Custom asset tracking integration drains budgets and engineering time when pre-built APIs deliver faster with zero vendor lock-in.

Semiconductor OEMs reduce integration costs 60-70% by using pre-built asset tracking APIs instead of building from scratch. Standardized endpoints eliminate custom ERP connectors, reduce maintenance burden by 40%, and enable configuration drift detection without dedicated data engineering teams.

Building asset tracking integrations from scratch requires dedicated backend engineers to map ERP schemas, handle authentication, write transformation logic, and maintain API versioning. Each new fab system adds weeks of development time.

Custom integrations break when SAP or Oracle releases updates. Configuration drift detection requires constant schema mapping adjustments. Your team spends more time fixing connectors than building product features.

Detecting incomplete asset records or configuration drift requires building custom data quality pipelines. Your engineers write one-off Python scripts instead of leveraging standardized anomaly detection endpoints.

Pre-built APIs eliminate the need to build asset tracking infrastructure from scratch. Standardized REST endpoints connect to SAP, Oracle, and custom data lakes without custom connectors. Python and TypeScript SDKs provide typed interfaces for asset registry queries, configuration comparison, and lifecycle event tracking.

The platform handles schema mapping, authentication, and API versioning automatically. Configuration drift detection runs server-side via standardized telemetry ingestion endpoints. Your team writes business logic against stable interfaces instead of maintaining brittle ERP integrations. When Oracle updates its schema, the API adapter layer absorbs the change without breaking your code.

API-driven telemetry ingestion identifies lithography tool anomalies by comparing real-time sensor streams against expected configuration baselines, eliminating custom integration code.

Standardized endpoints monitor etch chamber performance deviations without building custom data pipelines, reducing time-to-detection from weeks to minutes.

Pre-built lifecycle APIs forecast chamber kit replacement timing using FOUP cycle counts and recipe drift patterns, eliminating months of custom model development.

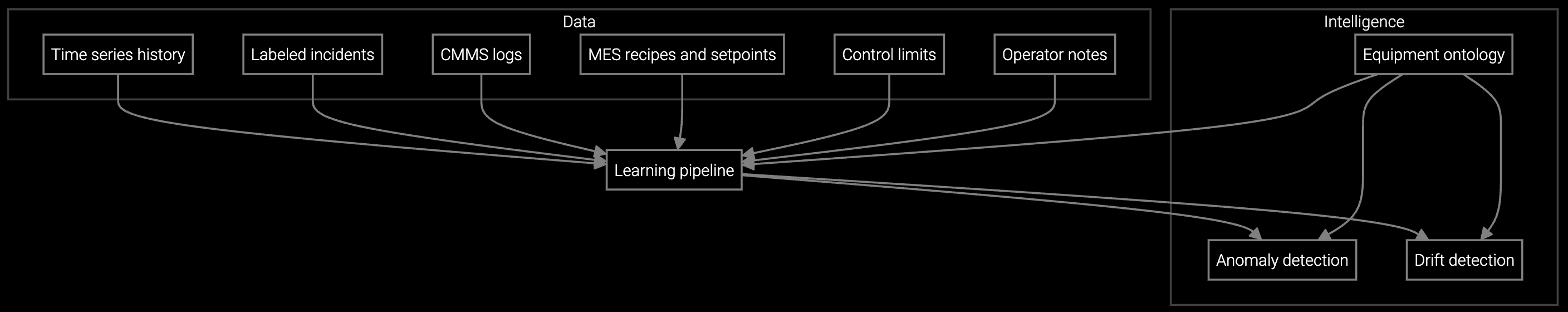

Semiconductor OEMs manage thousands of high-value lithography, etch, and deposition tools across multiple fabs. Each tool generates telemetry streams tracking chamber hours, recipe parameters, and consumable usage. Traditional approaches require custom Python scripts to parse SECS/GEM data feeds, map tool IDs to ERP asset records, and detect when installed configurations drift from engineering baselines.

Pre-built APIs eliminate this development overhead. Standardized telemetry ingestion endpoints accept FOUP cycle counts, process recipe versions, and chamber component serial numbers. Configuration comparison endpoints identify when a tool's installed software version differs from the golden image without writing custom diff logic. The platform's asset registry API maintains the relationship between tool serial numbers, installed software versions, and PM schedules, accessible via typed SDK methods.

Custom connector development (12-18 weeks per ERP system), schema mapping logic for SAP and Oracle, authentication handling, API versioning maintenance, and data transformation pipelines. Pre-built endpoints provide standardized interfaces that absorb backend complexity, letting your team write business logic instead of integration plumbing.

APIs follow REST standards with typed Python and TypeScript SDKs. Your code calls standard HTTP endpoints, not proprietary protocols. Asset data exports via JSON, and you can migrate to alternative providers by swapping API base URLs. The platform provides integration adapters, not a closed ecosystem.

You maintain business logic and API consumer code. The platform handles ERP schema updates, authentication token refresh, rate limiting, and endpoint versioning. When Oracle changes field names, the adapter layer absorbs the change without breaking your code. Maintenance drops from 40% of engineering time to routine dependency updates.

Compare 12-18 weeks of custom connector development plus 6-8 months building data quality pipelines against 2-4 weeks integrating pre-built API endpoints. Include ongoing maintenance costs: custom code requires 40% of engineering time on fixes, while standardized APIs need only routine SDK updates.

Yes. APIs provide webhooks for lifecycle events and support custom metadata fields on asset records. You can layer proprietary business logic atop standardized endpoints without forking the codebase. Python SDKs expose extension points for custom transformations while maintaining compatibility with core platform updates.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Review endpoint specifications, SDK examples, and integration architecture to validate cost reduction claims.

Talk to an Expert