Your service network spans decades-old equipment and modern platforms — lock-in is not an option.

Industrial OEMs need customer service AI that integrates without vendor lock-in. API-first architectures using Python SDKs connect to existing CRM systems, train models on equipment-specific case data, and preserve data sovereignty while scaling agent productivity across global service networks.

Proprietary platforms trap your customer service data and workflows behind closed APIs. When case volumes span equipment with 10-30 year lifecycles, switching costs become prohibitive and your architecture choices outlast the vendor's commitment to your industry.

Contact center agents handle equipment-specific cases where failure modes vary by serial number range and run hours. When the AI misclassifies a CNC fault as a pump issue, you need the ability to inspect model behavior and retrain on corrected labels — not wait for vendor support.

Customer service AI that requires professional services for every CRM connection or knowledge base sync adds ongoing costs and delays. Your team needs standard REST APIs and Python SDKs to build integrations themselves without vendor dependency for each new data source.

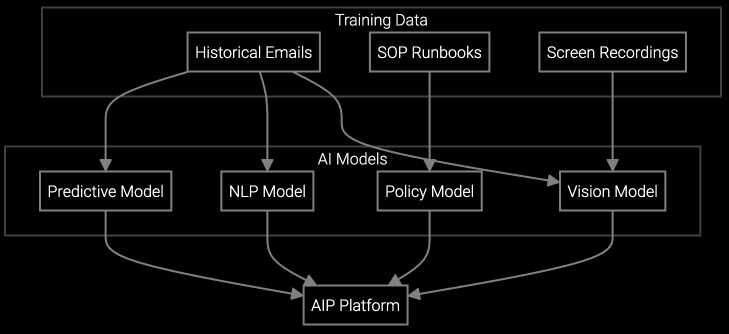

Industrial OEMs choosing customer service AI architectures face a build-versus-buy decision where neither extreme works. Building from scratch means training foundation models on massive compute — unrealistic for most engineering teams. Buying closed platforms means accepting proprietary APIs and losing control over equipment-specific model behavior.

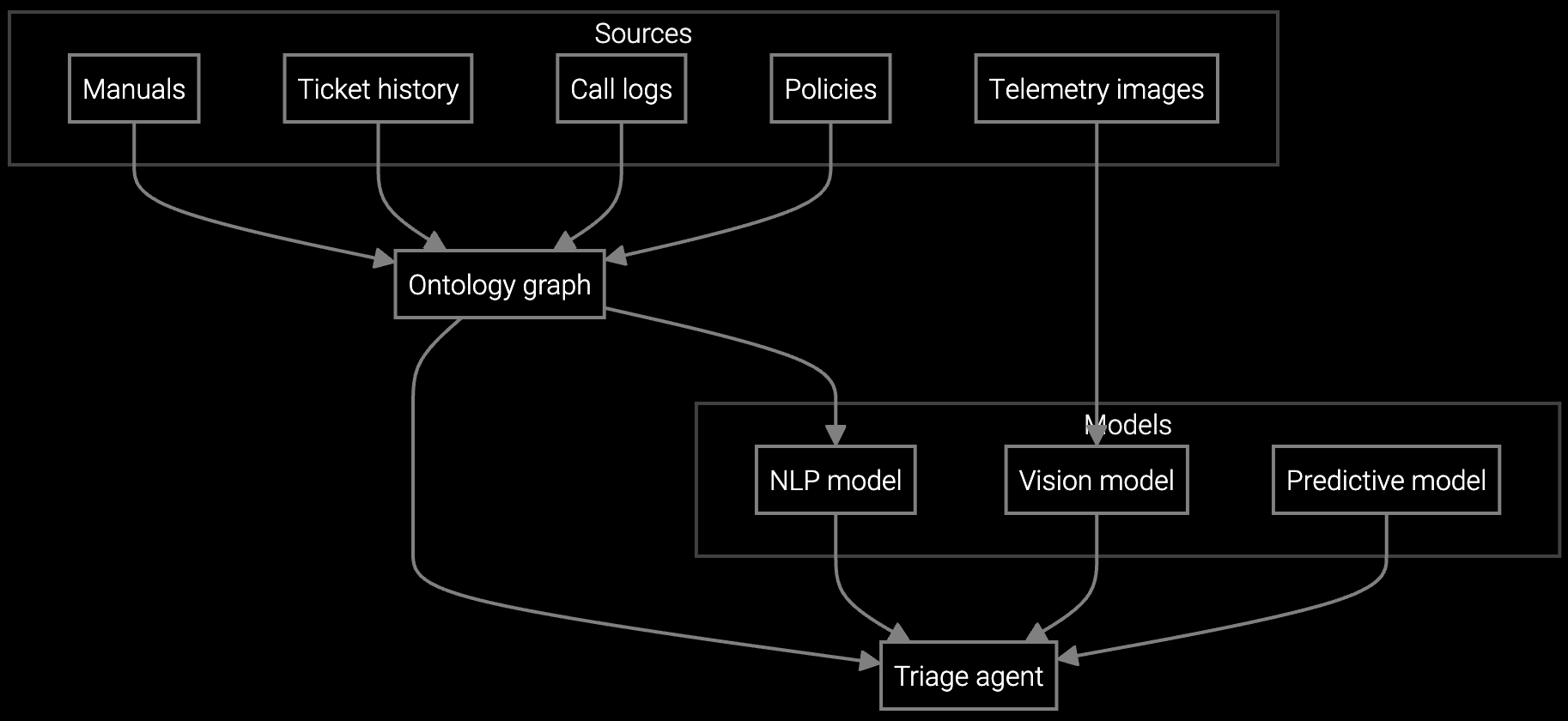

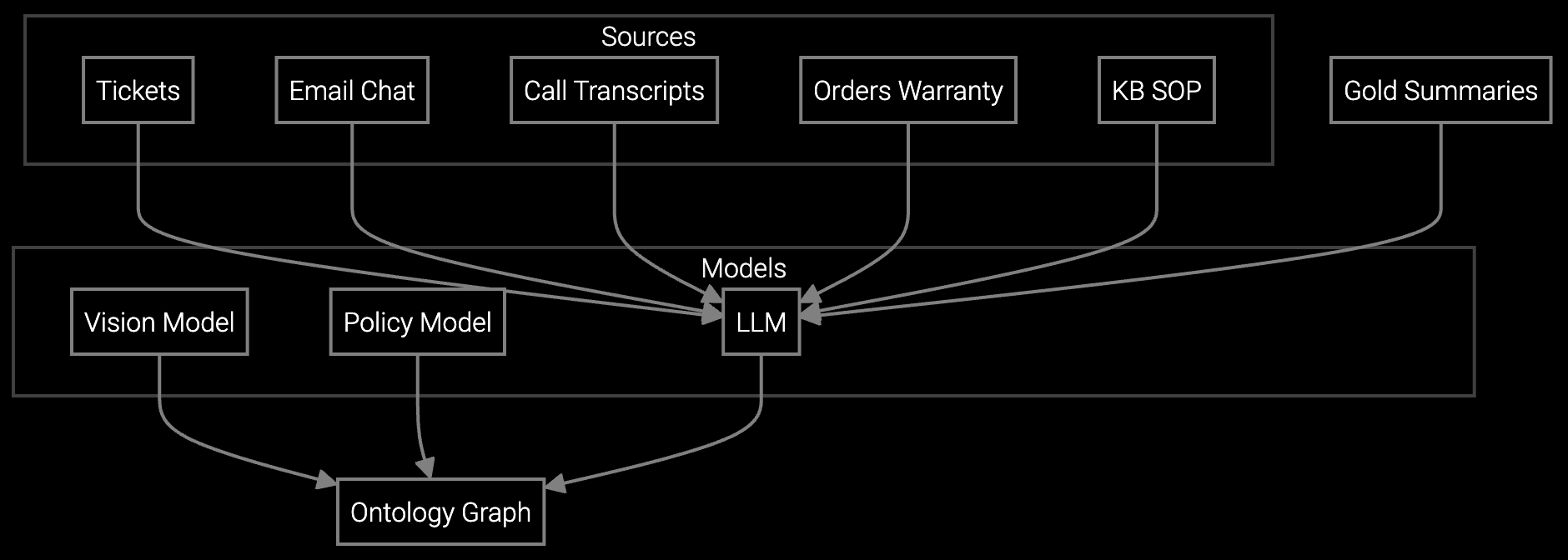

Bruviti's platform uses headless architecture with Python and TypeScript SDKs that integrate with existing CRM and ticketing systems through standard REST APIs. You train case classification models on historical service records specific to your equipment product lines, then deploy them where your agents work without replacing your CRM. Models ingest PLC codes, SCADA signals, and maintenance logs to route cases intelligently, and you retain full data sovereignty — your case history never leaves your infrastructure unless you explicitly configure external storage.

The architecture separates AI capabilities from the UI layer. Agents see inline suggestions in their existing tools while your team controls the underlying logic through code. When a model misroutes cases for a specific equipment serial number range, your engineers can inspect training data, adjust feature weights, and redeploy without vendor tickets. This matters for industrial equipment where failure modes are non-standard and documentation for legacy systems exists only in your service history.

Autonomous case classification for industrial equipment using PLC error codes and run hour patterns to route to specialized agent teams.

API-driven summaries from email threads, maintenance logs, and SCADA alerts give agents equipment history context without manual searching.

Python-scriptable email classification trained on your parts nomenclature and equipment terminology to draft responses using historical service cases.

Industrial OEM contact centers manage case histories spanning decades where equipment models from the 1990s still require parts and service support. Your CRM holds service records for CNC machines, pumps, and turbines that operators depend on for production uptime. Replacing that system to adopt AI would lose institutional knowledge and disrupt agent workflows trained on existing tools.

API-first architecture connects to legacy CRMs and custom ticketing systems through REST endpoints without migrating data. Models trained on SCADA error patterns and vibration signatures specific to your equipment product lines classify incoming cases and suggest responses inline within the agent's current interface. Your Python scripts control data flows — which telemetry sources feed the model, how cases route between agent teams, and where training logs persist for audit compliance.

Traditional platforms require agents to work inside the vendor's UI and store all data in the vendor's database. API-first architectures expose customer service AI capabilities through REST endpoints that integrate with your existing CRM, allowing you to build interfaces and control data storage yourself. This prevents lock-in and lets your team customize workflows using standard development tools like Python without vendor professional services.

Yes. The platform supports on-premises model training where your historical case data, PLC error codes, and maintenance logs never leave your infrastructure. You use Python SDKs to preprocess equipment telemetry, train classification models on your hardware, and deploy them to production — data sovereignty remains with your team throughout the lifecycle. External cloud training is optional, not required.

You inspect training data through the Python SDK to identify labeling errors or missing feature coverage for that serial range, retrain the model with corrected examples or additional telemetry signals, and redeploy it without vendor involvement. Open architecture means you control the feedback loop — when industrial equipment exhibits non-standard behavior, your engineers fix the model directly rather than filing support tickets.

Standard REST APIs connect to SAP, Oracle, and custom ERP systems using OAuth or API key authentication. Your team writes Python scripts that pull parts availability, service contract status, and equipment warranty data into the AI context so agents see accurate information during case resolution. No proprietary connectors or middleware required — if your ERP exposes an API, you can integrate it.

Python and TypeScript SDKs provide full access to model training, inference pipelines, and integration logic. REST APIs follow OpenAPI specifications for compatibility with any language. Your team can build custom workflows in the tools they already use — Flask, FastAPI, Node.js — without learning vendor-specific frameworks. Architecture follows cloud-native patterns with Docker support for deployment flexibility.

Understanding and optimizing the issue resolution curve.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Review API documentation, integration patterns, and deployment options for industrial equipment service AI.

Request Technical Review