Equipment with 20-year lifecycles demands instant access to decades of service data agents currently can't find.

Unify scattered service data into a single interface with AI-powered search. Agents instantly retrieve equipment history, manuals, and telemetry without switching between systems, reducing handle time and improving first-contact resolution.

Agents toggle between ERP, CRM, legacy mainframe terminals, and PDF manuals to answer a single customer question about a CNC machine installed in 2008. Each lookup adds time.

Looking up error codes, part compatibility, or past service bulletins requires keyword searches across outdated documentation that may not match current equipment revisions or configurations.

Different agents apply different troubleshooting sequences. Without unified guidance, customers receive varying quality of support depending on which agent answers their call or email.

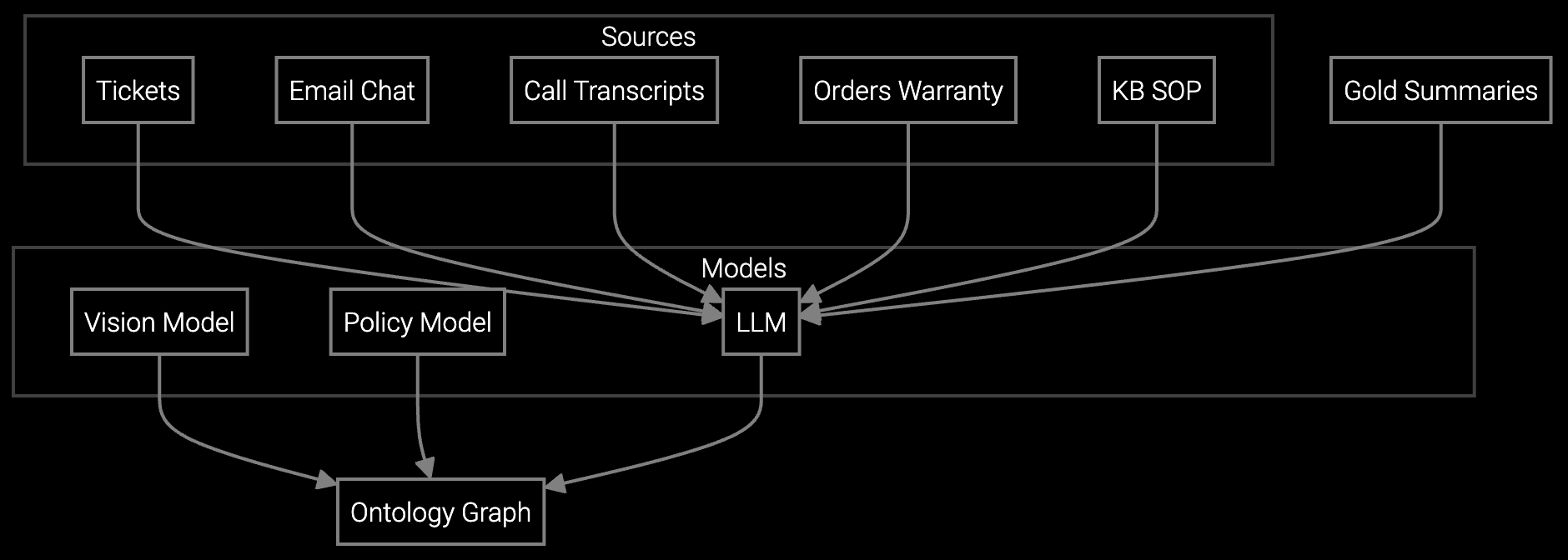

The platform eliminates swivel-chair work by surfacing equipment history, service bulletins, parts data, and telemetry in one interface. Natural language search replaces keyword hunting—agents type "VFD fault E304 on Model 7200" and receive root cause analysis, recommended parts, and past case resolutions instantly.

Case notes auto-populate from agent interactions and linked data sources. Agents review and approve suggested responses rather than drafting from scratch. For industrial equipment with long lifecycles, the system correlates decades of service data to surface relevant fixes for aging machinery without requiring agents to remember legacy models.

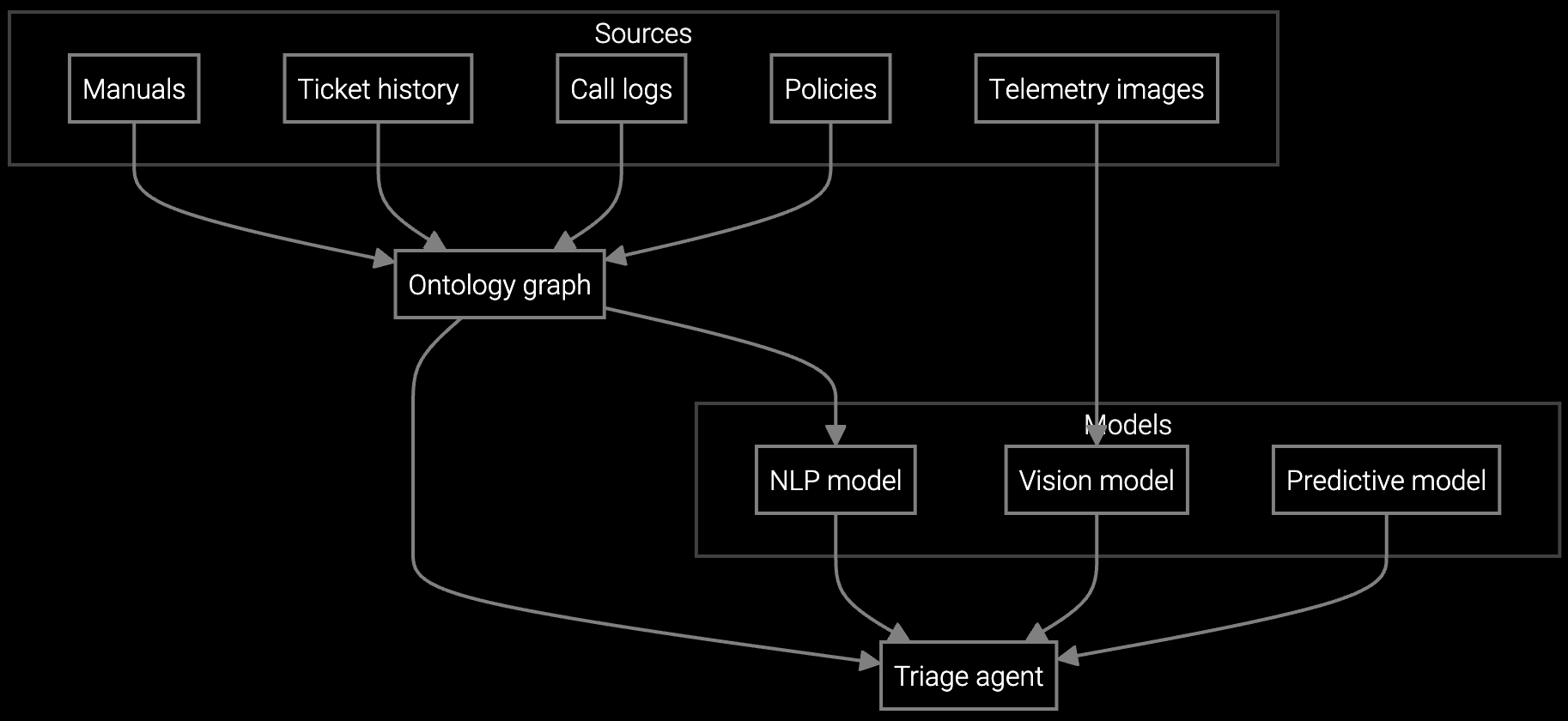

Autonomous case classification analyzes pump vibration data, correlates error codes, and routes issues to hydraulic specialists with diagnostic context.

Instantly generates case summaries from customer emails, maintenance logs, and call transcripts for turbines with 15-year service histories.

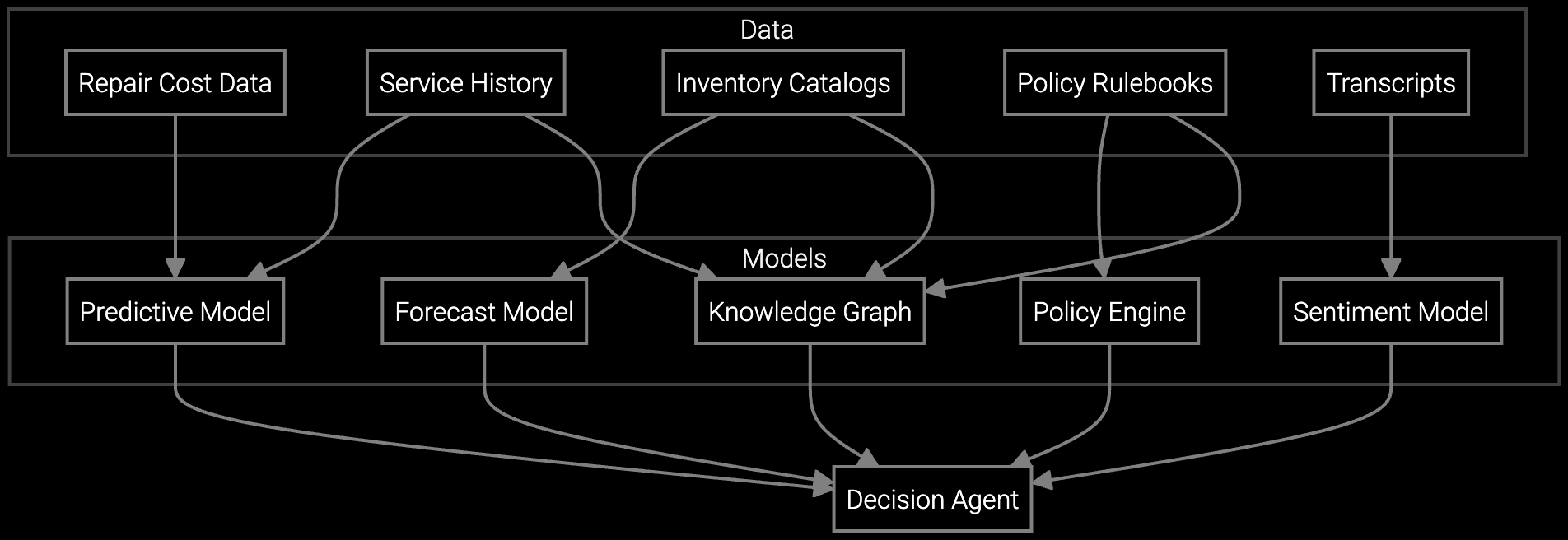

AI analyzes failure modes, compressor part costs, and equipment age to recommend the most cost-effective resolution path for industrial customers.

Industrial OEMs support machinery deployed 15-30 years ago with equipment configurations that no longer match current documentation. Agents need instant access to archived service bulletins, obsolete part cross-references, and historical case resolutions for legacy CNC machines, turbines, or material handling systems.

The platform ingests data from SCADA systems, PLC logs, and sensor telemetry to correlate equipment behavior with known failure patterns. When a customer reports a compressor vibration anomaly, agents see past cases with identical sensor signatures along with parts ordered and resolution outcomes without searching archived databases manually.

The AI indexes all service bulletins, manuals, and case histories regardless of format or age. Agents type questions like "hydraulic leak on 2005 Model 3400" and the system retrieves relevant documents, cross-referenced parts, and similar resolved cases without requiring exact keyword matches. It handles synonym variations and legacy model numbers automatically.

Yes. The unified interface provides deep links back to source systems like ERP, CRM, or telemetry dashboards when agents need full detail. The platform surfaces the most relevant data in one view but doesn't lock agents out of underlying systems when edge cases require direct access.

Agents review and approve all suggestions before communicating with customers. The system flags confidence levels for each recommendation. When agents correct an AI suggestion, that feedback trains the model to improve future accuracy for similar cases. Agents remain in control of final decisions.

Most agents become productive within one week. The interface uses natural language input similar to search engines, requiring minimal training. Agents don't need to learn complex query syntax or navigate nested menu structures—they ask questions and the system retrieves answers.

The platform handles both. For email cases, it auto-classifies incoming messages, retrieves relevant context, and drafts responses agents can review and send. For phone support, it provides real-time guidance in a sidebar while agents talk to customers. The same unified data layer powers both channels.

Understanding and optimizing the issue resolution curve.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

See how Bruviti unifies service data into a single interface that cuts handle time and improves resolution quality.

Schedule Demo