When your queue has 40 open cases and customers expect same-day callbacks, every minute per case compounds into hours of backlog.

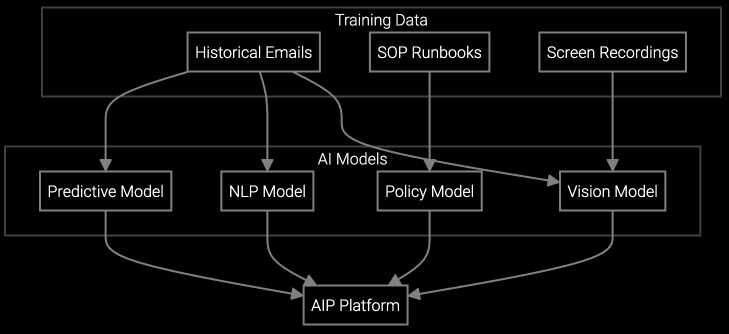

AI reduces average handle time by 35-45% in industrial equipment service centers by automating case classification, parts lookup, and documentation. Agents resolve 8-12 more cases daily with instant access to equipment history and troubleshooting guides.

Agents toggle between CRM, parts database, equipment manuals, and warranty systems to answer one customer question. Each context switch adds friction and delays resolution.

Finding the right troubleshooting procedure for a CNC machine or compressor means searching 200-page PDFs while the customer waits. Agents often escalate rather than dig through documentation.

After resolving the issue, agents spend another 5-8 minutes typing case notes, updating ticket fields, and logging parts ordered. This admin work prevents them from taking the next call.

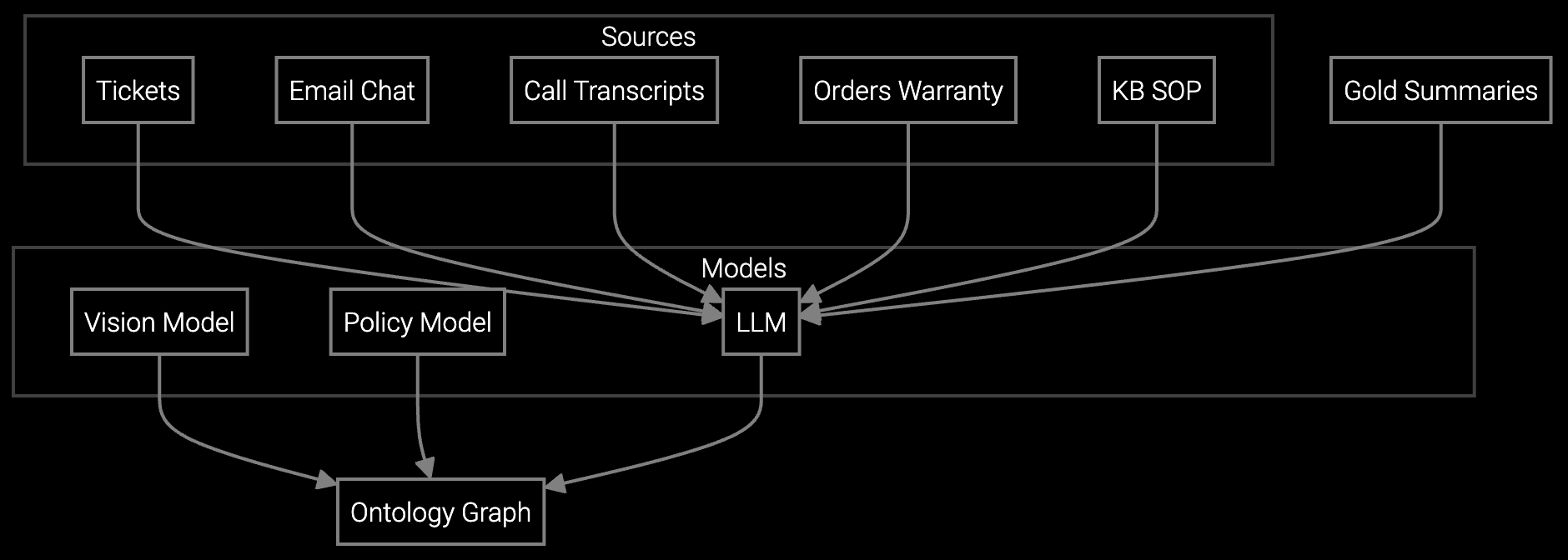

The platform embeds into your existing service workflow as a copilot sidebar. When an agent opens a case about a hydraulic pump failure, the AI instantly retrieves equipment history, common failure modes for that pump model, parts availability, and warranty status—all in one view. No more tabbing between systems or searching through manuals.

Case classification and routing happen automatically. Incoming emails and chat messages get tagged with equipment type, failure symptom, and urgency level before the agent even sees them. Post-call documentation writes itself: the AI drafts case notes from the conversation transcript, suggests next steps, and populates ticket fields. Agents review and click submit instead of typing from scratch. The result: 35-45% reduction in average handle time, which means 8-12 more cases resolved per agent per day.

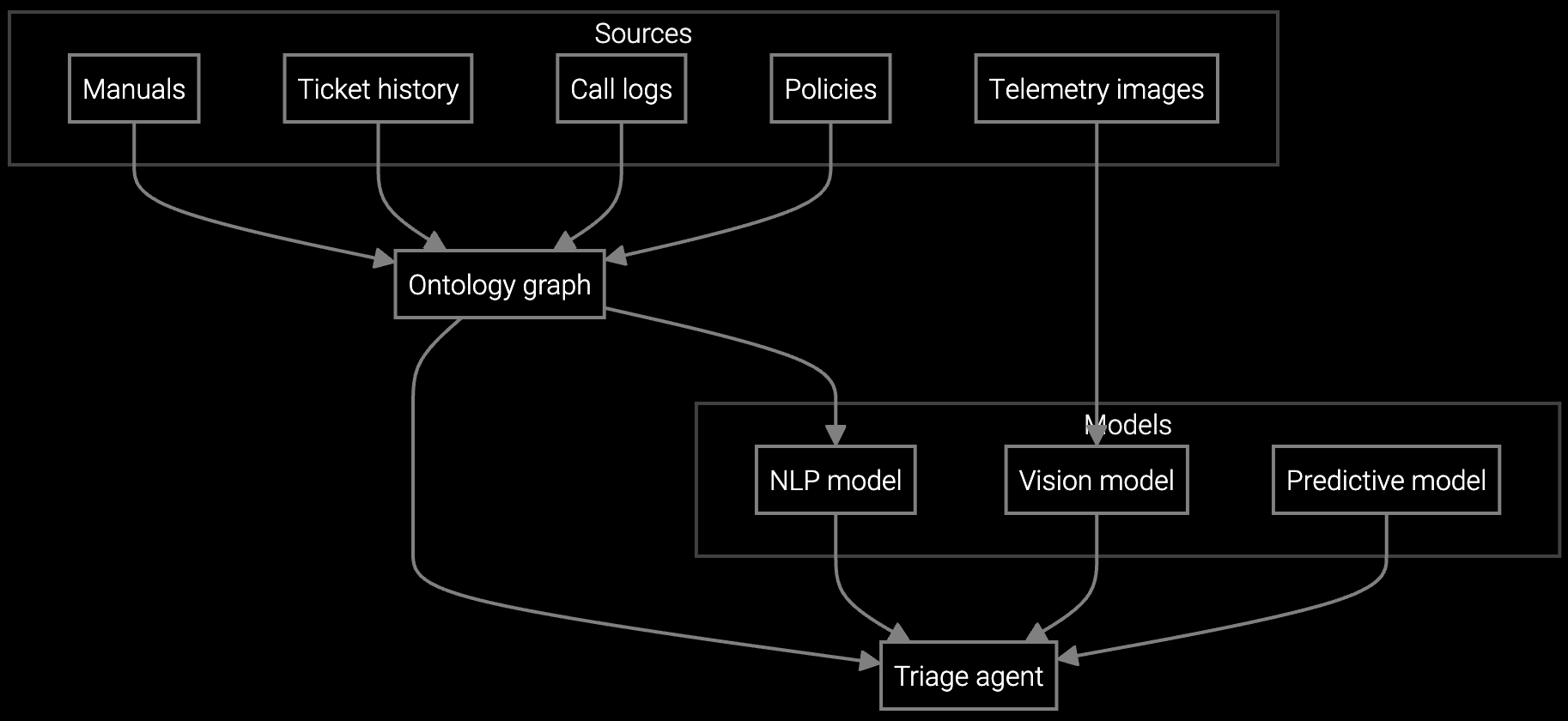

Autonomous case classification analyzes pump failures, CNC errors, and compressor symptoms to route cases with diagnostic context already attached.

Instantly generates case summaries from multi-channel history so agents understand equipment context without reading through years of service records.

AI reads incoming service emails about machinery issues and drafts responses using historical case data and troubleshooting knowledge bases.

Industrial equipment service centers handle diverse case types: CNC machine alignment errors, hydraulic pump leaks, PLC programming questions, compressor vibration diagnostics. Each equipment type has its own manuals, parts catalogs, and failure modes. Agents supporting a fleet of decades-old turbines and brand-new automation systems need instant access to equipment-specific knowledge.

The time savings compound when you run a 20-agent contact center. Cutting 6 minutes per case across 80 cases daily per agent yields 160 hours saved weekly. That capacity expansion absorbs seasonal spikes without hiring or prevents backlog from turning into SLA penalties. For OEMs supporting equipment with 10-30 year lifecycles, reducing handle time also reduces dependency on agents who hold years of accumulated product knowledge.

Most agents report 20-30% faster case resolution within the first two weeks as they learn to trust the AI sidebar for parts lookup and troubleshooting guidance. Full 35-45% reduction typically appears by week 4-6 once auto-documentation and case classification are fully adopted across all case types.

Yes. The platform ingests whatever documentation exists—PDF manuals, scanned schematics, past case notes—and builds a searchable knowledge base. For legacy equipment, historical case data becomes the primary knowledge source, capturing how past agents resolved similar issues even when official manuals are outdated or incomplete.

Track average handle time, cases resolved per agent per day, first contact resolution rate, and escalation rate. Also measure time spent on post-call documentation before and after AI adoption. These four metrics quantify both speed gains and quality improvements in a way that translates directly to cost per case and capacity planning.

Most industrial OEMs use the capacity gain to handle volume growth without hiring, absorb seasonal demand spikes, or reduce backlog rather than cutting headcount. The platform makes existing agents more productive, which typically means better service levels and faster response times rather than workforce reduction.

The AI presents step-by-step troubleshooting guides in the sidebar, with each step linked to relevant diagnostics or parts. Agents walk customers through the sequence while the AI queues up the next step and suggests parts to order based on symptoms. This guided workflow reduces escalations and ensures consistent troubleshooting quality across all agents.

Understanding and optimizing the issue resolution curve.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Calculate how much handle time you can recover in your service center with AI-powered case automation.

Schedule ROI Assessment