When fab downtime costs $1M+ per hour, support agents need instant answers—not 10 minutes searching across CRM, ERP, and PDF manuals.

AI automates case triage, parts lookup, and knowledge retrieval for semiconductor equipment support agents. Eliminates swivel-chair workflows across CRM, ERP, and service manuals while maintaining complete SLA visibility and audit trails for fab-critical support operations.

Agents toggle between CRM, ERP, knowledge base, and equipment telemetry portals to answer a single case. Each tool switch adds friction, delays resolution, and increases handle time for fab-critical support requests.

Finding the right troubleshooting procedure or part number requires searching 500+ page manuals and tribal knowledge emails. New agents take months to learn where information lives across fragmented repositories.

Agents manually read symptoms, classify urgency, assign priority codes, and route cases to the right queue. This repetitive work consumes time that could be spent solving actual problems.

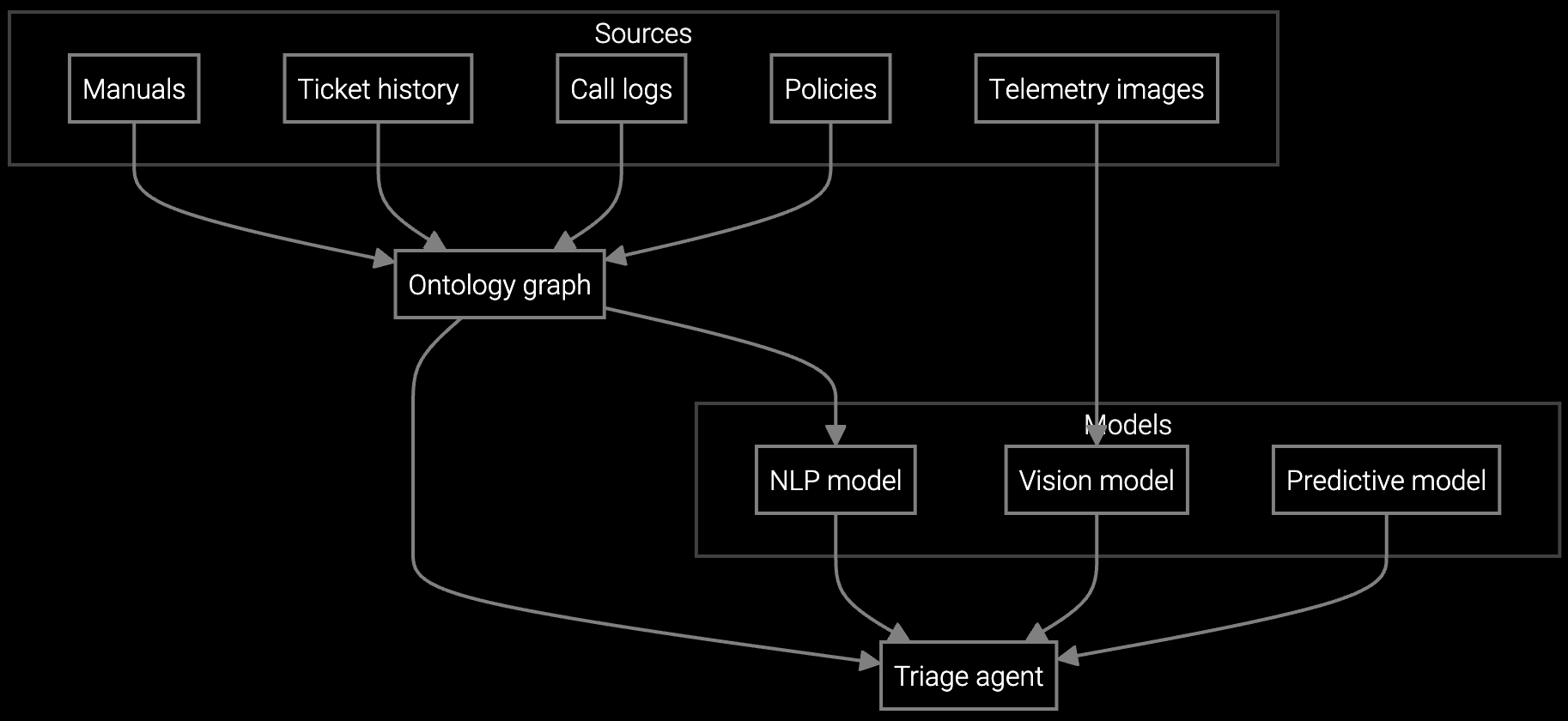

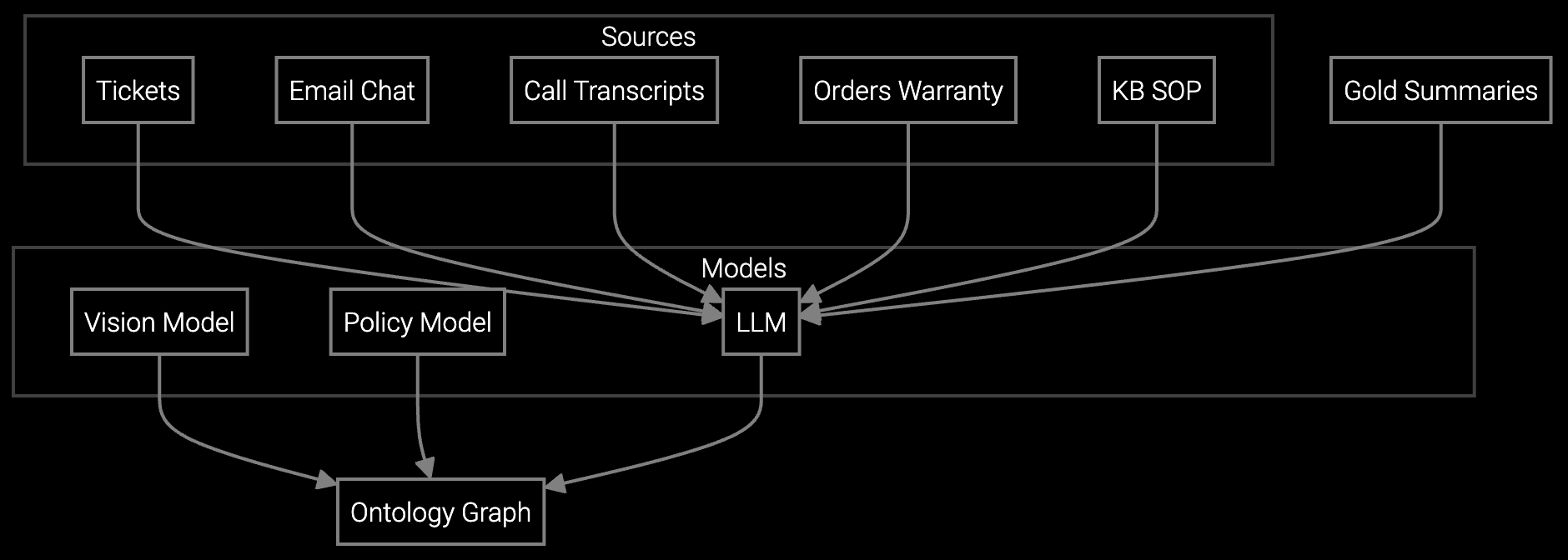

Bruviti consolidates the entire support workflow into one interface. When a case arrives, AI instantly classifies the issue, retrieves relevant troubleshooting steps from equipment manuals, surfaces similar past cases, and presents chamber part numbers if replacement is needed. Agents see equipment history, telemetry context, and recommended next steps without leaving their screen.

The platform auto-populates case notes, suggests responses based on resolution patterns, and routes escalations to the right specialists. Agents validate AI recommendations rather than hunting through systems. What previously required 8-12 tool switches now happens in a single view with all context pre-assembled.

Automatically classify lithography tool alarms, correlate with telemetry patterns, and route to etch specialists or PM scheduling based on symptom signatures.

Generate instant summaries from multi-thread email chains between fab engineers and OEM support, highlighting recipe changes and chamber part swaps.

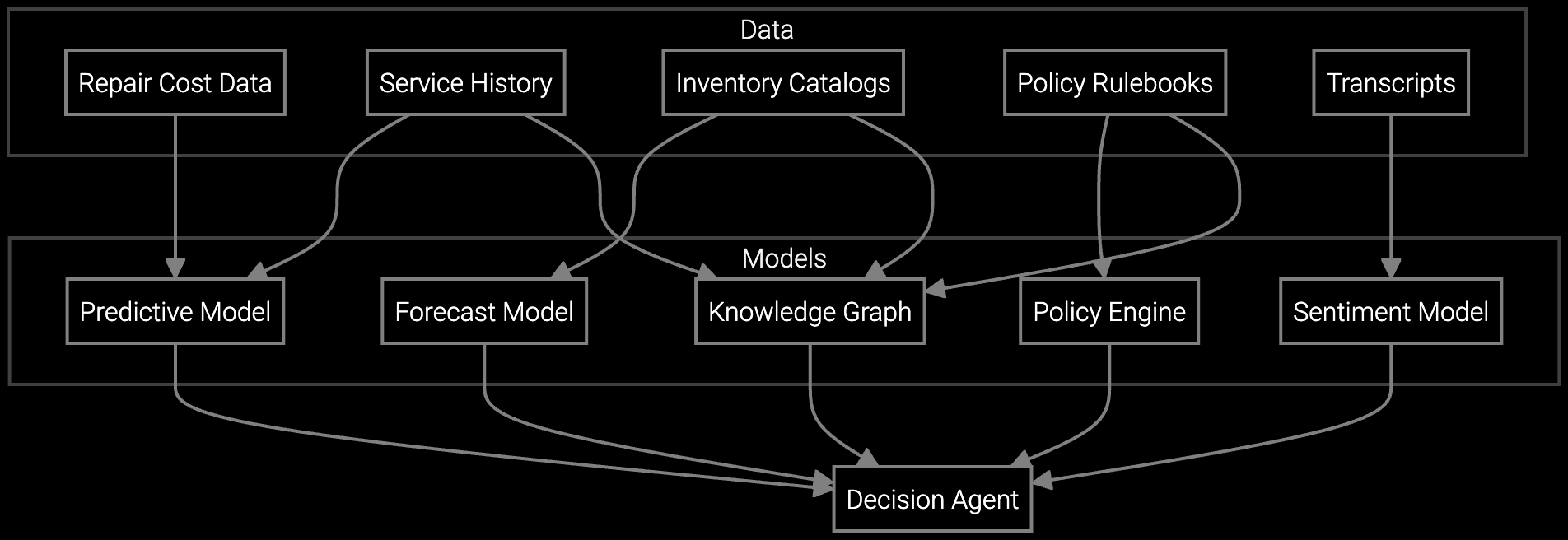

Compare chamber kit refurbishment cost versus new part pricing based on equipment age, utilization hours, and current fab production schedules.

Semiconductor fabs operate 24/7 with wafer throughput measured in minutes. When an etch tool throws an alarm at 2 AM, support agents must diagnose whether it's a chamber seasoning issue, a recipe parameter drift, or a gas flow controller failure—all while the fab loses $50K per hour of downtime.

AI workflow automation pulls equipment telemetry, cross-references similar alarms from other fabs, and suggests whether to dispatch a field engineer or guide the fab tech through a remote fix. Agents see FOUP handling history, recent PM records, and consumables usage in one view, eliminating the delays from logging into separate OEE tracking and spare parts systems.

The platform learns from your service history and equipment manuals to understand tool-specific nomenclature. When trained on past cases involving EUV versus DUV lithography systems, it distinguishes between scanner generations and suggests troubleshooting steps matched to the exact tool model and software version.

Agents review all AI-suggested classifications before confirming the routing decision. The system flags confidence scores—anything below 85% goes to human verification. Over time, corrections train the model to improve accuracy on edge cases specific to your equipment portfolio and fab customer base.

Yes. The platform integrates with telemetry streams via API to surface recent alarms, process parameter trends, and utilization hours directly in the case view. Agents see whether the tool is currently running production or idle, eliminating the need to call the fab for status updates.

The interface presents AI outputs as recommendations with cited sources—showing which manual section or past case informed the suggestion. Agents approve actions rather than having the system execute automatically. This keeps humans accountable while removing the busywork of hunting for information.

No. Automation removes repetitive classification work, freeing senior agents to focus on complex escalations that require judgment. Junior agents handle more routine cases independently because AI surfaces the right context, reducing the coaching burden on senior staff while improving overall team throughput.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

See how semiconductor equipment OEMs are cutting agent handle time by 65% with single-screen AI workflows.

Schedule Demo