When fab downtime costs $1M+ per hour, agent workflow delays compound into production losses—automation must match precision requirements.

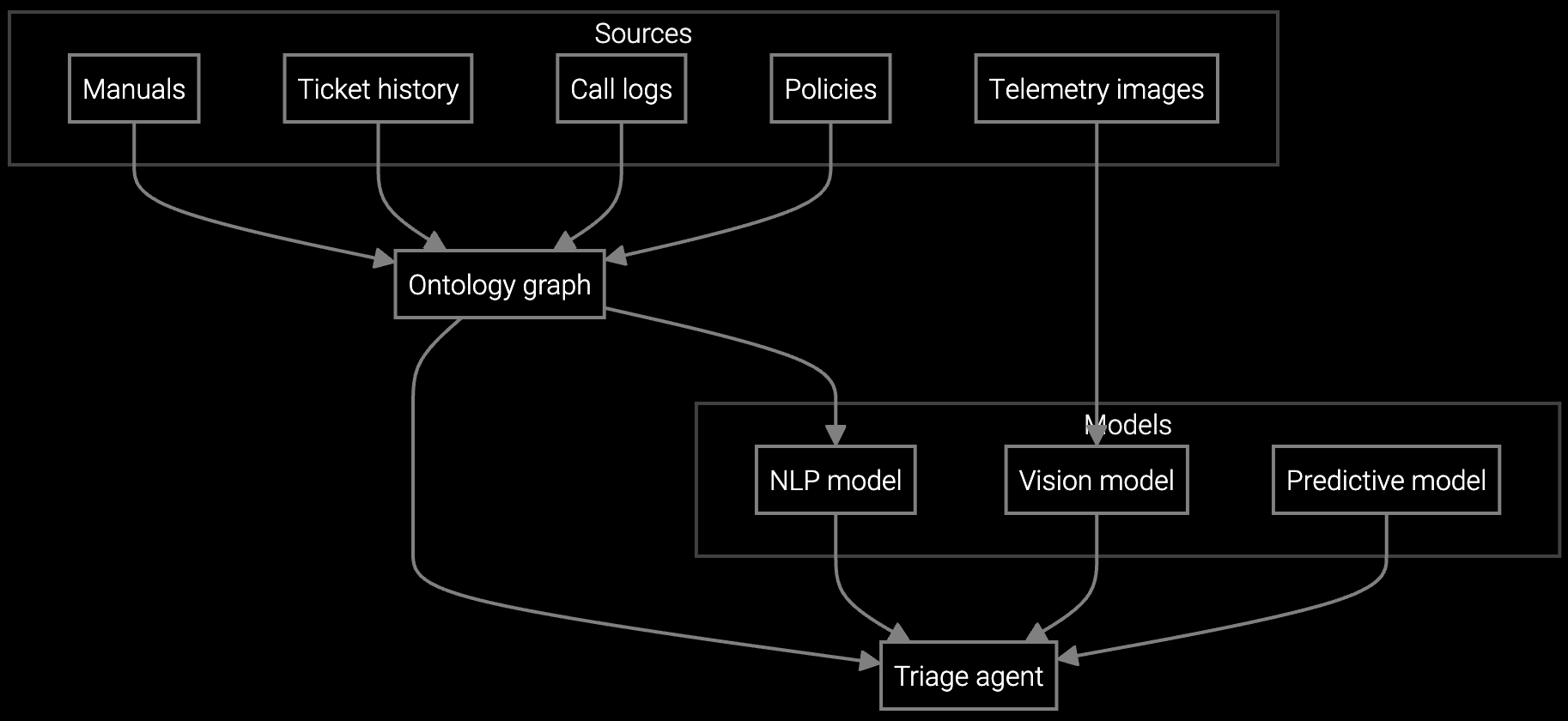

Semiconductor equipment OEMs automate agent workflows by connecting telemetry APIs to case management systems, enabling AI to classify failures, retrieve equipment history, and route issues without manual triage—reducing handle time while maintaining context across fabrication environments.

Agents spend minutes searching multiple knowledge bases to categorize lithography system alarms, etch chamber recipe drift, or metrology tool calibration issues. Each lookup delays response while fab equipment waits.

Customer service systems don't automatically surface FOUP handling history, PM schedules, or process recipe changes—agents manually piece together context from ERP, telemetry platforms, and service logs.

Without automated severity scoring, routine consumable requests get escalated while critical OEE-impacting failures sit in general queues. Inconsistent routing wastes engineering time and extends resolution cycles.

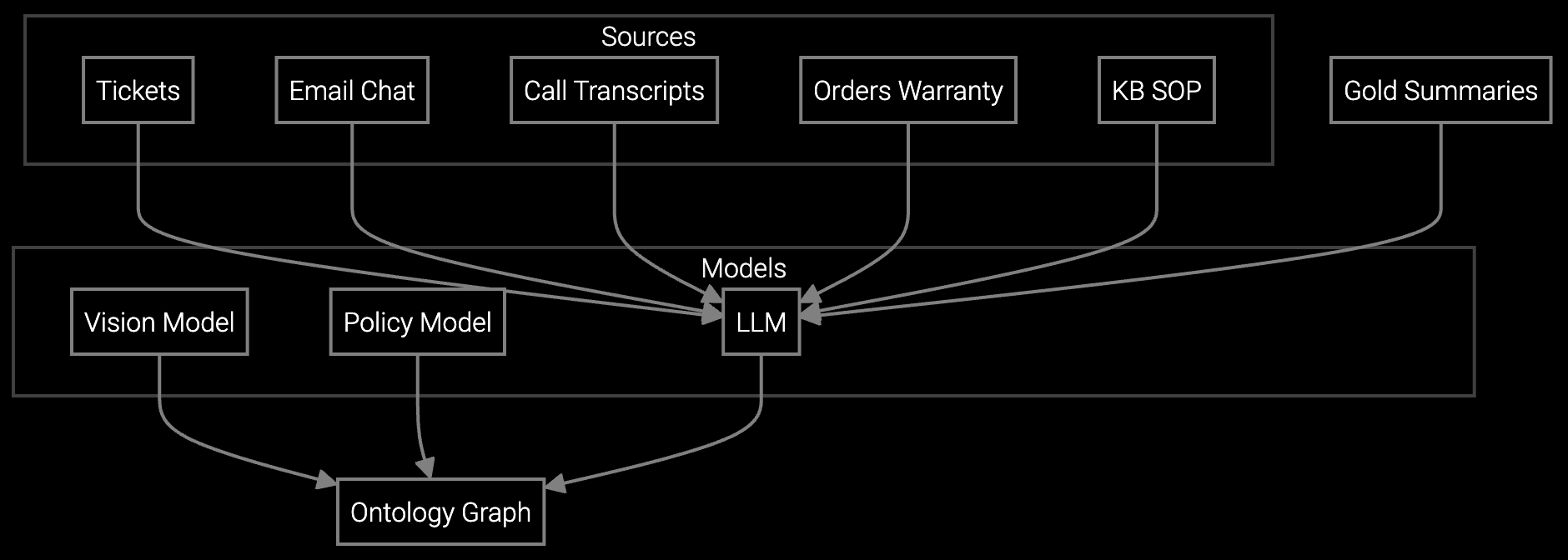

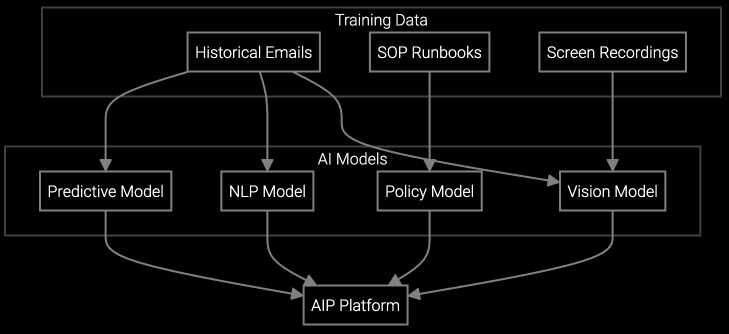

Bruviti's headless architecture exposes RESTful APIs that integrate with existing CRM and ticketing systems without replacing your stack. Python SDKs let developers define custom routing logic, connect telemetry streams from tool sensors, and trigger automated workflows based on equipment state—all using standard languages and event-driven patterns you already understand.

The platform ingests process telemetry, historical case data, and equipment maintenance records to train classification models specific to your product line. When a case arrives, the API analyzes symptoms, correlates with sensor data, retrieves relevant service history, and returns structured recommendations—agents see context-rich resolution paths instead of empty forms. You control which workflows run autonomously and which require human review, configuring thresholds via API parameters rather than vendor-controlled dashboards.

Autonomous case classification correlates lithography alarm codes with telemetry patterns, routing EUV source issues to optics specialists and chamber contamination cases to process engineers without agent intervention.

Instantly generates case summaries from fab engineer emails, tool logs, and preventive maintenance schedules—agents see complete equipment context without switching between ERP, telemetry dashboards, and ticketing systems.

AI reads incoming consumable reorder requests, verifies FOUP serial numbers against install base records, and drafts responses with part numbers and lead times—agents approve rather than research from scratch.

Semiconductor tool environments generate dense telemetry streams—chamber pressure logs, recipe parameter drift, wafer throughput metrics, PM cycle counters. Automated workflows must correlate this data with case symptoms in real time, distinguishing routine consumable wear from process excursions that cascade through multiple tools.

API-driven automation connects to existing telemetry platforms, pulling sensor data alongside case descriptions. When a fab engineer reports overlay errors on a lithography system, the workflow retrieves recent recipe changes, reticle inspection logs, and stage calibration history—agents receive diagnostic context before the first customer callback, reducing multi-day ping-pong exchanges to same-shift resolutions.

At minimum, expose case intake endpoints that accept symptom descriptions and equipment identifiers, plus telemetry query APIs that return recent sensor data for specific tool serial numbers. Optional escalation APIs let you define custom routing logic based on severity scores returned by classification models. The platform provides Python SDKs with example integration code for common CRM and telemetry systems.

Classification models train on your historical case data, learning the relationship between recipe parameters and failure modes specific to your tool designs. When a case references a custom etch recipe or proprietary litho process, the workflow retrieves the relevant parameter set from your telemetry platform and correlates it with similar past cases—agents see recipe-aware diagnostics rather than generic troubleshooting steps.

Yes. API parameters let you set confidence thresholds for each automation stage. For example, you might auto-classify routine consumable requests but flag complex metrology tool failures for manual review. Developers configure these rules via workflow orchestration APIs using standard conditional logic—no vendor-controlled decision trees.

The workflow degrades gracefully, falling back to case description analysis when sensor data isn't available. The API response includes a confidence score indicating whether the classification relied on telemetry correlation or text analysis alone—agents see which recommendations are backed by sensor evidence versus symptom patterns. You can configure fallback routing rules that escalate low-confidence cases automatically.

Initial model training typically completes within 48 hours after connecting historical case and telemetry data. The platform requires at least 500 resolved cases per tool family for baseline accuracy. Models retrain continuously as new cases close, adapting to process recipe changes and equipment aging patterns without manual retuning—Python SDKs expose training status APIs so you can monitor model performance over time.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

Connect your telemetry and ticketing systems with Bruviti's API-first platform.

Talk to an Integration Engineer