Equipment downtime costs manufacturers thousands per hour—getting predictive parts management running fast matters.

Deploy predictive inventory by connecting equipment telemetry feeds to demand forecasting models, integrating with your ERP system, and configuring stockout alerts—typically complete in 2-4 weeks with minimal workflow disruption.

Connecting decades of legacy systems with scattered parts data across multiple warehouses creates integration bottlenecks. You need a system that works with what you have, not one that forces a complete infrastructure overhaul.

Rolling out new inventory tools while maintaining daily operations means any system that changes how your team works will face resistance. You need deployment that fits into existing processes without retraining everyone.

Forecasting demand requires historical failure data, but older equipment models have incomplete service records. Without sufficient training data, predictions remain unreliable and you're back to manual ordering.

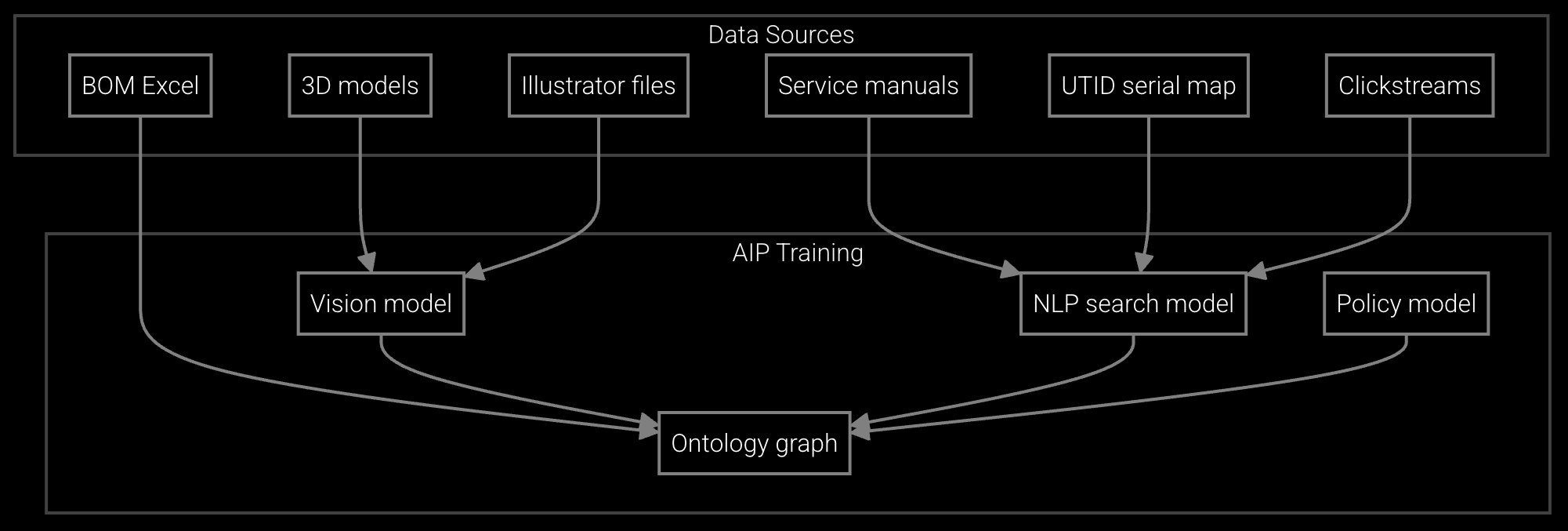

Bruviti's platform deploys in phases starting with a single product line or warehouse location. Connect your existing inventory system through REST APIs or direct database connectors—no need to replace your ERP. The platform ingests historical parts orders, equipment telemetry, and service records to build demand forecasting models specific to your installed base.

Start with automated stockout alerts for critical components. Your team sees instant notifications when inventory levels drop below predicted demand thresholds, all within the same ordering interface they already use. As confidence builds, expand to automated reorder suggestions and substitute parts matching across your full catalog.

Predict parts consumption for industrial machinery based on equipment age, run hours, and seasonal maintenance cycles across distributed warehouse locations.

Optimize stock levels by forecasting demand windows for critical components, reducing both stockouts and excess inventory carrying costs.

Automatically maintain accurate parts catalogs by cross-referencing engineering specs, service bulletins, and legacy equipment documentation.

Industrial OEMs face unique challenges with 10-30 year equipment lifecycles and geographically distributed service operations. Start deployment with high-value machinery categories where parts obsolescence hits hardest—CNC machines, turbines, or automation systems with aging installed bases.

Connect condition monitoring feeds from PLCs and SCADA systems to enrich demand forecasts with real-time equipment health data. This allows the platform to predict parts needs based not just on age, but on actual run hours, vibration patterns, and operating conditions specific to each customer site.

Most ERP integrations complete in 1-2 weeks using REST APIs or database connectors. SAP and Oracle systems typically connect faster due to pre-built adapters. The platform reads inventory levels and order history without requiring changes to your existing workflows.

The platform starts with whatever data exists and improves forecasts as new orders come in. For equipment with sparse records, it uses failure patterns from similar models and adjusts predictions based on equipment age and usage intensity rather than requiring complete service histories.

Yes. The system runs parallel to existing processes during the pilot phase. Your team continues using current ordering workflows while the platform generates forecasts in the background. Alerts and recommendations appear within your existing interface, requiring no new tools to learn.

The platform identifies substitute parts by analyzing technical specifications, dimensional compatibility, and historical replacement patterns. When original parts reach end-of-life, it automatically suggests compatible alternatives from current inventory or approved suppliers.

You need at least 6-12 months of parts order history and basic equipment install dates. Enhanced forecasts come from adding telemetry feeds, but the platform produces useful predictions even with just transactional data and equipment age information.

SPM systems optimize supply response but miss demand signals outside their inputs. An AI operating layer makes the full picture visible and actionable.

Advanced techniques for accurate parts forecasting.

AI-driven spare parts optimization for field service.

See how Bruviti deploys in your environment with a guided technical walkthrough.

Schedule Setup Call