Equipment with 20-year lifecycles demands service infrastructure that pays back over time, not just this quarter.

AI customer service integration reduces costs through faster case resolution, lower contact volume, and reduced escalations. Typical industrial OEMs see 25-35% lower cost per contact within 12 months through automated triage, knowledge retrieval, and consistent agent guidance.

Agents search across manuals, parts catalogs, and legacy systems to answer equipment-specific questions. Complex machinery with decade-old models means documentation is fragmented and tribal knowledge is siloed.

Agents lack context to resolve issues on first contact, leading to callbacks, escalations, and customer frustration. Each repeat contact adds cost without adding value.

New agents take months to ramp up on equipment nuances. Senior agents carry institutional knowledge but cannot scale. Performance variance drives unpredictable service costs.

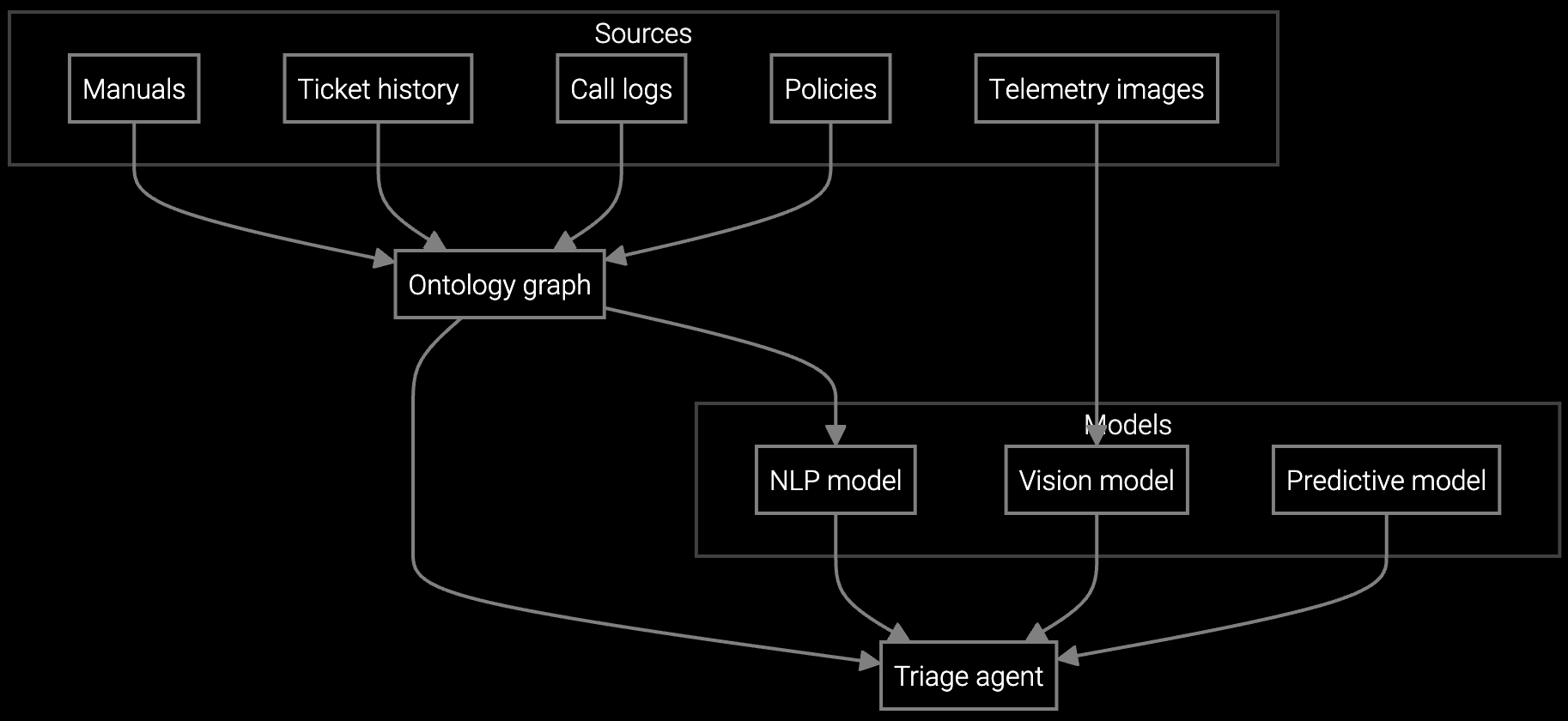

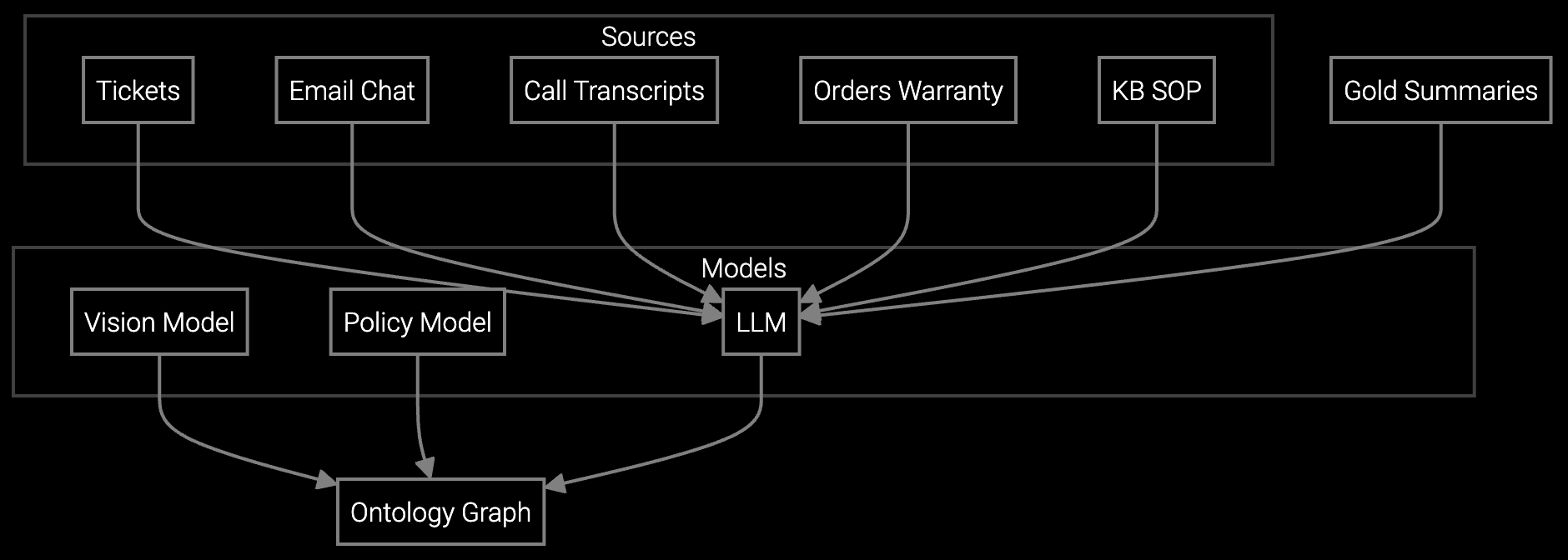

Bruviti's API-first platform integrates with existing CRM and ticketing systems without requiring data migration or workflow overhaul. Python and TypeScript SDKs allow developers to customize case routing logic, knowledge retrieval, and agent copilot behavior using standard languages. The platform ingests historical case data, equipment manuals, and sensor telemetry to train domain-specific models that understand your equipment and service processes.

The architecture avoids vendor lock-in by exposing all functionality through REST APIs. Custom models can be trained on your data lake using open frameworks, then deployed through the platform's inference engine. Integration costs are predictable because developers control the scope and pace of rollout across product lines and geographies.

Autonomous case classification for heavy machinery correlates symptoms with equipment telemetry and routes issues with diagnostic context, reducing triage time from 8 minutes to under 2.

Instant case summaries from multi-channel history let agents understand equipment context and past interactions without reading through years of service records.

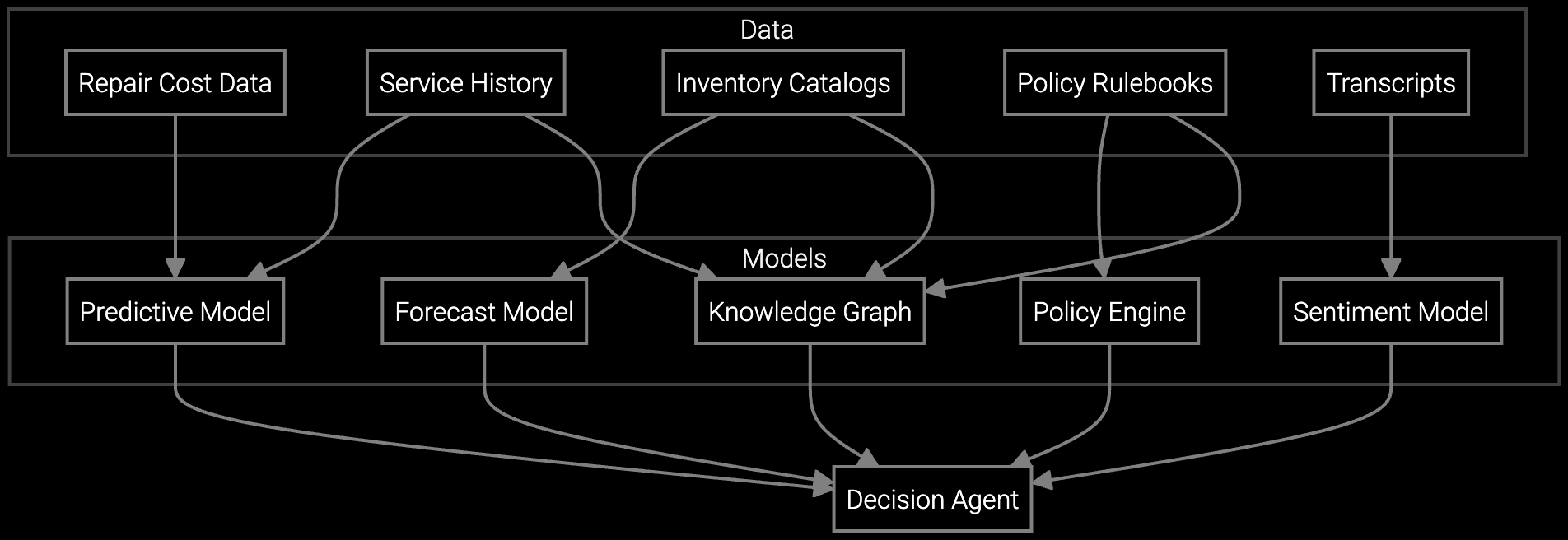

AI analyzes failure modes, part costs, and equipment age to recommend the most cost-effective resolution path for industrial equipment approaching end-of-life.

Industrial OEMs support equipment for 10-30 years, making service infrastructure a multi-decade investment. Cost per contact is the primary driver of service P&L because contact volume grows as installed base ages. Average handle time directly impacts agent headcount requirements, which represent 60-70% of service center operating costs.

The ROI calculation for AI integration hinges on three levers: reducing AHT by surfacing the right knowledge faster, improving FCR by equipping agents with better diagnostic context, and shortening ramp time by codifying expert responses. Each 10% reduction in AHT yields $1M-$1.5M in annual savings per 100 agents at typical industrial service volumes.

Most industrial OEMs see payback in 12-18 months through reduced AHT and improved FCR. The timeline depends on baseline agent performance, integration complexity, and rollout scope. OEMs starting with clean data and modern CRM systems typically hit ROI faster than those with legacy ERP integrations.

Track First Contact Resolution rate, Agent Ramp Time, Customer Satisfaction scores, and Escalation Rate. These metrics predict long-term service margin and customer retention. Improved FCR reduces not just immediate costs but also downstream warranty claims and field service dispatches.

Plan for 3-6 months of developer time to integrate with CRM, train initial models on historical data, and customize agent workflows. Most projects require 2-3 full-time engineers plus part-time involvement from service operations and data teams. Cloud infrastructure costs run $5K-$15K per month depending on case volume.

Yes. Bruviti's API-first architecture allows you to train models using open frameworks on your own infrastructure, then deploy them through the platform's inference engine. This avoids data egress costs and maintains control over sensitive equipment data and intellectual property.

Typical first-year savings range from $1.5M-$3M for every 100 agents through AHT reduction, FCR improvement, and faster agent ramp. OEMs with high case complexity and long equipment lifecycles see stronger returns because the knowledge retrieval and diagnostic guidance capabilities deliver outsized value on technical cases.

Understanding and optimizing the issue resolution curve.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Review API documentation, SDK examples, and integration patterns with Bruviti engineers.

Talk to an Engineer