With fab customers demanding instant resolution on million-dollar downtime events, your service AI strategy determines competitive survival.

Semiconductor OEMs face a critical decision: build custom AI models requiring 18+ months and dedicated ML teams, buy inflexible vendor solutions with lock-in risk, or adopt API-first platforms that deliver pre-trained models with full customization rights. The optimal path balances speed to value with strategic control.

Custom AI development requires dedicated ML teams, clean training data, and infrastructure investment before delivering value. Most internal projects fail to reach production or deliver ROI below vendor benchmarks.

Black-box vendor solutions deliver fast initial results but create lock-in through proprietary data formats, limited customization, and integration constraints that compound over time as business needs evolve.

Competitors deploying AI-powered case resolution reduce their cost per contact by 40-60% while improving first contact resolution. Delayed decisions compound competitive disadvantage quarter over quarter.

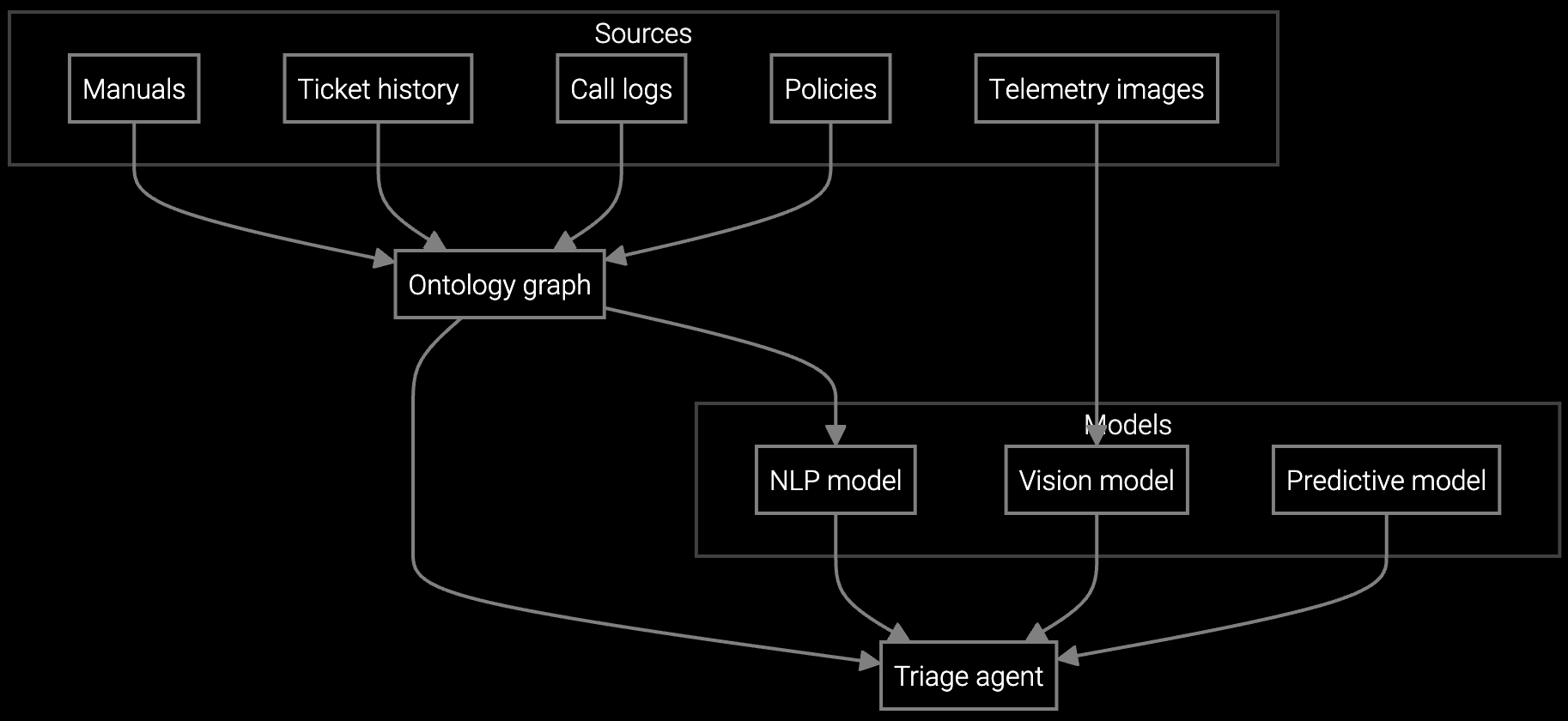

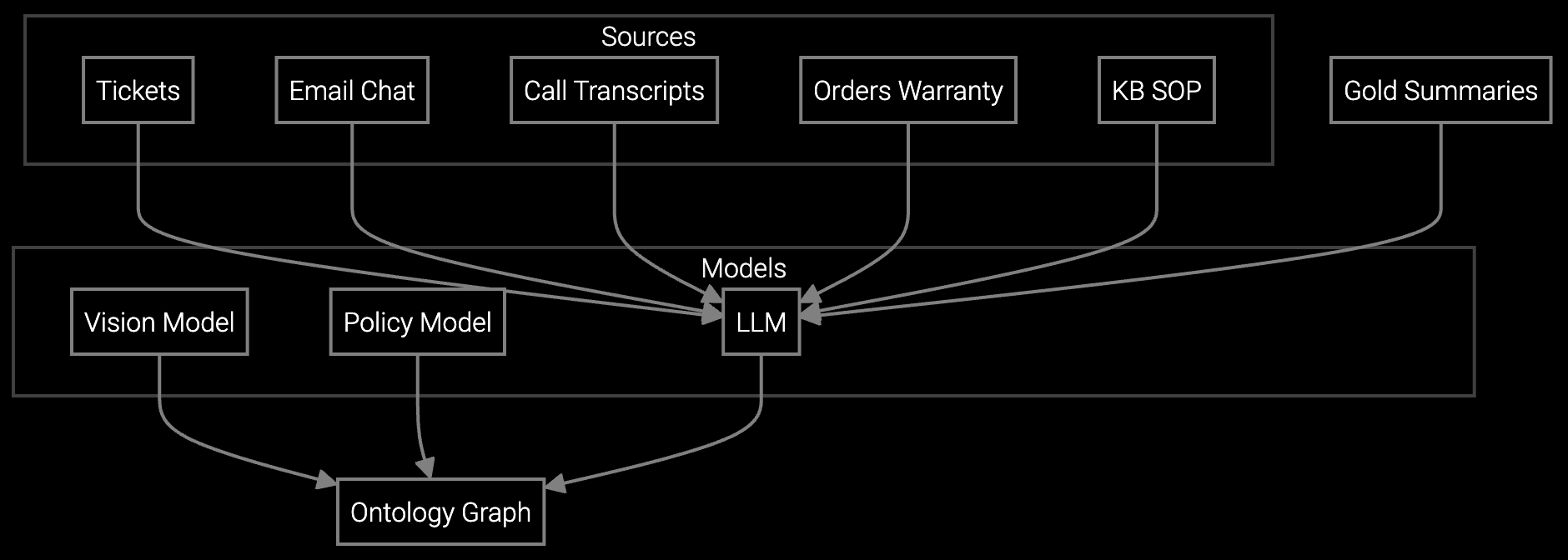

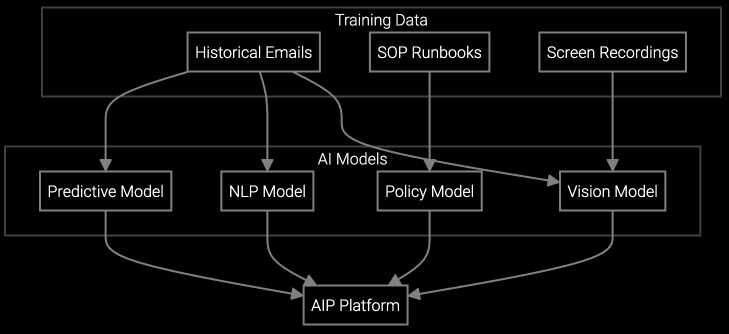

Bruviti's platform architecture resolves the build-versus-buy dilemma by delivering pre-trained models for immediate deployment alongside API-first extensibility for strategic control. Agents gain instant access to AI-powered knowledge retrieval, case summarization, and triage automation trained on 12 million historical service cases across semiconductor OEMs.

Simultaneously, your engineering teams access Python SDKs and REST APIs to train custom models on proprietary process data, integrate with existing CRM and ticketing systems, and build differentiated capabilities without vendor permission. This eliminates 18-month development timelines while preserving strategic flexibility as business needs evolve.

Autonomous case classification analyzes lithography tool symptoms, correlates chamber telemetry, and routes critical fab downtime issues to specialized teams with diagnostic context reducing mean time to resolution.

Instantly generates case summaries from multi-channel fab customer communications including emails, chat logs, and call transcripts so agents understand equipment history without reading hundreds of interactions.

AI automatically reads, classifies, and routes fab customer emails about etch tool performance issues or metrology questions, drafting responses using historical case data and technical knowledge bases for consistent resolution guidance.

Fab customers operate under extreme uptime pressure where lithography tool downtime costs exceed $1 million per hour. Your contact center handles urgent technical escalations about chamber component failures, recipe parameter drift, and yield correlation issues requiring instant access to decades of process engineering knowledge.

Traditional service models fail when agents lack context about specific tool configurations, historical failure patterns, or customer-specific process parameters. The strategic question is not whether to deploy AI but which deployment model preserves competitive differentiation while delivering measurable ROI within two quarters.

Building requires dedicated ML engineers ($200K-$400K annually each), GPU infrastructure ($50K-$150K), data cleaning resources, and 18-24 months before production deployment. Most internal projects fail to reach production or deliver ROI below vendor benchmarks. Platform costs are subscription-based with predictable monthly fees and immediate value delivery.

Evaluate data portability guarantees, model ownership rights, and API access terms. Bruviti provides full model export capabilities, open API architecture, and customer data ownership ensuring you can migrate or extend capabilities without vendor permission or switching costs.

Pre-trained platforms deliver measurable improvements in first contact resolution and average handle time within 30-60 days of deployment. Custom-built solutions require 18-24 months minimum. Strategic advantage accrues to organizations deploying quickly then iterating based on production data rather than perfecting solutions before launch.

Leading OEMs deploy AI for autonomous case triage, knowledge retrieval during fab escalations, and predictive routing based on equipment type and failure mode. This reduces cost per contact 45-60% while improving first contact resolution rates from 65% to 85%+. Laggards face compounding competitive disadvantage as AI leaders reinvest margin gains into service capacity and innovation.

Platforms minimize technical requirements but success depends on clean data access, change management for agent adoption, and executive commitment to measure and iterate. Organizations with existing CRM integrations and structured case data deploy fastest. Those lacking data infrastructure should prioritize that foundation before evaluating AI solutions.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

Schedule a strategy session with Bruviti's executive team to map your path from decision to deployment.

Schedule Strategy Session