Every minute agents spend searching tool manuals costs fab customers uptime—and your service margin.

AI agent assistance typically delivers 18-25% AHT reduction and 12-15 point FCR improvement in semiconductor contact centers by surfacing exact technical answers from equipment manuals, telemetry logs, and process documentation without manual searching.

Agents toggle between ticketing systems, equipment manuals, and telemetry dashboards to answer lithography tool questions. Each lookup extends handle time and delays fab customer resolution.

Different agents provide different answers for the same etch chamber alarm code. Without instant access to verified solutions, repeat contacts spike and fab customers lose confidence.

New agents take 8-12 weeks to learn semiconductor equipment vocabulary and case routing logic. Knowledge gaps during ramp directly impact CSAT and cost per contact.

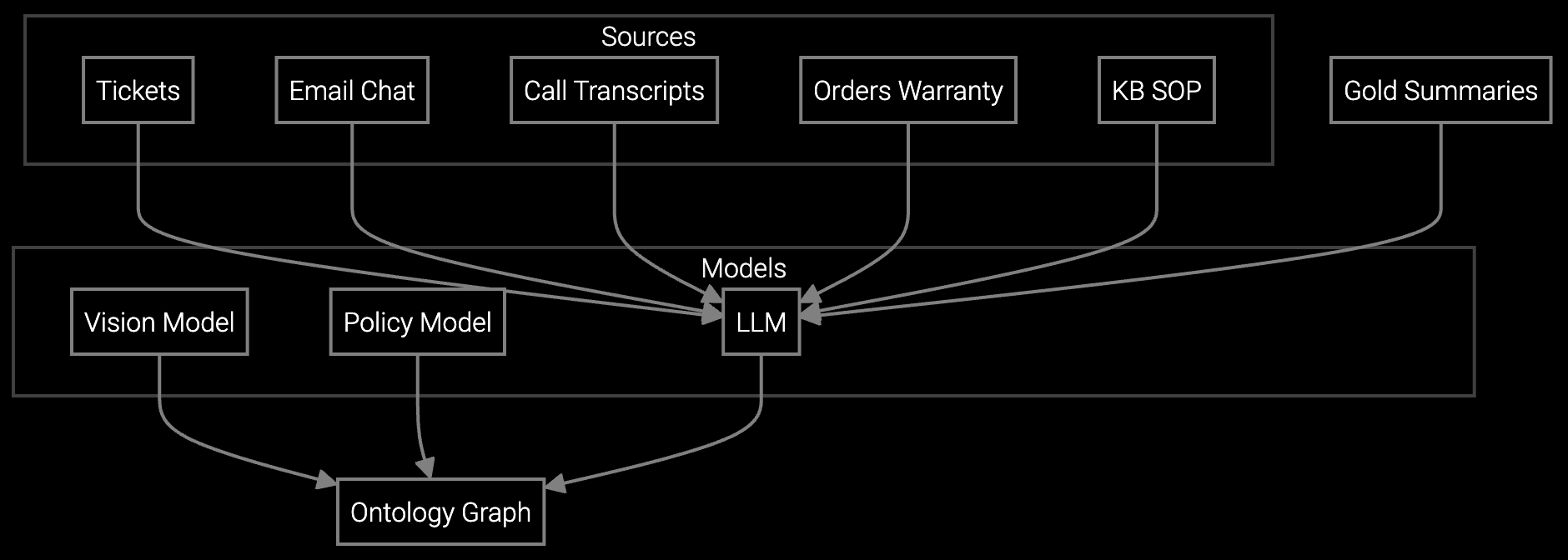

Bruviti's platform eliminates the search step. When a fab customer calls about a deposition tool fault, the copilot instantly surfaces the alarm definition, historical resolution steps from similar cases, and current chamber telemetry—all in a sidebar panel agents read while staying in the ticket.

The agent validates, clicks to populate case notes, and resolves on first contact. Handle time drops because agents stop searching. FCR rises because answers match actual equipment state and proven fixes. Training time shrinks because the AI explains context new agents would otherwise spend months memorizing.

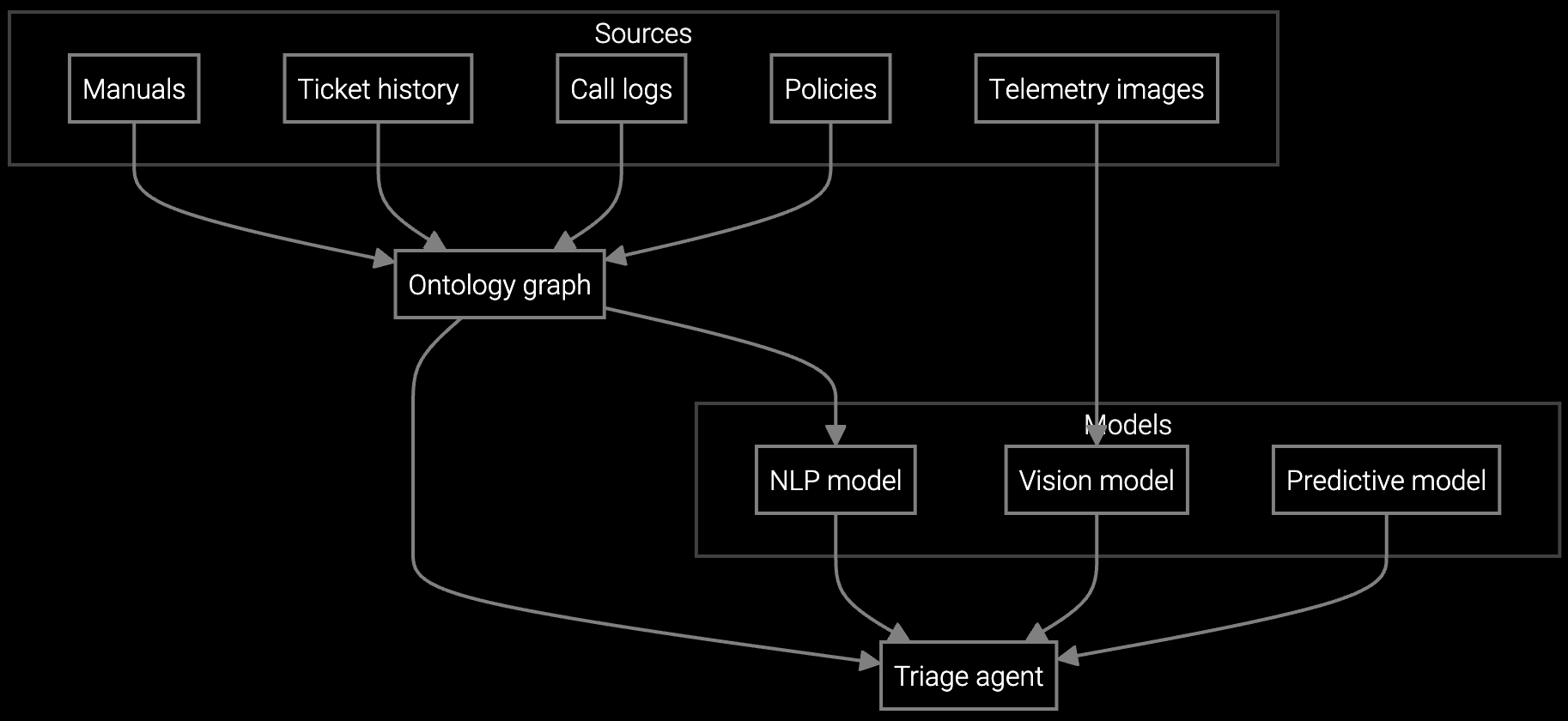

Autonomous classification analyzes lithography tool symptoms, correlates chamber telemetry, and routes cases to EUV or DUV specialists with diagnostic context.

Instantly generates case summaries from fab engineer emails, chat logs, and previous tool service history so agents understand wafer throughput impact.

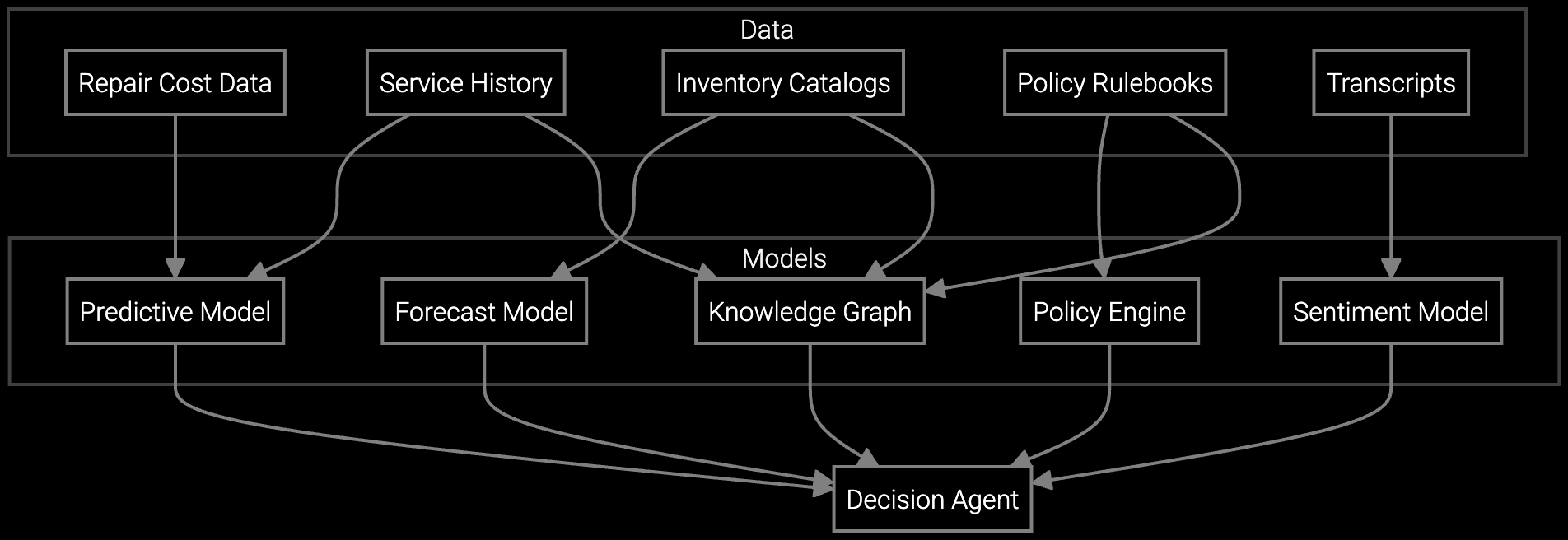

AI analyzes chamber component failure modes, replacement part costs, and tool age to recommend the fastest path to restore fab OEE.

Semiconductor equipment OEMs operate contact centers supporting $150M+ tool install bases. When a fab calls about a metrology system alarm halting wafer inspection, every minute of AHT directly maps to fab downtime cost—often $1M+ per hour. Agents who resolve chamber issues on first contact protect both fab yield and OEM service margin.

The ROI calculation centers on cost per contact reduction and repeat contact avoidance. A 500-seat contact center handling 40K cases monthly at $18 AHT saves $1.44M annually with 20% AHT improvement. Fourteen-point FCR gains eliminate 5,600 repeat contacts yearly, worth $100K in avoided handling costs. New agent ramp acceleration compounds savings as turnover stays high in technical support roles.

Most semiconductor contact centers observe 8-12% AHT reduction within the first 30 days as agents stop opening separate knowledge base tabs. Full 20%+ reduction materializes after 60-90 days once agents trust the copilot sidebar over manual search. Early adopters hit targets faster; laggards need manager coaching to change search habits.

Yes—the platform ingests tool-specific service manuals, process recipes, and historical case resolutions. When a fab engineer describes an EUV source power drift, the copilot surfaces exact recipe parameters, similar past cases with resolution steps, and current telemetry from that specific tool serial number. Agents validate and apply the answer; they don't troubleshoot from scratch.

FCR typically improves 12-15 points when agents have instant access to verified technical answers. Baseline FCR for semiconductor equipment issues often sits at 65-70% due to knowledge fragmentation. AI assistance pushes FCR to 80-85% by surfacing the right fix—matched to tool model, alarm code, and fab operating conditions—on first contact.

Calculate baseline cost per contact by dividing total contact center operating cost by monthly case volume. Then multiply AHT reduction percentage by baseline to find per-case savings. A $720K monthly operating cost with 40K cases equals $18 baseline cost per contact. Twenty percent AHT reduction saves $3.60 per case, or $144K monthly across the center.

Absolutely. New agents typically take 8-12 weeks to learn semiconductor tool terminology, alarm codes, and case routing before they hit productivity targets. AI copilots shorten ramp to 6-8 weeks by explaining context in real time during cases. With 18-22% annual turnover in technical support roles, six-week ramp acceleration saves $4,800 per new hire in reduced training overhead.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

See exactly how much AHT reduction and FCR improvement will save in your semiconductor service operation.

Schedule ROI Analysis