Your equipment's running 24/7, and your team can't afford downtime during a system rollout.

Deploy asset tracking in phases: Start with high-value equipment using existing serial number scans, connect to your SCADA/PLC feeds for automatic updates, and validate accuracy through daily operational checks rather than manual audits.

Your legacy systems have gaps where serial numbers were never entered or were recorded incorrectly. You can't track what you can't identify, and fixing thousands of records manually isn't realistic during normal operations.

Equipment configurations change in the field—firmware updates, component swaps, retrofits—but your asset database doesn't reflect these changes. When your records don't match what's actually deployed, you lose visibility into lifecycle status.

Verifying asset data accuracy requires manual audits that pull staff off their core work. Without automated validation tied to your operational systems, data quality degrades over time and you're never confident in what you're looking at.

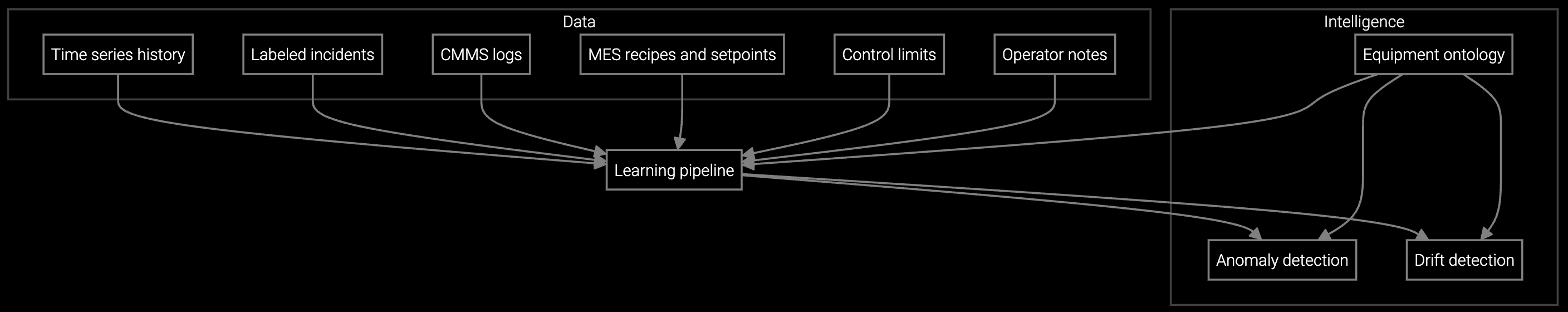

The platform deploys without requiring a maintenance window. You start by connecting to your existing SCADA or PLC systems, which are already collecting telemetry from deployed equipment. The platform reads these data streams and automatically identifies assets, matching them to your existing records where serial numbers exist and flagging gaps where they don't.

Instead of halting operations to conduct a manual inventory, you validate data during routine checks. When service staff access an asset record for scheduled maintenance or troubleshooting, the platform prompts them to confirm or update serial numbers, firmware versions, and configuration details. This validation happens in context, as part of existing workflows, not as a separate data cleanup project. Over time, your asset database becomes accurate through operational use rather than dedicated audit cycles.

Automatically identify equipment anomalies by analyzing IoT telemetry streams from CNC machines, pumps, and compressors—catching issues before they become failures.

Estimate when critical components will fail based on run hours and usage patterns, enabling planned maintenance during scheduled downtime.

Continuously monitor vibration, temperature, and pressure sensors, alerting your team the moment readings deviate from normal operating ranges.

Industrial equipment manufacturers face unique deployment challenges: equipment lifecycles span decades, assets are geographically distributed, and production schedules don't accommodate extended downtime for system migrations. Your deployed base includes CNC machines running 20-hour shifts, compressors in remote locations, and legacy turbines still generating value after 25 years.

The platform handles this by starting with your highest-value, most-monitored assets—the equipment already connected to SCADA or condition monitoring systems. These assets provide the richest telemetry and the clearest ROI. Once the platform proves accuracy and operational value on this subset, you expand coverage to less-instrumented equipment, using barcode scans during scheduled maintenance to capture serial numbers and configuration details incrementally.

No. The platform connects to SCADA and PLC systems via read-only data feeds that don't require interrupting operations or modifying control logic. Your equipment continues running while the platform begins ingesting telemetry in the background.

Most deployments reach 90% asset coverage within 90 days. The platform auto-populates data from telemetry feeds immediately, then fills gaps through workflow-embedded prompts during routine maintenance activities. You don't need to wait for 100% accuracy to start using the system—value builds incrementally.

For legacy assets without telemetry, the platform supports manual serial number entry via mobile barcode scanning during scheduled maintenance. Service staff scan asset tags, and the platform links these to existing records or creates new ones. This captures configuration and lifecycle data over time without requiring sensor retrofits.

Yes. Most customers start with a single high-value product line—such as CNC machines or industrial pumps—to validate accuracy and operational impact. Once the pilot proves ROI, the same integration approach scales to other equipment types without re-engineering data connections.

The platform detects configuration drift automatically by comparing current telemetry signatures to known baselines. When firmware versions, component swaps, or retrofits occur, the platform flags these changes and prompts service staff to confirm details during the next operational interaction, keeping records synchronized with reality.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti integrates with your existing SCADA and PLC systems to build accurate asset records through operational workflows.

Schedule Demo