Fab downtime costs $1M per hour. Your agents need answers in seconds, not months waiting for custom AI builds.

Buy proven models with API flexibility. Pre-trained AI on semiconductor support data deploys in weeks, not years. Customize workflows without vendor lock-in. Skip the build trap.

Building custom AI requires data scientists, ML engineers, and platform infrastructure. By the time your internal model goes live, your process recipes and equipment have changed.

Generic language models don't understand etch chamber drift, FOUP handling errors, or EUV metrology alerts. You spend months training models that vendors already have.

Internal builds often create tighter vendor lock-in than platforms. Proprietary training pipelines, custom integrations, and undocumented dependencies make switching harder than buying.

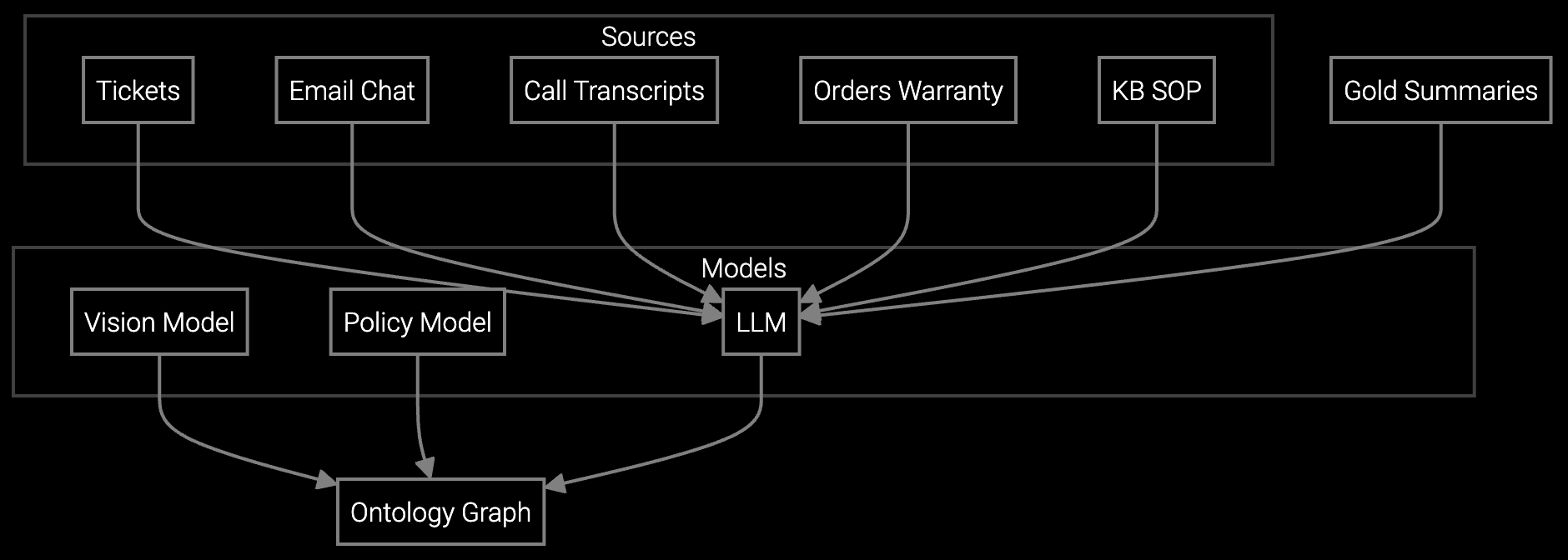

Bruviti combines pre-trained models with open APIs. Agents get instant answers for etch tool alarms, wafer handling errors, and recipe parameter questions without waiting for your data science team to spin up. The platform understands semiconductor terminology and failure modes from day one.

Start with proven workflows like case summarization and diagnostics triage. Customize routing logic, integrate with your MES and CRM systems, and extend models with proprietary process knowledge using Python SDKs. No lock-in means you own your training data and can export models if needed.

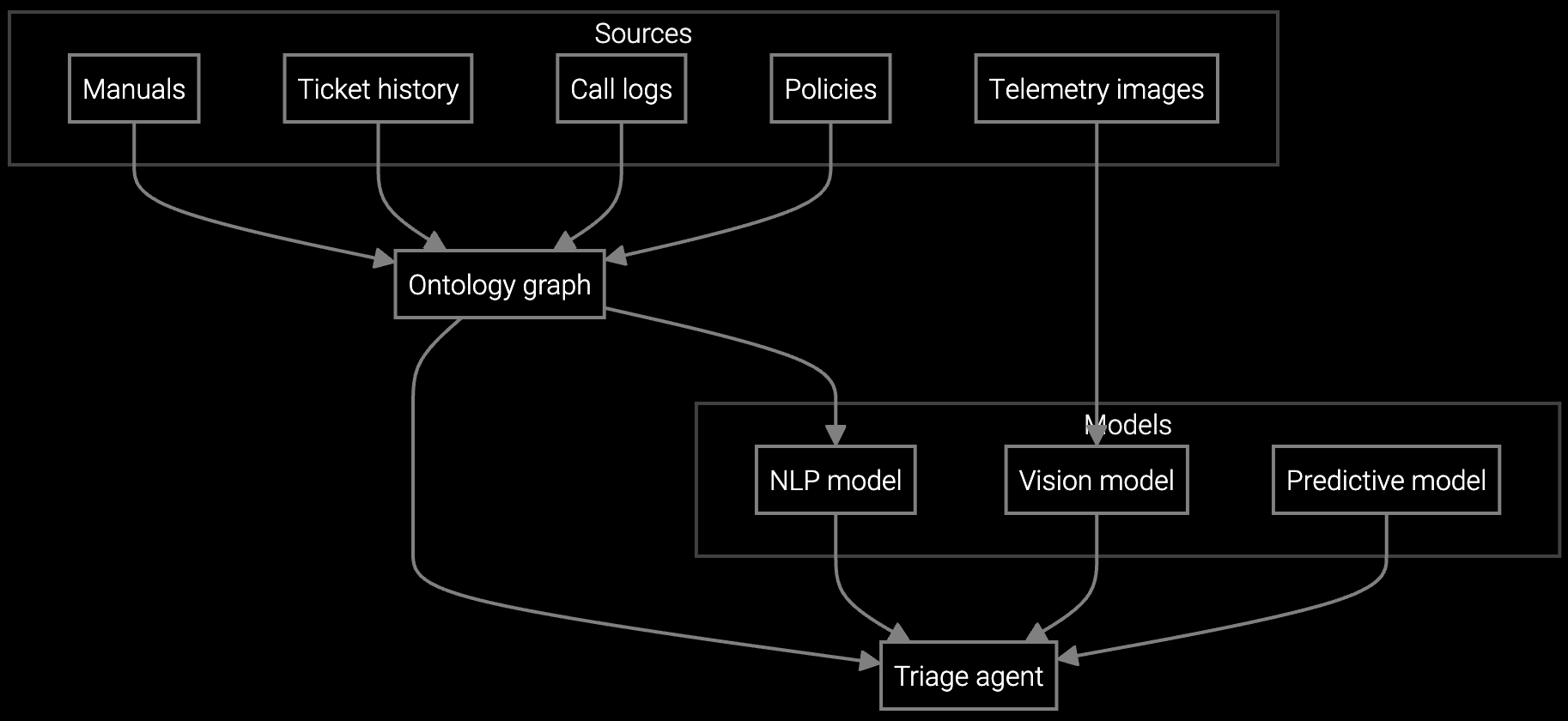

Automatically classify lithography tool errors, correlate sensor telemetry, and route cases to process engineers or field service based on failure severity and equipment utilization.

Generate instant summaries of multi-channel case histories including fab engineer emails, tool logs, and PM schedules so agents understand context without reading 50+ messages.

AI reads fab engineer emails about chamber performance drift, retrieves relevant process parameters from knowledge bases, and drafts responses with recommended PM intervals or replacement part numbers.

Lithography and etch tool support cases involve proprietary process recipes, chamber configurations, and metrology data that generic AI can't interpret. Building custom models requires years of historical case data, cleanroom terminology, and failure mode expertise that most data science teams lack.

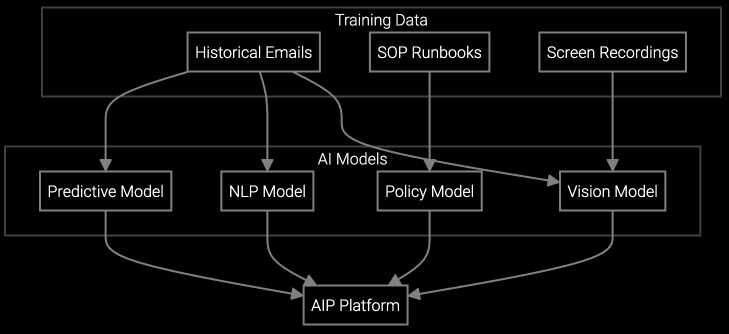

Pre-trained models understand wafer throughput impacts, recognize EUV versus DUV alert patterns, and correlate PM schedules with performance drift. Start with agent-assist for FOUP handling issues and recipe parameter questions, then extend to predictive consumable ordering and chamber component replacement forecasting as adoption grows.

Bruviti deploys in 4-6 weeks for initial use cases like case summarization and triage. Internal builds typically require 12-18 months to reach production, plus ongoing maintenance. Start with proven workflows, customize later as needed.

The platform supports fine-tuning on your proprietary data using secure model training pipelines. Start with generic semiconductor knowledge for common issues, then layer in fab-specific process parameters and equipment configurations through API-based customization.

Bruviti uses open APIs and allows model export. Your training data stays yours. Integrations connect through standard protocols, not proprietary connectors. If you ever switch platforms, you retain your knowledge base and historical training investments.

Yes. Most semiconductor OEMs start with one high-volume case type like etch tool alarms or FOUP handling errors. Prove ROI on handle time reduction, then expand to additional equipment types, more complex diagnostics, and predictive scenarios over 6-12 months.

API-first architecture connects to common MES platforms and CRM systems through REST APIs. Typical integrations take 2-4 weeks and pull tool status, case history, and knowledge base content into the agent interface without replacing existing systems.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

See how semiconductor OEMs deploy AI-powered agent assist in weeks, not years.

Schedule Demo