Incomplete serial number records and missing configuration data cost appliance OEMs millions in lost service contract revenue.

Implement asset tracking for appliances using REST APIs that ingest serial numbers, model data, and IoT telemetry. Python SDKs handle configuration drift detection and contract attachment without vendor lock-in.

Missing serial numbers and installation dates prevent proactive outreach. Legacy equipment registered with phone support lacks model details, firmware versions, or warranty status.

Installed firmware versions diverge from records. Connected appliances update automatically, but backend systems show stale data, breaking troubleshooting accuracy.

Service contract expiration dates aren't tracked consistently. Sales teams lack visibility into renewal candidates, leaving revenue on the table as warranties lapse unnoticed.

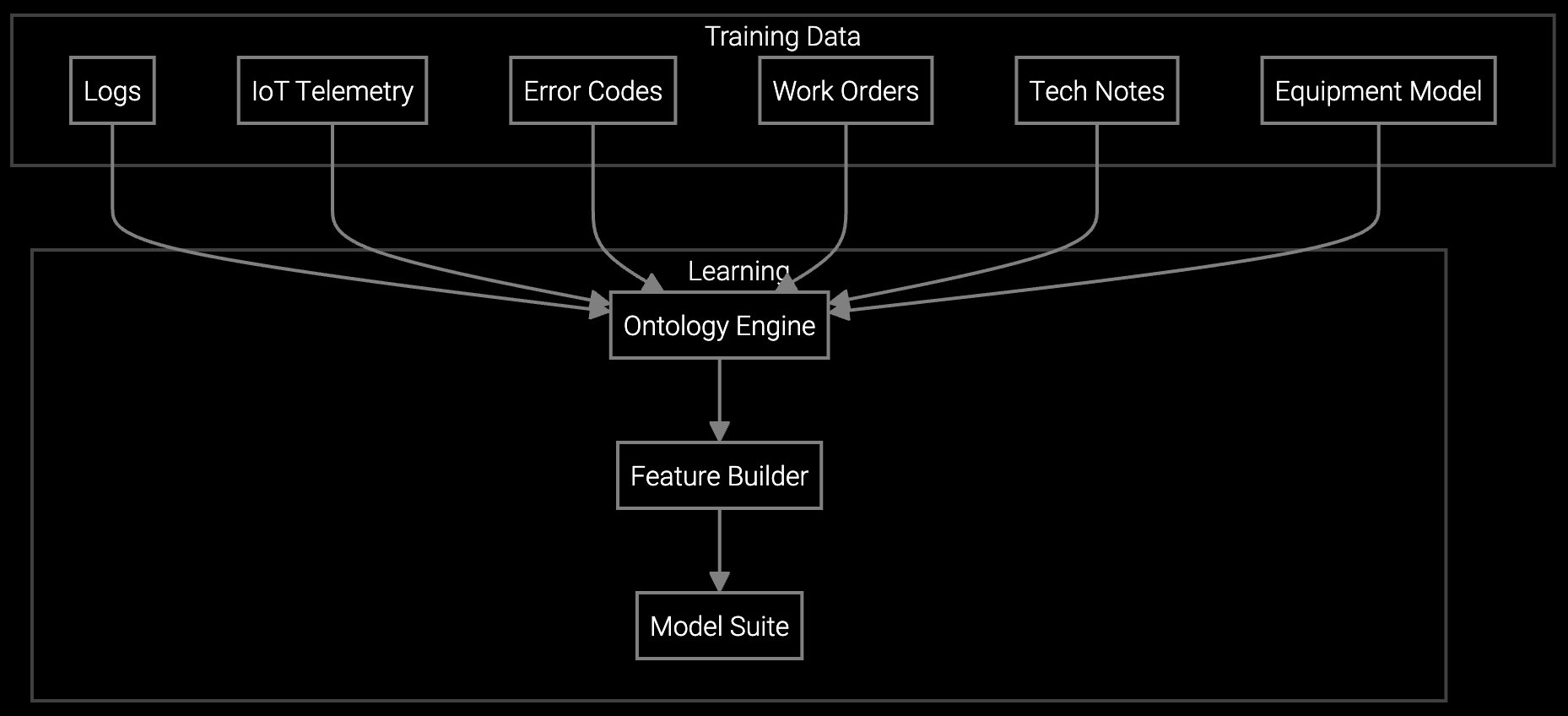

Bruviti's headless asset registry ingests product registration data, IoT telemetry, and service history via REST endpoints. Python SDKs parse serial number formats, normalize model identifiers, and detect configuration changes without requiring proprietary client libraries. TypeScript bindings integrate with existing CRM and ERP systems using standard OAuth 2.0 authentication.

The platform tracks firmware versions, replacement part installations, and warranty milestones in a normalized schema. Developers write custom lifecycle rules using Python—flagging appliances approaching end-of-support, identifying upsell candidates based on usage patterns, or triggering proactive maintenance alerts when telemetry indicates impending failures. Data stays in your infrastructure; the platform provides the intelligence layer without data lock-in.

Track refrigerator compressor performance and HVAC cycle times in virtual models, enabling proactive maintenance before customer-facing failures occur.

Analyze IoT streams from dishwashers and washing machines to identify anomalies like valve leaks or motor bearing wear before catastrophic failures.

Identify recurring failure modes across the installed base—like ice maker valve defects or control board failures—to drive engineering improvements.

Appliance manufacturers face unique tracking challenges: decades-long product lifespans, consumer-owned installations without IT oversight, and a mix of connected and legacy equipment. The asset registry must handle serial number formats spanning 30+ years of products, normalize model identifiers that changed with acquisitions, and reconcile IoT telemetry streams with phone-based registration data.

Connected refrigerators, HVAC systems, and water heaters transmit real-time usage data, but 60% of the installed base remains offline. The platform bridges this gap by enriching sparse registration records with inferred data—estimating installation dates from warranty activation, predicting usage patterns from geographic location and household size, and flagging renewal candidates based on typical replacement cycles for each product category.

The platform provides REST endpoints for bulk asset imports via CSV or streaming ingestion via webhook. Python SDK includes parsers for common serial number formats and model identifier schemas. OAuth 2.0 authentication integrates with existing identity providers, and rate limits scale to handle seasonal registration spikes during holiday purchasing periods.

Subscribe to configuration change webhooks that fire when IoT telemetry reports firmware updates or part replacements. The Python SDK includes a comparison function that diffs reported state against expected state, returning a list of discrepancies. You define tolerance thresholds—minor version updates may not require record updates, but major firmware changes or component swaps should trigger immediate sync.

Yes. The platform exposes a rules engine where you write Python functions that evaluate asset records. Define conditions like "flag refrigerators older than 8 years with no service contract" or "alert when HVAC systems approach end-of-support dates." Rules run in your infrastructure using open-source libraries; no proprietary runtime required. Export rules as portable Python modules to avoid lock-in.

The asset registry stores contract start dates, durations, and renewal terms. Query the API for assets with contracts expiring in the next 90 days, filtered by product category or geography. Integrate with your CRM to automatically create renewal opportunities. The platform calculates lifetime value metrics by correlating service history with contract status, helping prioritize high-value accounts.

Raw asset records—serial numbers, installation addresses, customer PII—remain in your database. The platform ingests anonymized identifiers and telemetry streams, returning enriched metadata like predicted failure dates or upsell scores. You control data residency and can run the intelligence layer on-premises. API responses never include PII unless explicitly requested via authenticated endpoints.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

Get API documentation, Python SDK examples, and architecture guidance tailored to appliance installed base management.

Talk to an Engineer