When equipment downtime costs $1M per hour, every minute your contact center spends searching for answers directly impacts your customers' yield.

AI-assisted customer service reduces semiconductor OEM contact center costs by 35-45% through automated case triage, instant knowledge retrieval, and reduced escalations, while improving fab equipment uptime through faster technical resolution.

Agents spend 8-12 minutes per case searching across multiple knowledge systems to classify lithography tool errors, etch chamber alarms, or metrology anomalies before routing to specialized engineers.

Different agents provide different answers to the same EUV recipe drift question or FOUP contamination scenario, forcing fab engineers to call back multiple times and escalating the issue.

Process engineers fielding escalated cases from contact centers spend 30-40% of their time answering questions agents could resolve with better tooling, delaying customer issue resolution.

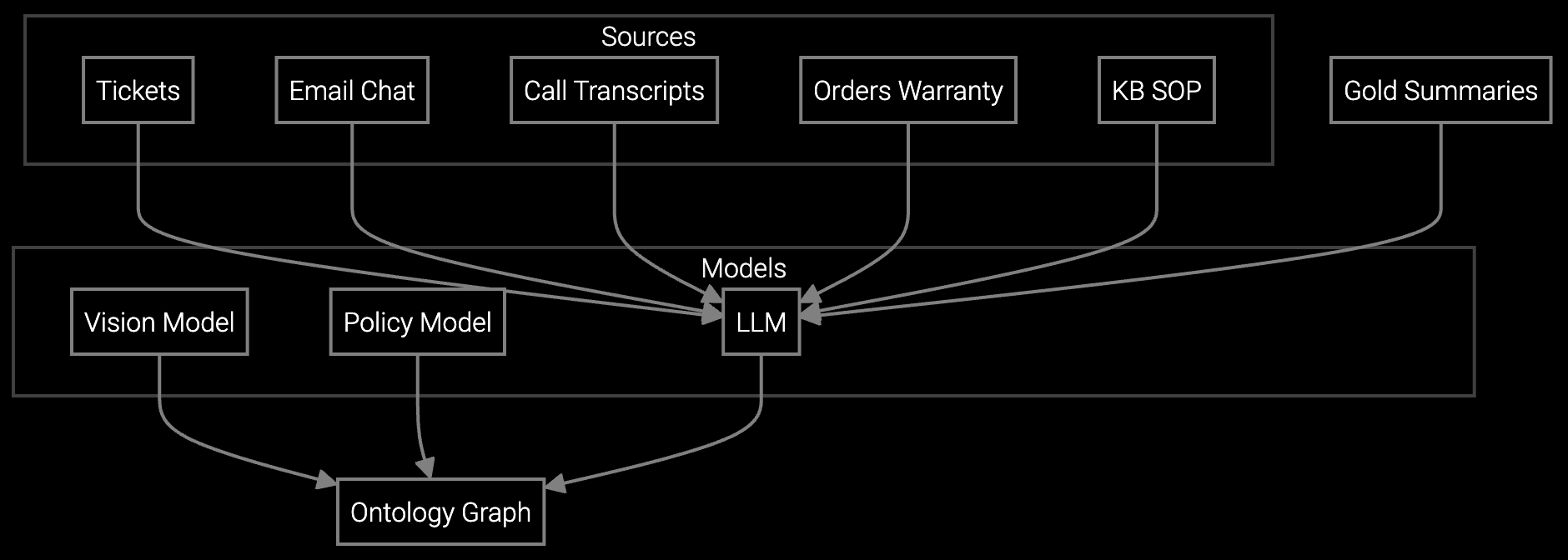

The ROI calculation for AI-assisted customer service centers on three cost drivers: handle time, escalation volume, and knowledge retrieval efficiency. Bruviti's platform integrates with existing CRM and ticketing systems via API, layering intelligent case triage and contextual answer retrieval on top of your current stack without requiring agents to learn new interfaces.

For semiconductor OEMs, the value multiplies because contact center speed directly impacts fab uptime. Automated classification routes chamber alarm cases to the right specialist instantly. Real-time knowledge retrieval pulls equipment-specific troubleshooting steps from historical case data, service bulletins, and process engineer notes. Agents resolve more cases on first contact, reducing costly repeat interactions and freeing engineering time for yield improvement work instead of answering repetitive questions.

Autonomous classification for lithography alarms, etch chamber errors, and metrology anomalies — routes cases to the right specialist with diagnostic context attached.

Instant case history summaries for fab engineers calling about equipment issues — agents understand context without reading through 15 prior interactions.

Automated email classification and response drafting for routine requests — chamber kit availability, PM schedule changes, spare parts ordering — reducing agent workload.

Semiconductor fabs operate at extreme precision with microscopic tolerances. When an EUV lithography tool throws an error or a deposition chamber drifts out of spec, every minute of delay costs the fab customer thousands in lost wafer throughput. Your contact center is the first line of defense — if agents can diagnose and resolve issues faster, you protect your customer's yield and reduce emergency escalations that pull process engineers away from optimization work.

The cost calculation shifts when you factor in fab downtime. A 10-minute reduction in Average Handle Time for tool-related cases doesn't just save contact center labor — it accelerates equipment restoration by 10 minutes per incident, multiplied across hundreds of monthly cases. That speed translates directly to improved OEE for your customers, which strengthens contract renewals and reduces churn risk.

Track three cost metrics: Average Handle Time reduction (target 35-40%), escalation volume decrease (target 50-60%), and First Contact Resolution improvement (target 28-35%). Multiply handle time savings by loaded agent cost per hour, and escalation savings by engineer hourly rate. Include downstream value from faster fab issue resolution — even small speed improvements compound across hundreds of monthly cases. Most semiconductor OEMs see payback within 6-9 months when factoring in both direct labor savings and customer satisfaction improvements that drive contract renewals.

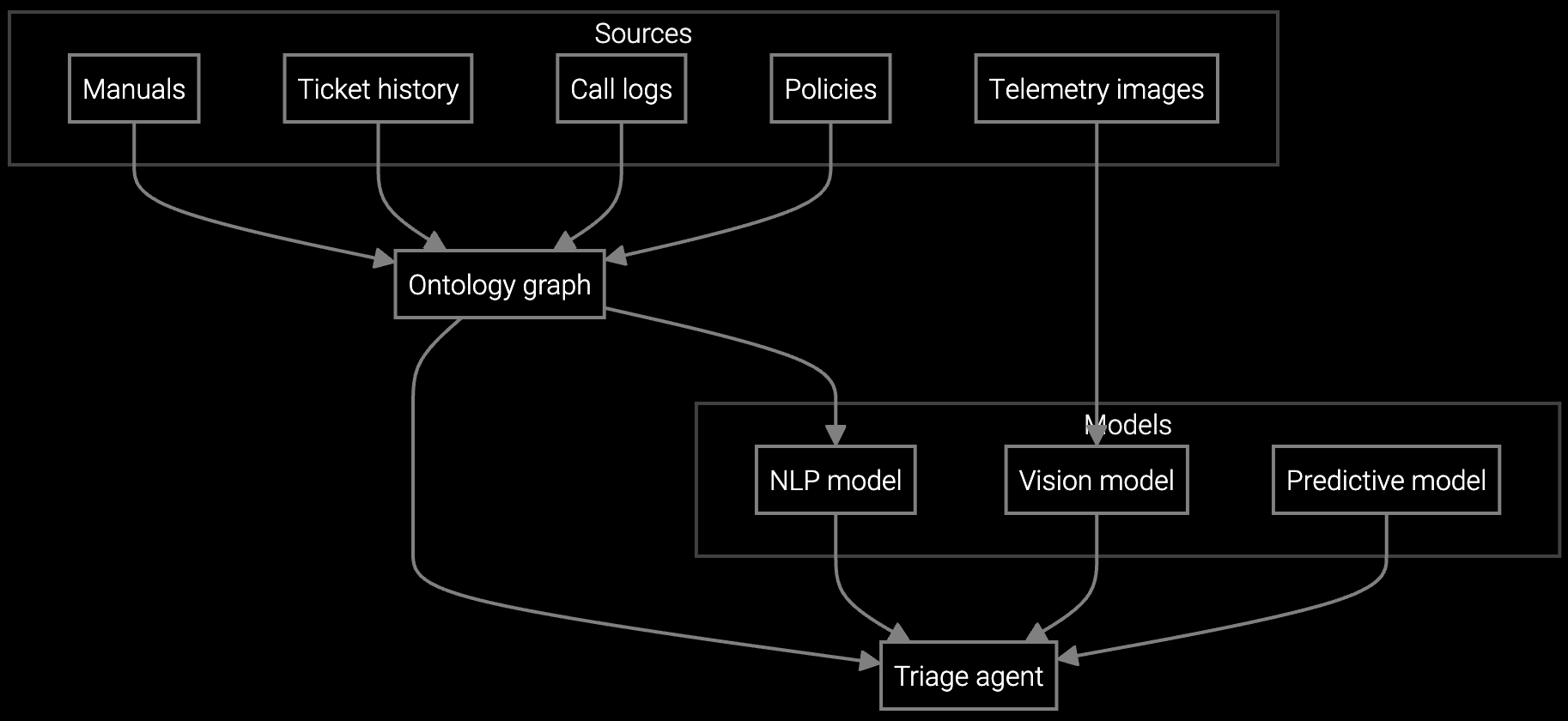

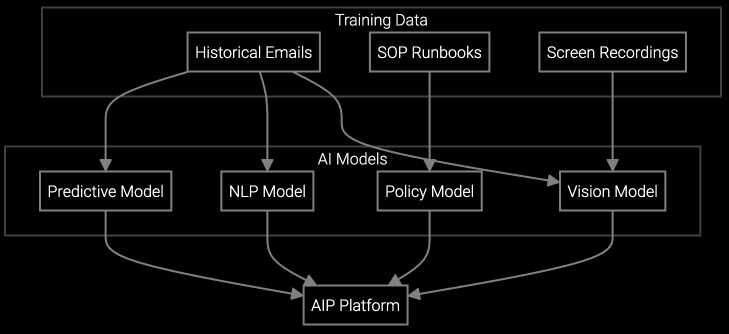

API integration with your existing CRM, ticketing system, and knowledge base — typically Salesforce, ServiceNow, or Zendesk. The platform ingests historical case data, service bulletins, and equipment documentation to train classification models. Python SDKs allow your team to customize routing logic based on equipment type, alarm code, or customer tier. Most deployments complete initial integration in 4-6 weeks with production rollout phased by case type to minimize agent retraining overhead.

Yes. The platform exposes Python SDKs for model fine-tuning on your proprietary equipment data — lithography tool logs, etch chamber recipes, metrology sensor outputs. You control the training data and can retrain models as new equipment generations launch or process recipes evolve. No vendor lock-in — models run in your environment and you own the training artifacts. This customization is critical for semiconductor OEMs where each tool generation has unique failure modes and diagnostic logic that generic models cannot capture.

Start with operational metrics: Average Handle Time, First Contact Resolution rate, and escalation volume per week. Convert these to financial impact by multiplying time savings by loaded labor costs for agents and engineers. Add customer impact metrics: equipment downtime minutes saved per case, and fab engineer satisfaction scores with contact center responsiveness. For executive reporting, calculate total cost of contact (labor + technology) per case resolved, and track the trend quarterly. Most CFOs want to see payback period under 12 months, which is achievable when you include both direct cost savings and customer retention value.

Deploy in phases by case type — start with high-volume, lower-complexity cases like PM schedule requests or spare parts inquiries where AI classification is most accurate. Agents see AI suggestions as sidebar recommendations in their existing interface, maintaining control over final decisions. Track agent acceptance rate of AI recommendations as a leading indicator of trust. Once agents see time savings on routine cases, expand to more complex equipment diagnostics. This gradual rollout minimizes training overhead and allows you to refine models on real cases before scaling across all case types.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

See the ROI model customized for your case volume, agent count, and equipment portfolio.

Request ROI Analysis