Heavy machinery breakdowns cost customers thousands per hour—your agents need instant answers, not a scavenger hunt.

Industrial equipment service agents handle complex cases across 10+ systems while customers wait. AI-powered workflow automation consolidates equipment history, parts data, and service manuals into a unified interface, enabling agents to resolve cases in minutes instead of hours without switching screens.

Agents toggle between CRM, ERP, parts catalogs, service manuals, and warranty systems to answer one customer question. Each screen switch adds friction, extends handle time, and increases error risk as context gets lost between applications.

Finding the right troubleshooting guide for a 15-year-old compressor means searching PDF libraries, outdated wikis, and emailing senior agents. Critical equipment context lives in scattered systems, forcing agents to reconstruct machine history from scratch every time.

Agents spend half their time on data entry—copying serial numbers, filling case notes, updating ticket status, and manually routing escalations. This drudgery burns out experienced agents and leaves less time for actual problem-solving with customers.

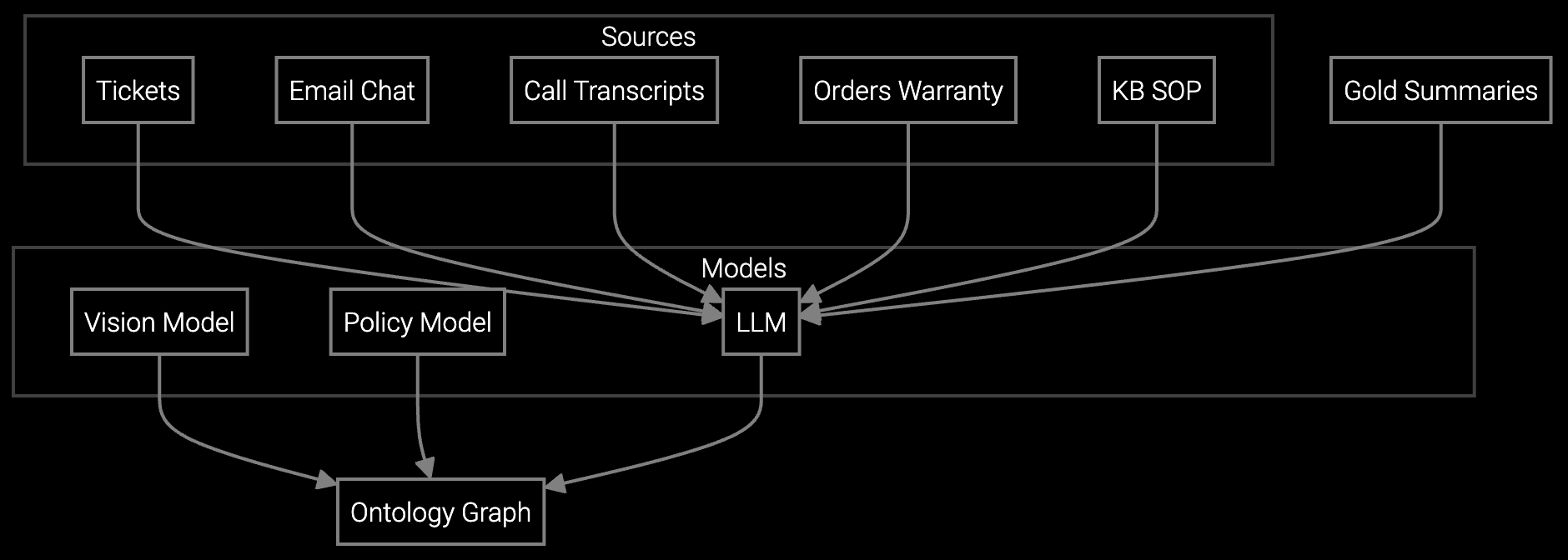

The platform consolidates all case resolution data into a single agent interface. When a customer calls about a malfunctioning CNC machine, the agent sees full equipment history, active service contracts, relevant technical bulletins, available replacement parts, and AI-generated troubleshooting steps—all without leaving the ticket screen.

AI automation handles repetitive workflow steps while agents focus on customer interaction. The system auto-populates case details from voice transcripts, suggests resolution paths based on similar historical cases, orders parts with one click, and routes complex issues to specialized teams with full diagnostic context already attached.

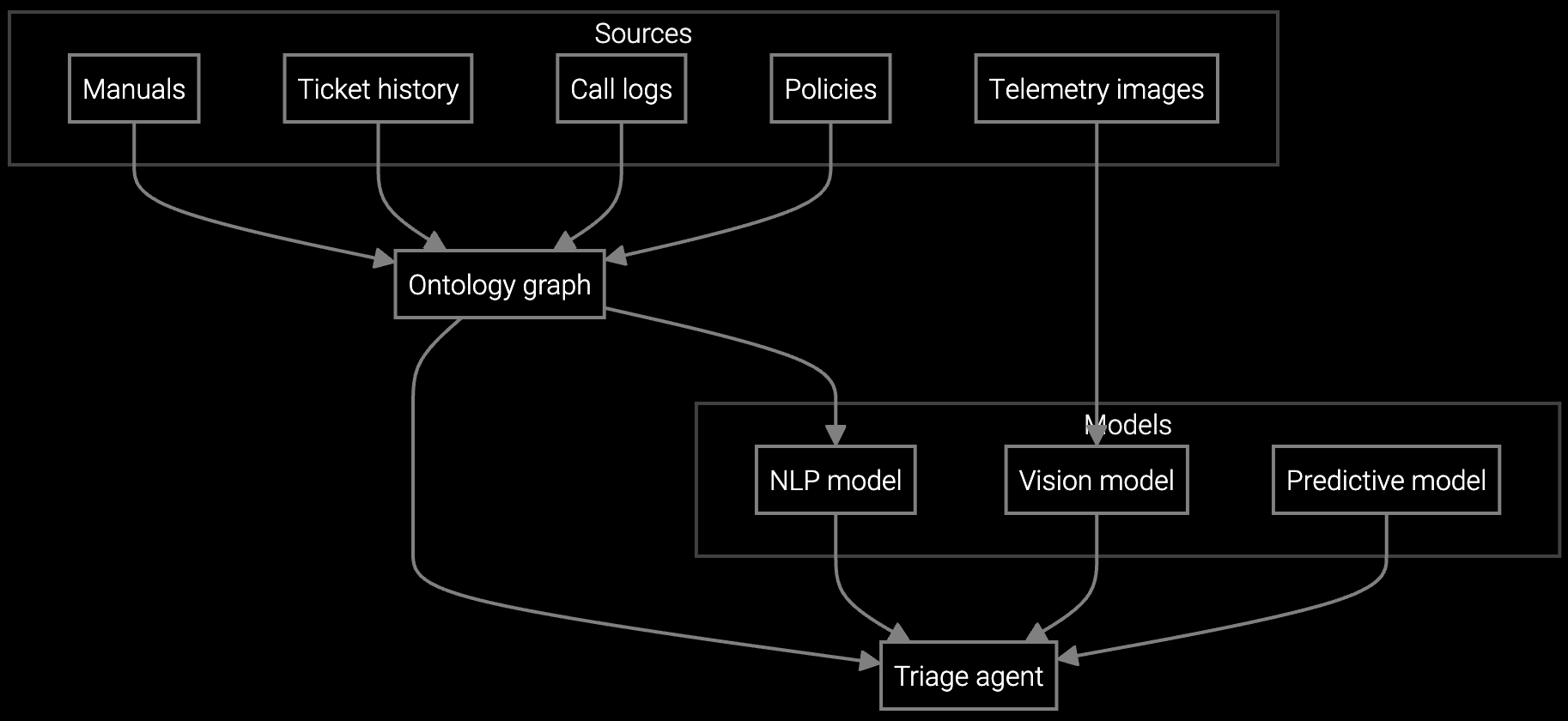

Automatically classify pump failure symptoms, correlate with vibration sensor data, and route cases to hydraulics specialists with diagnostic context.

Generate instant summaries from months of email threads and service logs so agents understand turbine maintenance history without reading 50 messages.

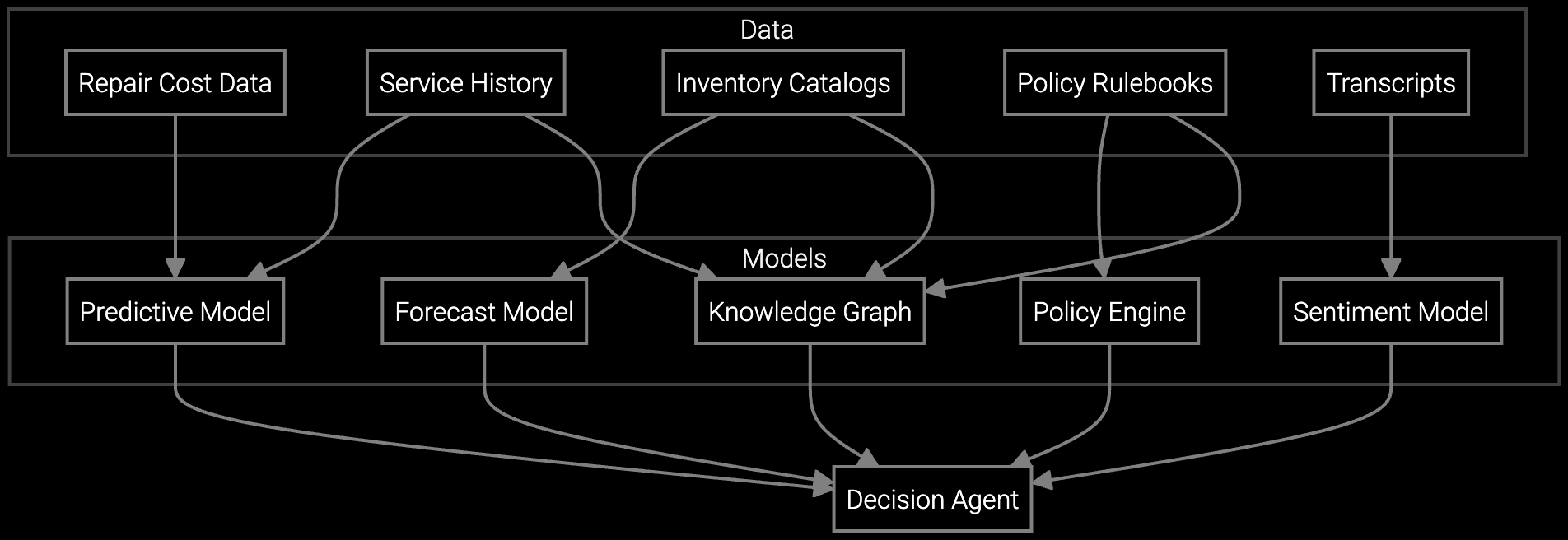

Analyze compressor age, failure history, and part costs to recommend the most cost-effective resolution path for manufacturing equipment.

Industrial equipment service demands instant access to decades of product data. A customer calling about a 20-year-old injection molding machine expects the agent to know its modification history, recall bulletins, compatible retrofit parts, and documented failure patterns—information scattered across legacy systems and retired paper archives.

Equipment deployed in remote factories means agents must diagnose issues remotely, walking customers through sensor readings and visual inspections over the phone. The platform surfaces relevant troubleshooting procedures based on equipment type, failure symptoms, and operational context, turning generalist agents into effective remote diagnosticians without years of field experience.

The platform ingests scanned service manuals, parts catalogs, and historical case notes to build searchable knowledge bases for older equipment. Agents can ask natural language questions like "bearing replacement procedure for 1998 Model X compressor" and receive relevant excerpts from archived PDFs. Over time, the system learns which legacy documentation patterns apply to recurring issues.

Agents always retain decision authority. The system presents recommended resolution steps with confidence scores—when confidence is low, it surfaces multiple options with explanatory context rather than forcing a single path. Agents can override AI suggestions, and those manual interventions become training data that improves future accuracy for similar edge cases.

Most agents become productive within hours because the interface eliminates complexity rather than adding it. Instead of learning 12 different system logins and navigation patterns, agents work from one screen with AI surfacing relevant information automatically. Initial training focuses on validating AI recommendations and handling exception scenarios rather than memorizing where data lives.

Automation amplifies existing knowledge rather than replacing it. Junior agents gain access to resolution patterns from thousands of historical cases, enabling them to handle routine issues that previously required senior staff. Experienced agents focus their expertise on complex diagnostics and customer relationship management instead of repetitive lookups, improving both job satisfaction and service quality.

The platform connects to ERP and CRM systems via APIs to verify entitlements, check parts inventory, and update case status in real time. Agents see contract coverage and available service hours directly in the ticket interface, eliminating manual entitlement lookups. Parts ordering and warranty claims submission happen with one click, auto-populating forms with equipment serial numbers and failure codes from the active case.

Understanding and optimizing the issue resolution curve.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Watch how agents resolve industrial equipment cases in one screen instead of twelve.

Schedule Demo