When fab customers demand sub-hour response times and agents face 50+ knowledge sources, manual workflows create the bottlenecks you can't afford.

Automating customer service workflows in semiconductor manufacturing means orchestrating case triage, knowledge retrieval, and escalation through AI agents that handle routine inquiries end-to-end while routing complex issues to specialized support teams with full diagnostic context and recommended solutions.

Agents toggle between ticketing systems, knowledge bases, product manuals, and process documentation to answer a single inquiry. Every context switch adds delay and error risk.

Human classification of incoming cases creates bottlenecks as agents read symptoms, guess severity, and forward to the wrong team, triggering reassignment loops.

Escalations from Tier 1 to specialized engineers arrive without diagnostic history, forcing the next agent to re-interview the customer and duplicate troubleshooting steps.

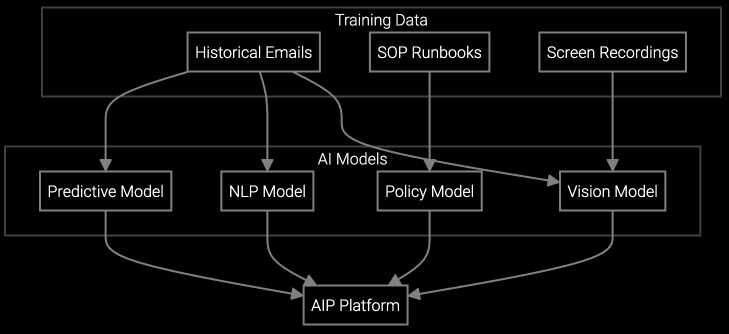

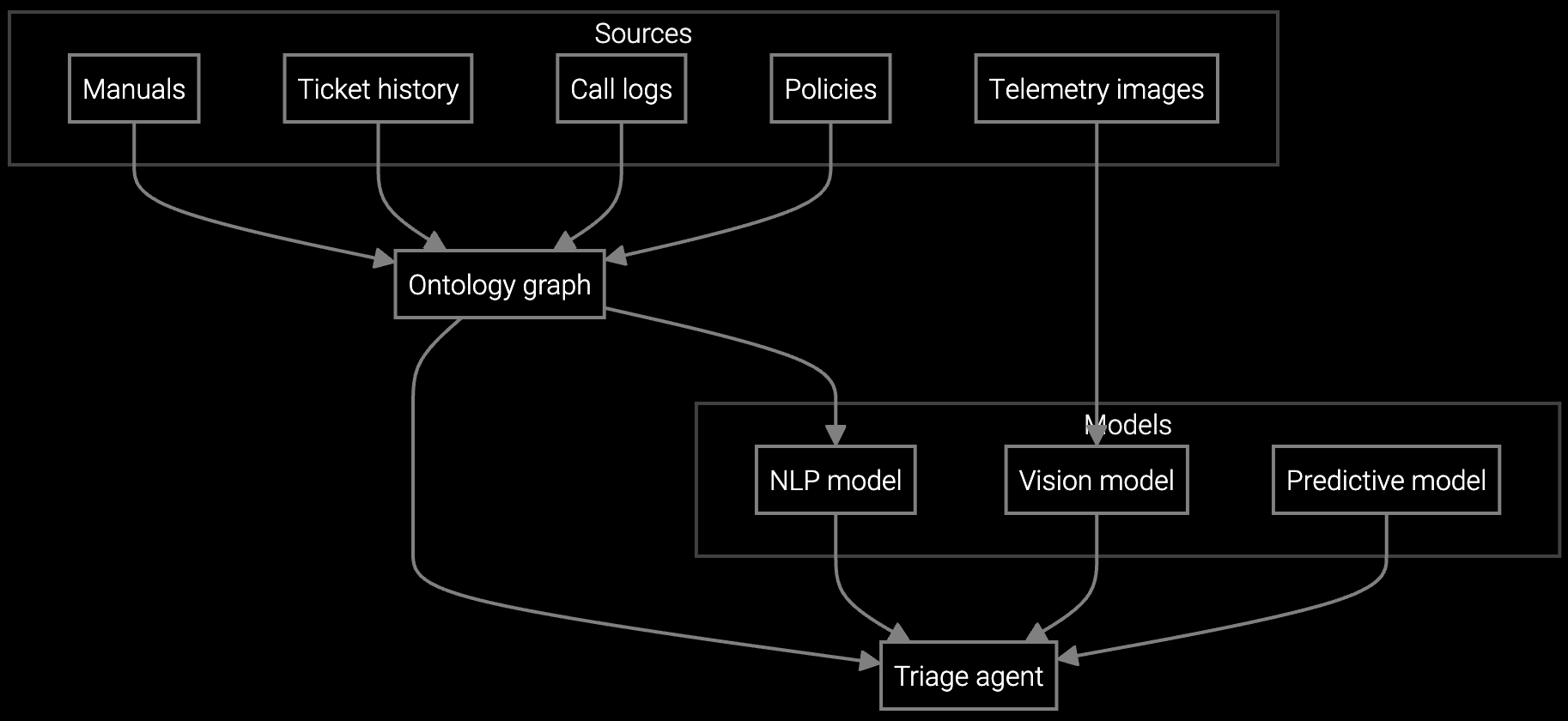

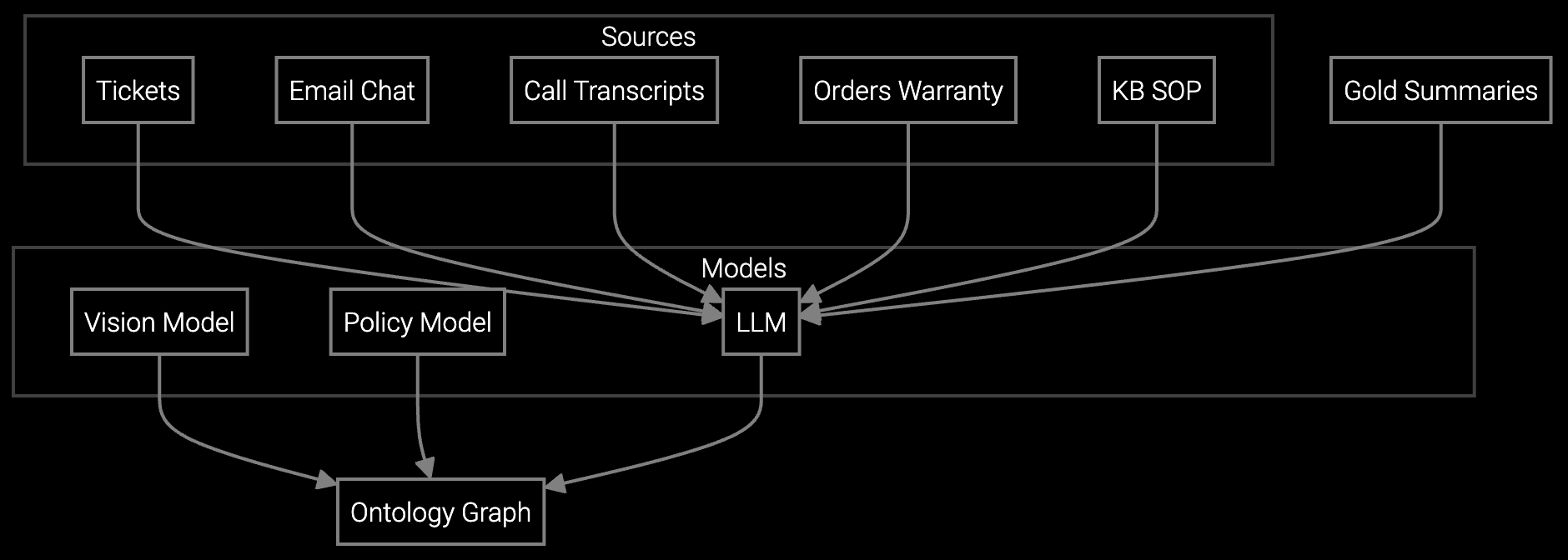

Bruviti's platform automates the entire customer service workflow from case creation through resolution. AI agents intake inquiries via email or web form, classify by failure mode and urgency using telemetry correlations, retrieve relevant technical documentation from manuals and past cases, and either auto-resolve routine requests or escalate complex issues with a pre-populated diagnostic brief.

For semiconductor OEMs supporting fab customers, this means eliminating the multi-system navigation that inflates Average Handle Time. The platform unifies case history, equipment configuration, process recipe context, and parts inventory status into a single resolution interface. Human agents review AI-prepared recommendations rather than starting from scratch, cutting decision time while preserving accountability for high-stakes resolutions that impact wafer throughput.

AI reads incoming emails from fab engineers, extracts equipment IDs and error codes, classifies urgency, and drafts responses using technical documentation and past case resolutions.

Autonomous classification analyzes symptom descriptions, correlates with equipment telemetry patterns, and routes cases to process engineers or field service with recommended diagnostic steps.

Instantly generates case summaries from multi-channel interactions so agents understand equipment history, past failure modes, and previous resolutions without reading dozens of notes.

Semiconductor equipment OEMs face unique workflow complexity because fab customers operate in an environment where every minute of unplanned downtime costs tens of thousands of dollars. A single lithography tool failure can halt an entire production line processing wafers worth millions. Customer service workflows must therefore prioritize speed and precision—agents need instant access to equipment configuration, process recipe parameters, and chamber component history to diagnose issues without delays.

Traditional ticketing workflows break under this pressure. When a fab engineer submits a case about unexpected etch rate variation, manual classification forces the agent to read logs, guess which subsystem is failing, and forward the case through multiple routing steps before it reaches a process specialist. Automated workflow orchestration eliminates these handoffs by analyzing telemetry correlations, matching symptom patterns to known failure modes, and delivering a pre-qualified escalation package directly to the right expert within minutes of case creation.

Automated workflows handle routine inquiries end-to-end without human intervention, allowing agents to focus on high-value escalations. For semiconductor OEMs, this typically reduces cost per contact by 40-50% as AI executes knowledge retrieval, case classification, and response drafting workflows that previously consumed Tier 1 agent time. The platform also eliminates reassignment loops by routing cases to the correct specialist on the first attempt.

The platform correlates case symptoms with equipment telemetry patterns and historical failure modes to classify urgency and assign routing priority. For semiconductor equipment, this means analyzing error codes, chamber pressure deviations, and recipe parameter drift to distinguish between routine calibration requests and critical failures that threaten wafer throughput. Human agents retain override authority for edge cases, but AI-driven classification accuracy typically exceeds 92% after training on historical case data.

Track Average Handle Time reduction for cases handled by AI versus manual workflows, calculate labor cost savings from autonomous Tier 1 resolution, and measure escalation accuracy improvements that eliminate reassignment waste. For semiconductor OEMs, also monitor First Contact Resolution rates for equipment configuration and parts availability inquiries, as these directly impact fab customer satisfaction scores and contract renewal rates.

Yes, the platform connects via API to existing systems like Salesforce Service Cloud, ServiceNow, and industry-specific CMMS platforms. For semiconductor equipment OEMs, this means AI agents can pull equipment configuration from ERP systems, retrieve PM schedules from CMMS, check parts inventory in real-time, and write case notes back to the ticketing system without requiring agents to switch contexts or manually copy data between systems.

Automate high-volume, low-complexity workflows like parts lookups, PM schedule confirmations, and case status updates. Keep human agents responsible for complex diagnostic escalations, contract negotiations, and any decision involving warranty claims or liability. For semiconductor OEMs, this boundary typically means AI handles 60-70% of incoming case volume while agents focus on process recipe troubleshooting and field service coordination that requires engineering judgment.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

Discover how semiconductor equipment OEMs are cutting Average Handle Time by 47% with AI-orchestrated case workflows.

Schedule Demo