When your customers call about a broken refrigerator, different agents shouldn't give them different answers.

Leading appliance OEMs consolidate knowledge into a single AI system that delivers consistent answers across agents. This eliminates response variability, reduces handle time, and protects warranty margins by ensuring every customer interaction follows best-practice diagnostics from the first contact.

Agents searching through disconnected systems give different troubleshooting steps for identical symptoms. Customers call back when the first agent's advice doesn't work, driving up contact volume and eroding trust.

Agents toggle between manuals, internal wikis, and case histories to find the right answer. This search time adds minutes to every call while the customer waits, inflating Average Handle Time across the contact center.

Without instant access to product history and service contracts, agents miss opportunities to recommend maintenance plans or replacement parts. Every call is a potential revenue moment lost to knowledge gaps.

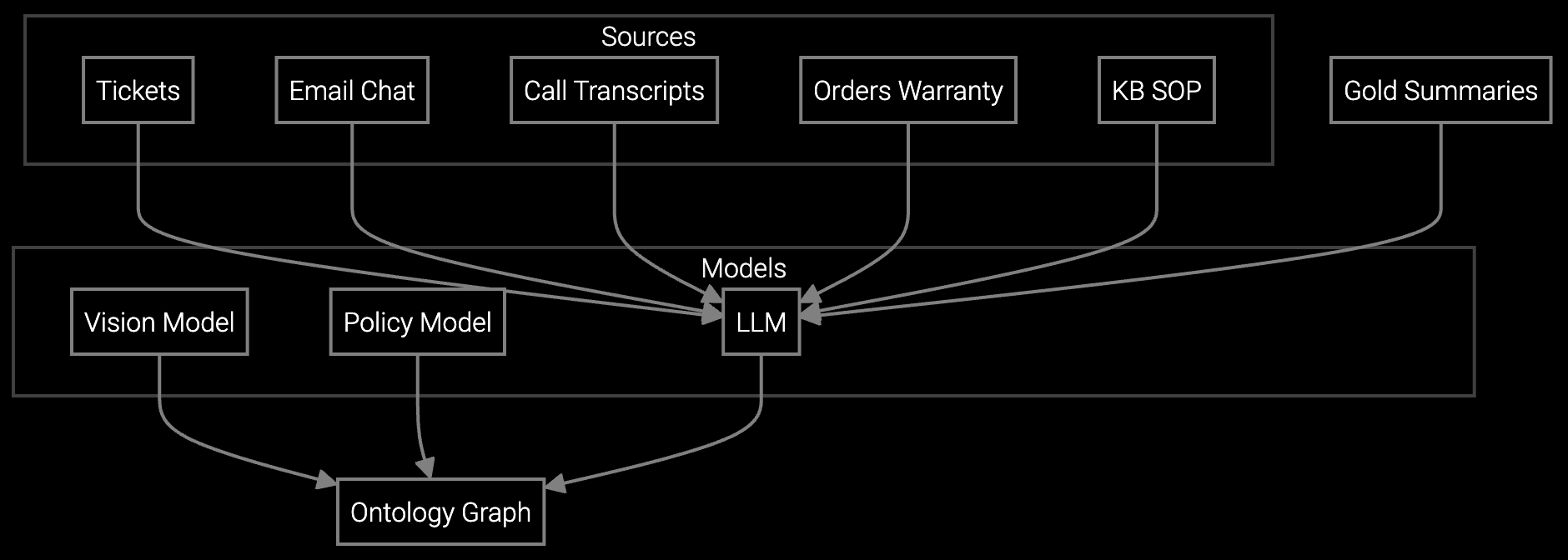

Top-performing appliance manufacturers consolidate decades of service manuals, IoT error codes, and case resolution patterns into a single AI knowledge system. When a customer describes a symptom—"My refrigerator isn't cooling"—the platform instantly retrieves the diagnostic tree specific to that model, warranty status, and failure history. Every agent sees the same step-by-step guidance, eliminating variability.

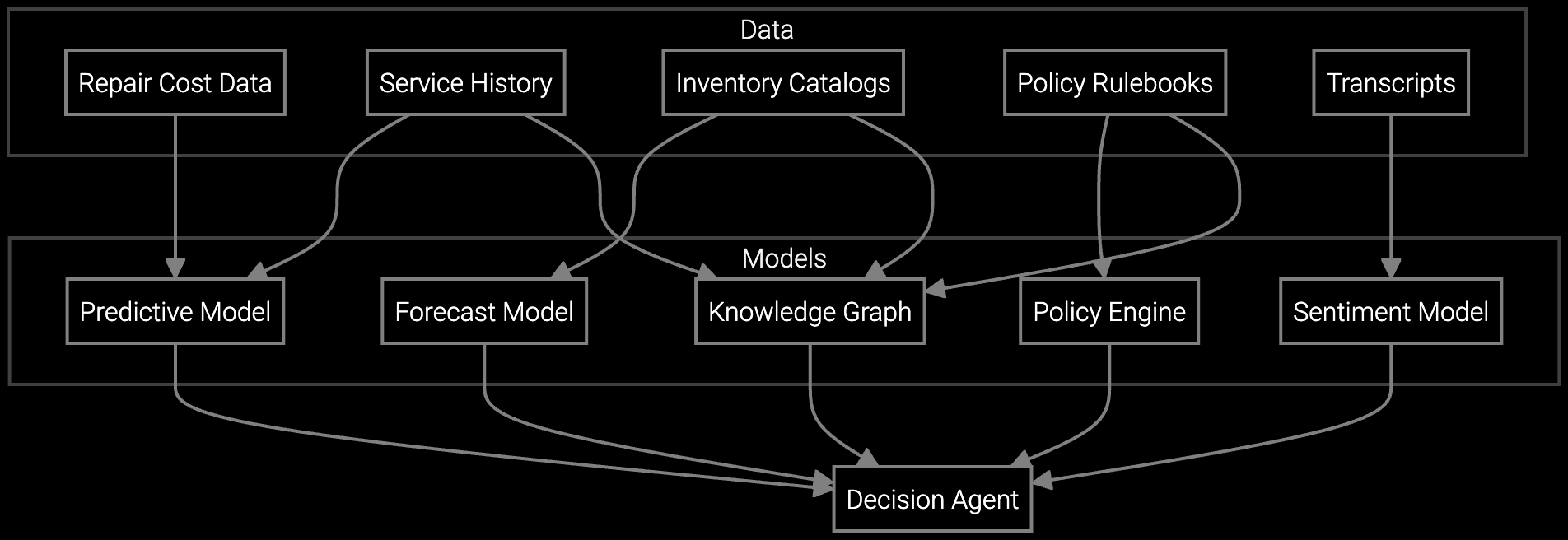

Bruviti's platform ingests appliance telemetry from connected devices, warranty claims history, and technician service notes to build product-specific intelligence. The system surfaces the most likely root cause based on symptom patterns across millions of units, then guides agents through verification steps that maximize first-call resolution. This approach transforms contact centers from reactive cost centers into strategic assets that protect warranty margins and identify upsell opportunities in real time.

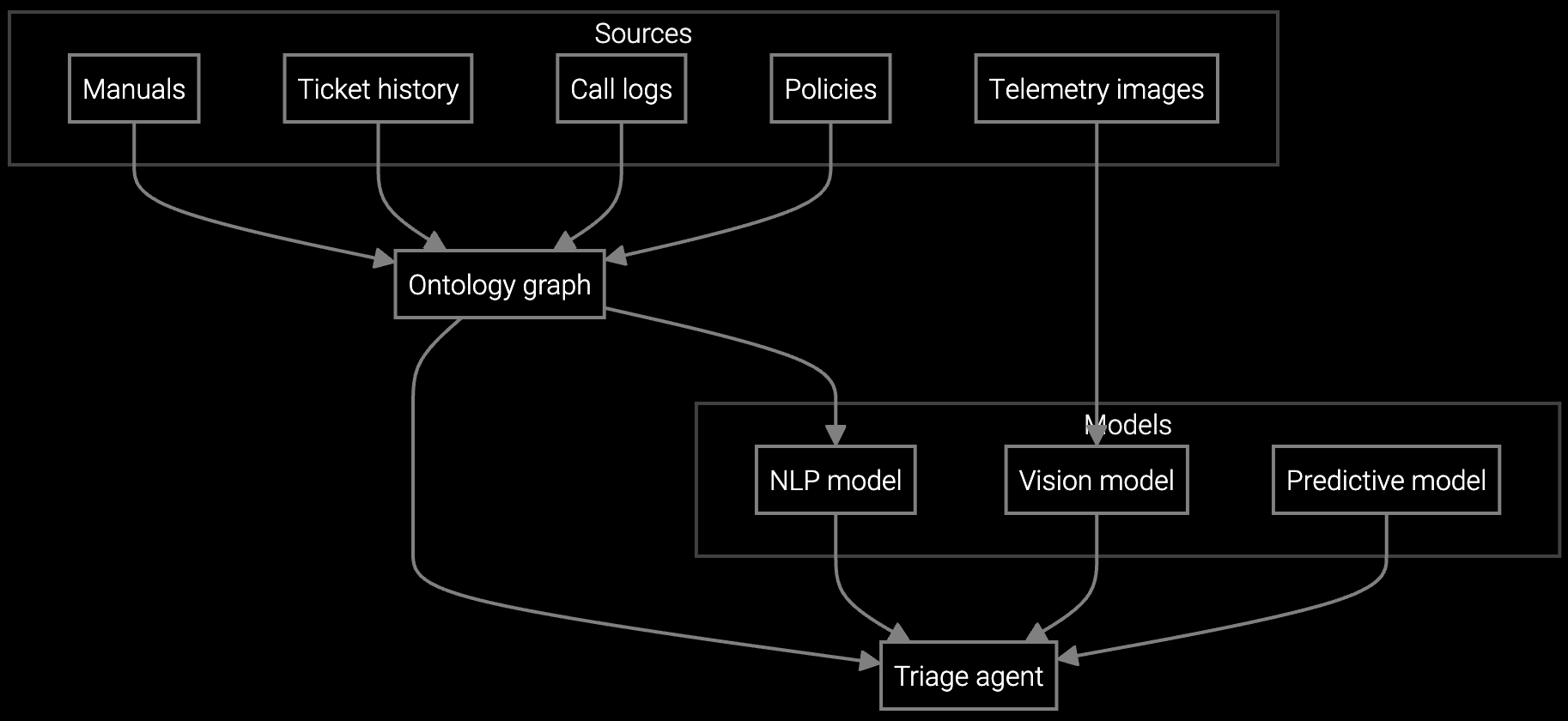

AI analyzes customer symptom descriptions and appliance error codes to route cases to the correct resolution path—self-service, agent-assisted, or technician dispatch—before the call begins.

Instantly generates case summaries from prior emails, chat logs, and service history so agents understand context within seconds instead of reading through fragmented records.

AI evaluates appliance age, repair history, and part availability to recommend the most cost-effective resolution—protecting warranty reserves while maintaining customer satisfaction.

Appliance manufacturers operate on thin margins where every service dollar counts. When a customer's refrigerator stops cooling or their washer won't drain, they expect immediate resolution—not a callback tomorrow. Inconsistent agent responses drive repeat contacts, inflate handle times, and damage brand perception at the moment it matters most: when something breaks.

Your contact center handles hundreds of thousands of cases annually across decades of product models, each with unique error codes and failure modes. Connected appliances add IoT telemetry layers that agents struggle to interpret alongside traditional symptom descriptions. Without a unified knowledge system, response quality depends on which agent answers—creating variability that costs you in warranty reserves, customer satisfaction, and service contract renewals.

The root cause is fragmented knowledge distribution. Service manuals, warranty policies, troubleshooting guides, and product history live in separate systems. Agents search through multiple sources during calls, and different agents find different information—or give up at different points. This creates response variability where identical symptoms receive different guidance depending on who answers.

Top performers consolidate knowledge into a single AI-powered system that surfaces the right diagnostic path instantly. Instead of agents searching, the system retrieves model-specific troubleshooting steps, warranty status, and failure history in under two seconds. This eliminates search time while ensuring agents follow the best-practice diagnostic sequence that maximizes first-call resolution.

Callbacks happen when the first agent provides incomplete or incorrect troubleshooting steps. Without access to comprehensive failure pattern data, agents may skip verification steps or miss model-specific quirks. When the customer's issue persists, they call again—often getting a different agent who provides different guidance. This cycle inflates contact volume and damages trust in your brand's service capability.

Implementation typically takes 8-12 weeks for initial deployment on high-volume product categories. The platform ingests existing service documentation, warranty claims data, and IoT telemetry to build appliance-specific knowledge models. Most OEMs see measurable improvements in FCR and AHT within 30 days of agent rollout, with full ROI demonstrated within the first quarter.

Track three metrics: First Contact Resolution rate, Average Handle Time, and warranty cost per unit. When agents follow consistent diagnostic paths, FCR rises 25-30% because fewer cases require callbacks. AHT drops 35-40% as agents stop searching across systems. Warranty costs decline as better triage reduces unnecessary part replacements and technician dispatches. Together, these metrics typically deliver $8-12 cost reduction per contact.

Transforming appliance support with AI-powered resolution.

Understanding and optimizing the issue resolution curve.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Discover how leading appliance OEMs standardize agent knowledge to protect warranty margins and improve customer satisfaction.

Schedule Demo