Fab downtime costs $1M per hour, yet agents waste 8-12 minutes per case searching fragmented systems for recipe parameters and resolution history.

Slow knowledge retrieval in semiconductor customer service stems from fragmented data across multiple systems. AI agents unify technical documentation, case history, and recipe parameters into a single API-accessible knowledge graph, reducing agent lookup time by 65-80%.

Agents toggle between CRM, ERP, knowledge base, and process documentation to answer a single customer question about lithography tool parameters. Each system requires separate logins and search patterns.

Critical information lives in 500-page PDF manuals, scattered email threads, and tribal knowledge. Agents can't find resolution patterns from similar etch tool failures or yield issues.

When a fab reports wafer throughput degradation, agents lack instant access to recipe drift patterns, PM schedules, and consumables usage tied to that specific FOUP batch.

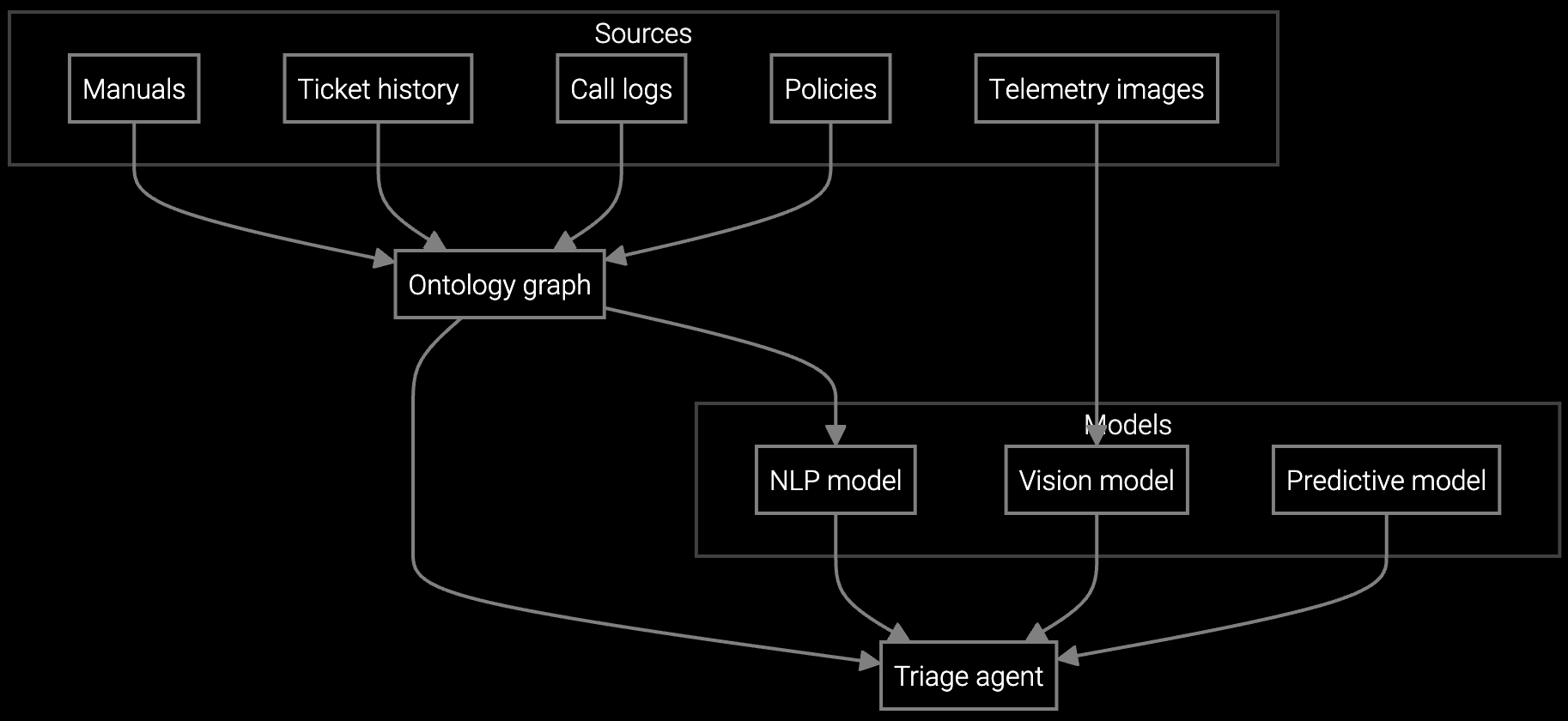

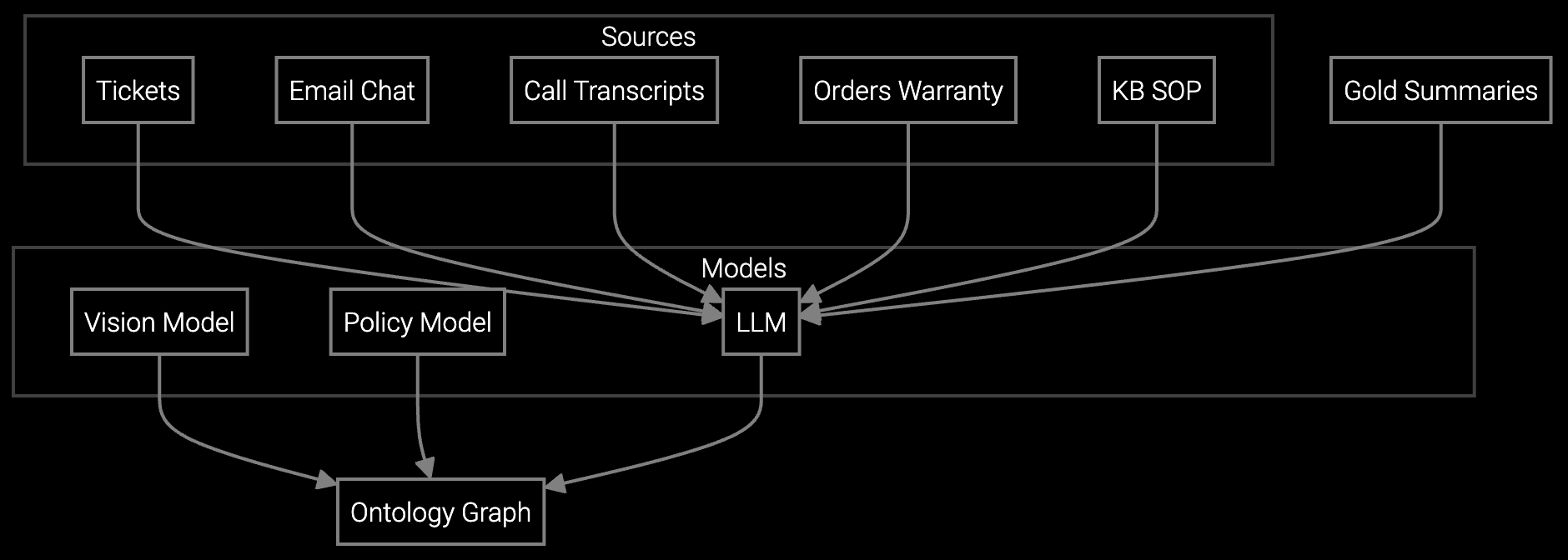

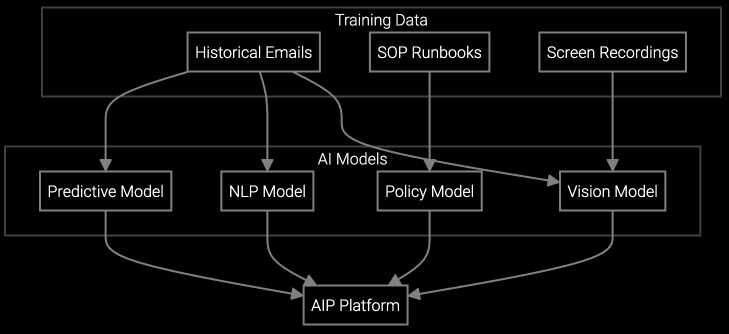

The root cause is architectural: knowledge lives in silos that weren't designed to be queried together. Bruviti's platform ingests telemetry from fab tools, historical case data from CRM systems, and technical documentation from content management systems into a unified knowledge graph. Python SDKs let you query this graph via REST APIs without vendor lock-in.

For semiconductor OEMs, this means agents can retrieve recipe parameters, consumables usage logs, and similar case resolutions in a single API call. You train custom retrieval models on your own case history and documentation, not generic knowledge bases. The platform exposes standard embeddings and vector search endpoints so you control the ranking logic and can A/B test retrieval strategies without replatforming.

Autonomous case classification for semiconductor OEMs analyzes symptom descriptions, correlates fab telemetry, and routes issues to process engineers with equipment context and suggested resolution paths.

Instantly generates structured case summaries from fab call transcripts, email threads, and telemetry logs so agents understand lithography tool history without reading 40+ messages.

AI reads incoming customer emails about etch tool errors, classifies by failure mode, retrieves relevant recipe parameters, and drafts responses using your historical resolution patterns.

Semiconductor customer service operates at extreme precision and cost scales. When a fab customer reports wafer throughput degradation on an EUV lithography system, agents need instant access to recipe drift patterns, PM schedules tied to that specific chamber, and resolution history from similar yield issues across other fab sites. Generic CRM search doesn't cut it.

The platform ingests telemetry from FOUP tracking systems, correlates it with case history, and surfaces recipe-specific context in milliseconds. For deposition tool inquiries, agents retrieve contamination logs, consumables usage, and chamber part replacement schedules without toggling between SAP and tribal knowledge repositories. This matters when downtime costs $1M per hour and every minute of agent search time delays fab recovery.

The platform exposes REST APIs that connect to SAP, Oracle, and custom CRM systems via standard HTTP calls. You don't migrate data or replace existing systems. Python SDKs let you ingest case history, equipment telemetry, and technical documentation into a unified knowledge graph that agents query through your existing CRM interface using embedded widgets or API calls.

Yes. The platform lets you fine-tune embedding models on your own technical content, recipe parameters, and case resolution patterns. You control the training data, model weights, and retrieval logic. This eliminates generic responses and ensures agents get fab-specific answers about lithography recipes, etch parameters, and equipment-specific troubleshooting steps.

The platform uses open standards for data ingestion and retrieval. You access the knowledge graph via REST APIs with standard JSON payloads. Export endpoints let you extract embeddings, case history, and technical documentation in portable formats. If you decide to switch systems, your data and custom models remain accessible through standard Python libraries without proprietary dependencies.

Track average handle time reduction by comparing pre-deployment and post-deployment CRM data for equipment-specific case types. Monitor first contact resolution lift for lithography and etch tool inquiries. Measure agent search time using embedded analytics in the retrieval API. Baseline metrics using existing CRM logs, then track weekly improvements across high-volume case categories like recipe parameter requests and yield issue troubleshooting.

Yes. The platform ingests telemetry streams from MES systems, FOUP tracking, and equipment sensors via MQTT or REST APIs. When a fab customer opens a case about wafer throughput degradation, the system correlates real-time chamber pressure logs, PM schedules, and consumables usage with historical resolution patterns. Agents see equipment-specific context without manual cross-system lookup.

Understanding and optimizing the issue resolution curve.

Part 1: The transformation of IT support with AI.

Part 2: Implementing AI in IT support.

Talk to our integration team about API access, custom model training, and semiconductor-specific deployment patterns.

Schedule Technical Demo