Fab downtime penalties and agent labor costs make contact center efficiency a margin imperative for semiconductor equipment OEMs.

Semiconductor OEMs reduce customer service costs 35-42% through AI automation. Savings come from lower AHT (18-25% reduction), improved FCR (12-18 point gain), and reduced agent headcount requirements while maintaining SLA compliance and fab customer satisfaction.

Semiconductor equipment support requires highly trained agents who understand process tools, recipes, and fab operations. High labor costs per case combined with rising case volumes create unsustainable cost per contact growth.

When agents lack instant access to equipment history, process recipes, and past failure modes, they provide incomplete answers. Fab customers call back repeatedly, multiplying handling costs and risking SLA penalties.

Agents search across disconnected systems—CRM, knowledge bases, equipment telemetry, parts databases—to answer single questions. Every extra minute of handle time scales linearly with agent headcount costs.

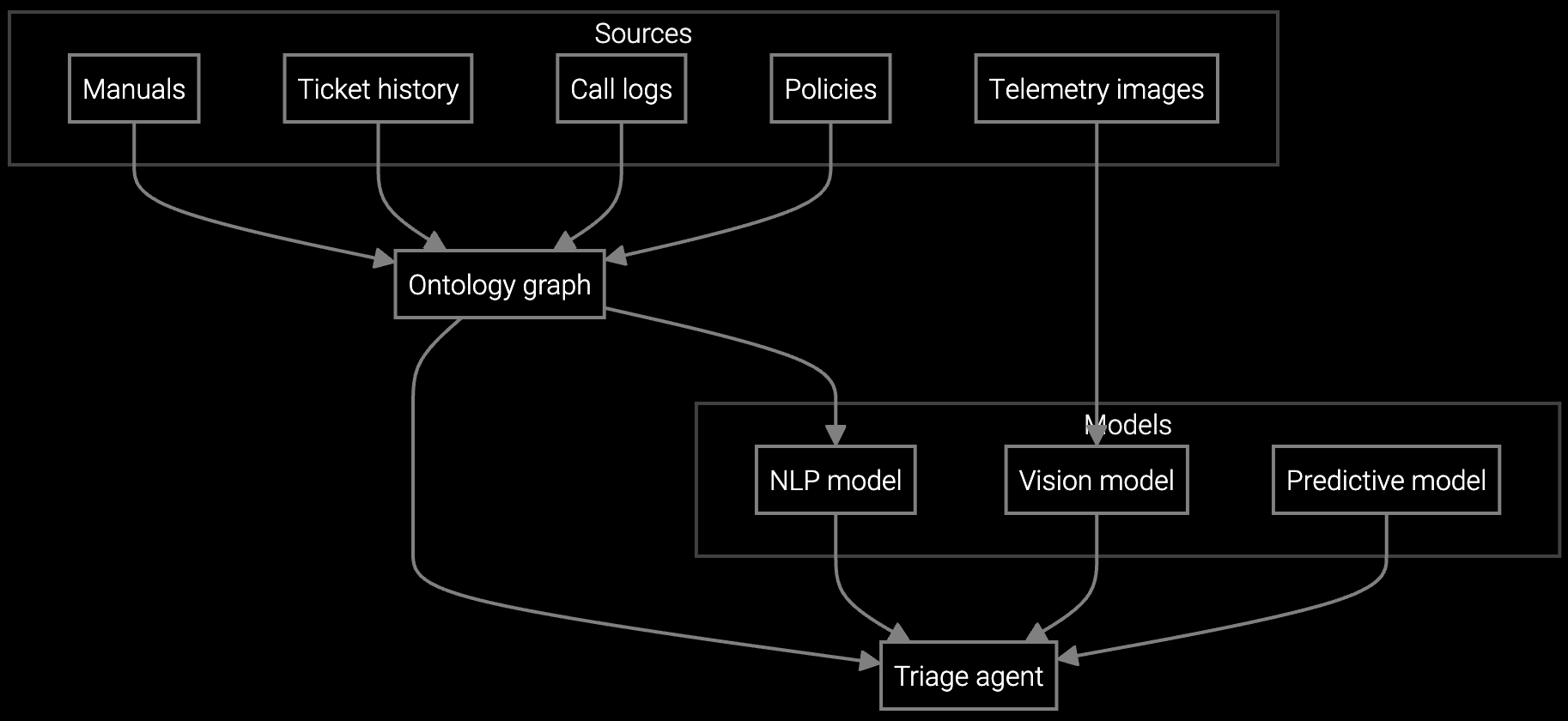

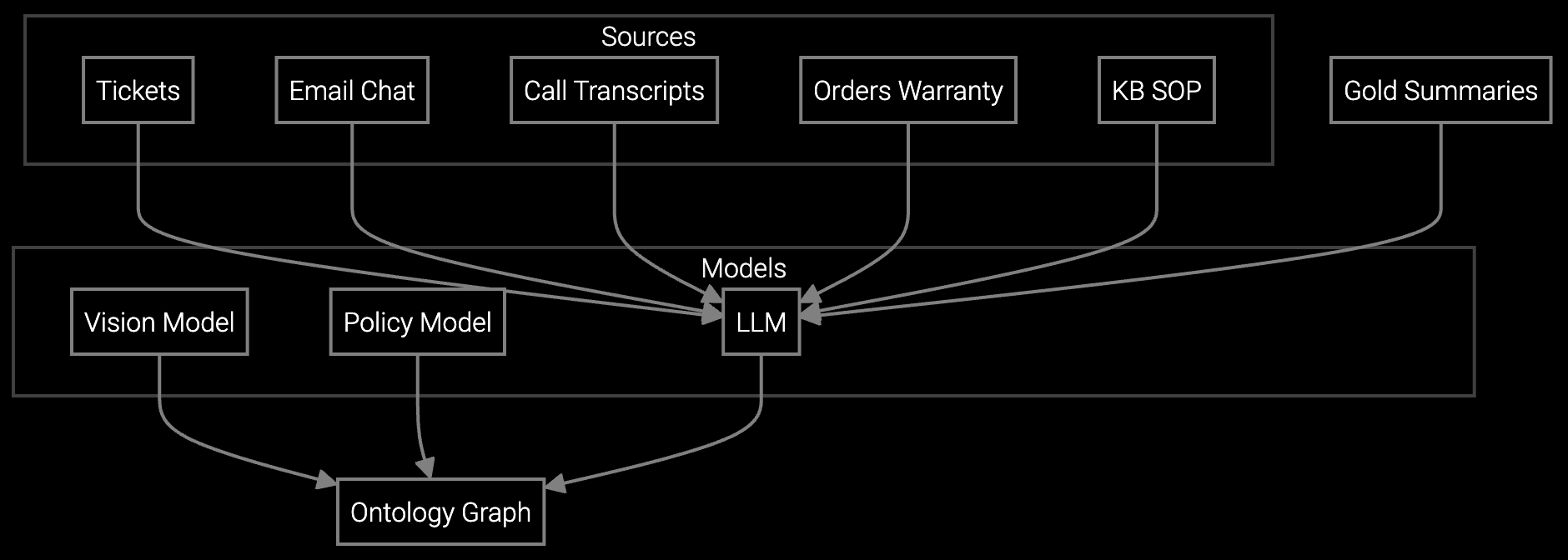

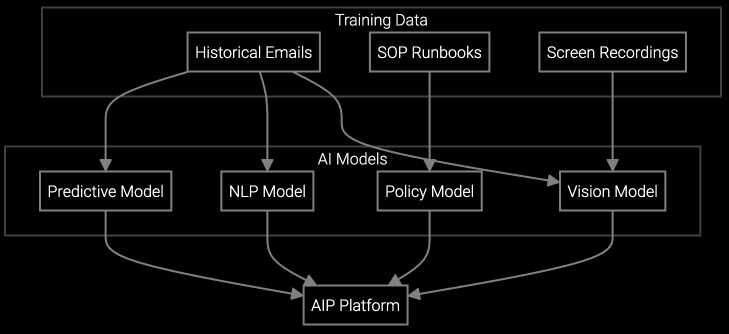

Bruviti's platform automates the knowledge retrieval, case classification, and response drafting workflows that consume agent time. The AI reads equipment telemetry, correlates symptoms with historical failure modes, and surfaces relevant troubleshooting steps—work that previously required agents to manually search five systems and interpret results.

The ROI logic is straightforward: lower AHT reduces the agent hours required per case volume. Higher FCR eliminates repeat contacts that multiply costs. Together, these gains allow semiconductor OEMs to serve growing fab customer bases without proportional headcount increases, directly protecting service margins.

Autonomous case classification for semiconductor equipment issues—correlating chamber symptoms, recipe parameters, and telemetry to route cases with diagnostic context already attached.

Instant case history summaries for fab customer accounts—agents see equipment install base, recent PM cycles, and open cases without reading through months of logs.

AI reads incoming fab customer emails, classifies by equipment type and urgency, and drafts responses using historical troubleshooting knowledge—reducing manual email handling by 60%.

Fab customers operate 24/7 production with million-dollar-per-hour downtime costs. They expect instant answers when lithography tools, etch chambers, or metrology systems show anomalies. Traditional contact centers can't scale expert-level support without unsustainable labor costs.

Semiconductor equipment complexity—process recipes, chamber configurations, consumable part lifecycles—means agents need deep technical knowledge. Training new agents takes 6-9 months, and turnover resets that investment. AI automation captures this expertise once, then scales it across the entire agent workforce without ongoing training overhead.

Most semiconductor equipment OEMs achieve payback in 8-14 months. Savings come from reduced agent headcount needs (or deferred hiring as case volumes grow), lower AHT multiplied across thousands of annual cases, and avoided SLA penalties from faster resolution. Initial investment covers platform licensing, integration with CRM and telemetry systems, and historical data ingestion for AI training.

Baseline your current fully-loaded agent cost (salary, benefits, overhead, tools) divided by annual case volume to get cost per contact. Measure current AHT and FCR. After AI deployment, track the same metrics. Every minute of AHT reduction translates directly to fewer agent hours needed. Every FCR percentage point gain eliminates repeat contacts. Multiply these efficiency gains by annual case volume to calculate total savings.

Both outcomes occur depending on business strategy. Semiconductor OEMs facing growing fab install bases typically use AI to serve more cases with existing agent teams, avoiding 15-25% headcount growth. OEMs optimizing for margin take some portion as direct headcount reduction through attrition. Most pursue hybrid strategies—modest headcount optimization while absorbing case volume growth without proportional hiring.

Track AHT (target 18-25% reduction), FCR (target 12-18 point gain), cost per contact (target 35-42% reduction), and agent utilization (cases handled per agent per day). Also monitor CSAT to ensure quality doesn't degrade—AI should maintain or improve customer satisfaction while driving efficiency. Compare these metrics monthly against pre-deployment baseline for rolling ROI calculation.

Calculate the cost trajectory under status quo: annual case volume growth rate multiplied by current cost per contact, compounded over 3-5 years. Add competitive risk—if rival OEMs deploy AI and achieve faster response times at lower cost, your fab customers will notice the service gap. Also factor knowledge loss risk as senior agents retire, taking irreplaceable troubleshooting expertise with them unless captured by AI.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

See the margin impact of AI automation for your semiconductor customer service operation.

Schedule ROI Analysis