational data—to create a comprehensive, 360-degree view of your equipment’s status and needs. By intelligently integrating this information, Equipment 360 not only identifies potential design issues before they affect performance but also predicts how to resolve complex service and support issues faster. These capabilities allow your business to anticipate challenges and seamlessly adapt operations, greatly improving operational performance and agility.

See clearly, act decisively

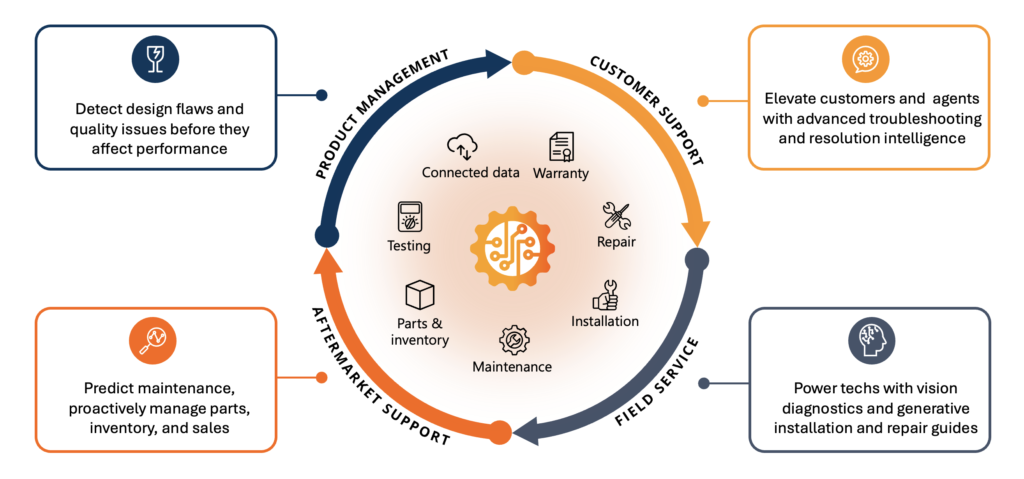

The ability to create an Equipment 360 view delivers a unified, transparent view that cuts through complexity. This comprehensive visibility is crucial, enabling service heads and IT professionals to fully understand their operations and make informed, data-driven decisions with the predictive intelligence inherent in AI. By analyzing usage patterns and predicting potential failures, Equipment 360 empowers your teams across product management, customer service, field service, and product aftermarket to proactively address issues before they disrupt operations.

Comprehensive solutions across the equipment lifecycle

Equipment 360 delivers tailored solutions that span all phases of the equipment lifecycle, enhancing reliability, customer satisfaction, and operational efficiency:

- Product management: Equipment 360 solutions provide a robust ‘twinned view’ of each piece of equipment, harnessing the power of digital twins and AI analytics. AI’s inherent predictive capabilities analyze service and warranty data for the timely detection of quality or design issues. Using ‘service twins’ product managers can visualize their products using real-world feedback, to mitigate unforeseen issues with installed equipment and develop future products that are more reliable and efficient, thereby enhancing customer satisfaction and extending product lifecycle. This proactive approach helps ensure that the equipment runs reliably from the start, minimizing disruptions and optimizing performance over time.

- Customer support: Customer support agents can access essential information, enabling even non-technical staff and new agents to effectively triage equipment issues. Equipment 360 solutions centralize detailed equipment histories, maintenance records, and user documentation, allowing agents to find and utilize data quickly. Integrated guided decision paths and diagnostic tools help agents understand and assess problems for swift resolutions. This reduces wait times as well as overall support costs and increases customer satisfaction.

- Field service: Equipment 360 enhances field service operations by equipping technicians with an integrated suite of tools designed to drive efficiency and precision. From the outset, technicians benefit from self-guided, personalized installation guides that ensure proper setup and testing, and enable even new technicians to complete complex jobs. The tools provide prescriptive decision paths and easy access to relevant manuals, specs, and videos for ongoing maintenance and troubleshooting. Advanced image recognition and diagnostics capabilities help to identify problems and necessary parts, which can be ordered directly through the system.

- Aftermarket support: Using comprehensive equipment issue analysis and parts performance data Equipment 360 solutions predict repair needs for specific equipment issues, ensuring on-time orders and reduced returns. Equipment AI streamlines the repair process through direct part ordering and availability on service trucks. By analyzing the 360-degree view of comprehensive parts and service data, you can optimize inventory levels, align them with demand and minimize overheads. This strategic view helps transform equipment management from a traditionally reactive task to a strategic, proactive advantage, reducing downtime and optimizing performance.

Equipment AI for secure and rapid Integration

Equipment 360’s specialized AI is designed for seamless integration with your existing IT infrastructure, focusing on enhanced security and rapid deployment. It operates securely within your organizational firewall, ensuring that sensitive data stays within the organization. The AI is designed from the ground up to be deployed within 5-7 weeks, allowing your team to focus more on leveraging insights instead of managing data logistics. It is embedded directly into your environment, giving you full control and ownership of all intellectual property.

Conclusion

The current fragmented data landscape poses significant challenges to comprehensive equipment management. Essential information such as equipment health, usage history, maintenance schedules, and troubleshooting procedures is often inaccessible to those directly involved in managing and supporting equipment. This adversely impacts all service delivery areas, including product management, customer support, field service operations and aftermarket sales.

A 360-degree view of the equipment gives organizations a clear and unified perspective of all operational facets. This integrated approach improves the operational experience and enhances overall efficiency, leading to improved outcomes across the board.

Discover the power of an Equipment 360 view for your business—get a live demo today.