Rising service volumes and agent turnover drive unsustainable cost-per-contact growth across global support operations.

Industrial manufacturers reduce customer service costs 40-55% through AI-driven case routing, automated email triage, and agent knowledge retrieval. Cost savings stem from lower AHT, improved FCR, and reduced training overhead for distributed support teams.

Agents spend 8-12 minutes per case searching disconnected knowledge systems for legacy equipment documentation. Manual lookups across service bulletins, parts catalogs, and archived case histories extend resolution time and limit cases per agent per day.

Only 62-68% of cases close on first contact. Repeat contacts increase labor costs, erode customer satisfaction, and create backlog pressure during equipment commissioning and seasonal maintenance peaks.

New agents require 6-9 months to reach full productivity on complex industrial equipment portfolios. Long ramps delay headcount ROI, increase supervisor burden, and expose quality risks during product line transitions or acquisitions.

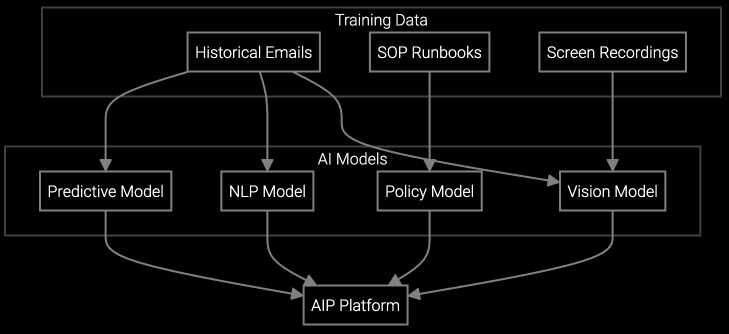

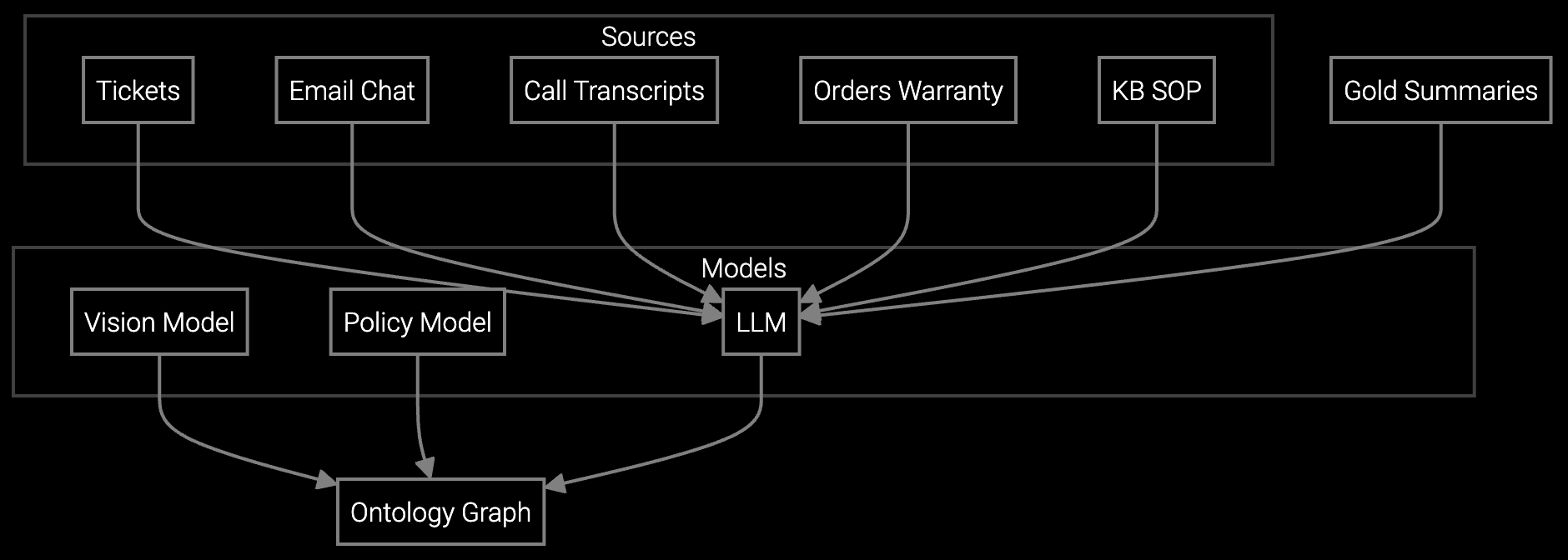

Bruviti delivers cost savings through three compounding mechanisms. First, the platform reduces Average Handle Time by feeding agents instant answers from unified equipment knowledge across decades of service history, technical bulletins, and parts databases. Knowledge retrieval that previously took 8-12 minutes now happens in seconds through conversational queries.

Second, AI-driven case routing and automated email triage eliminate manual classification labor and direct cases to the right specialist on first attempt. This raises First Contact Resolution from 62-68% to 82-88%, cutting repeat contact costs and agent rework. Third, the platform compresses training ramps from 6-9 months to 8-12 weeks by providing new agents with contextual guidance, answer suggestions, and automated case notes—reducing supervisor time and accelerating headcount productivity.

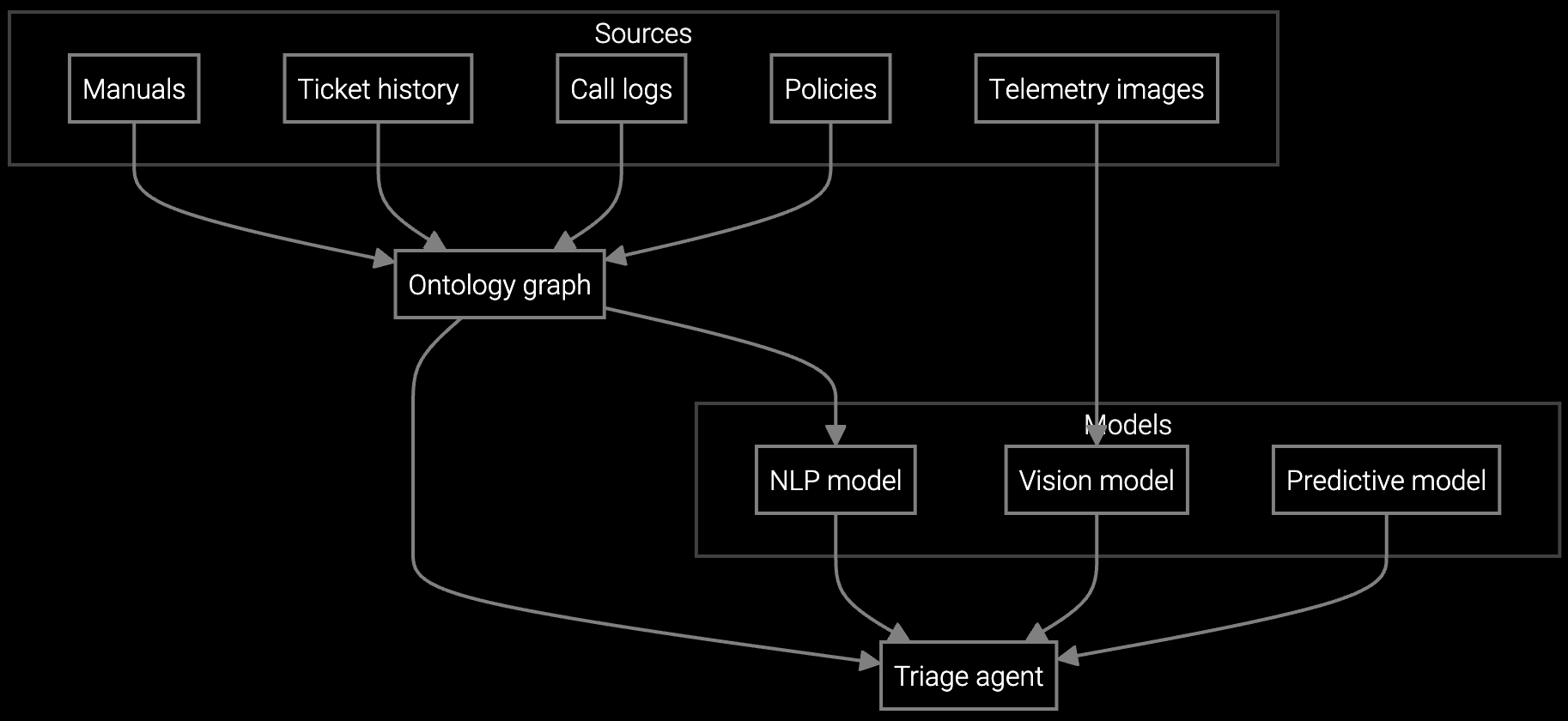

Autonomous AI classifies equipment issues from pump failures to CNC alarms, routing cases to specialized teams with pre-populated diagnostic context from equipment telemetry and service history.

AI reads inbound service requests, extracts equipment serial numbers and failure symptoms, drafts responses using parts availability and maintenance bulletins, and routes cases requiring human review.

Agents receive instant summaries of equipment service history, prior failure modes, installed configurations, and contract entitlements—eliminating manual review before responding to customer inquiries.

Industrial manufacturers support 10-30 year equipment lifecycles across CNC machines, industrial robots, pumps, compressors, and material handling systems. Each product line carries unique parts catalogs, maintenance schedules, and tribal knowledge concentrated in senior agents. Legacy equipment documentation often exists only in PDF service bulletins or retired engineer notebooks.

Contact centers handle diverse inquiries from run hour tracking to PLC programming questions to parts obsolescence. Geographic dispersion compounds complexity—agents in regional hubs must support equipment configurations they've never seen in person. This variability drives high training costs and creates knowledge gaps that extend handle time and depress first contact resolution.

Most industrial manufacturers achieve payback in 5-7 months based on labor cost savings from reduced AHT and improved FCR. Larger portfolios with 10,000+ installed units and distributed support teams see faster returns due to higher baseline contact volumes and training overhead.

Average Handle Time (AHT) and First Contact Resolution (FCR) provide the most direct cost impact. AHT reductions translate immediately to cases per agent per day. FCR improvements cut repeat contact labor and customer frustration. Training ramp time also drives significant cost avoidance but requires 6-12 month measurement windows.

Total annual labor costs (agent salaries, benefits, overhead) divided by total annual contacts yields cost per contact. Industrial manufacturers typically see $45-$85 per contact depending on equipment complexity and agent expertise requirements. Multiply cost per contact by volume to calculate total ROI impact from AHT and FCR improvements.

Accelerators include high case volumes (10,000+ annually), well-documented service history, and strong data integration infrastructure. Delays stem from fragmented knowledge sources, poor data quality in legacy systems, or organizational resistance to changing agent workflows. Clean CRM data and executive sponsorship are critical.

ROI improves as the platform ingests more product line data. Initial deployments on 1-2 product lines establish baseline metrics. Expanding to full equipment portfolios spreads fixed integration costs across larger contact volumes while the platform learns cross-product failure patterns and parts commonalities, further improving answer accuracy and AHT.

Understanding and optimizing the issue resolution curve.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

See the ROI logic for your contact volume, AHT baseline, and equipment portfolio complexity.

Schedule ROI Analysis