Hyperscale operators demand 99.99% uptime—stockouts cost margins, excess inventory bleeds capital.

Deploy predictive inventory models by integrating BMC telemetry and warranty data into forecasting algorithms, enabling location-specific demand planning that reduces carrying costs while maintaining high fill rates for critical server, storage, and cooling components.

Traditional safety stock formulas for data center parts assume static failure rates, forcing OEMs to hold 30-90 days of inventory across geographically distributed warehouses to avoid SLA penalties during unexpected hardware spikes.

Server generations turn over every 3-5 years, storage architectures evolve from RAID to HCI, and cooling tech shifts from air to liquid. Parts ordered today may be obsolete before they're consumed, creating write-offs that erode aftermarket margins.

When a critical PSU or memory DIMM stocks out at a hyperscale site, next-flight-out shipping costs 10-15x standard freight. A single emergency shipment can erase the profit from an entire quarter's standard service contracts for that location.

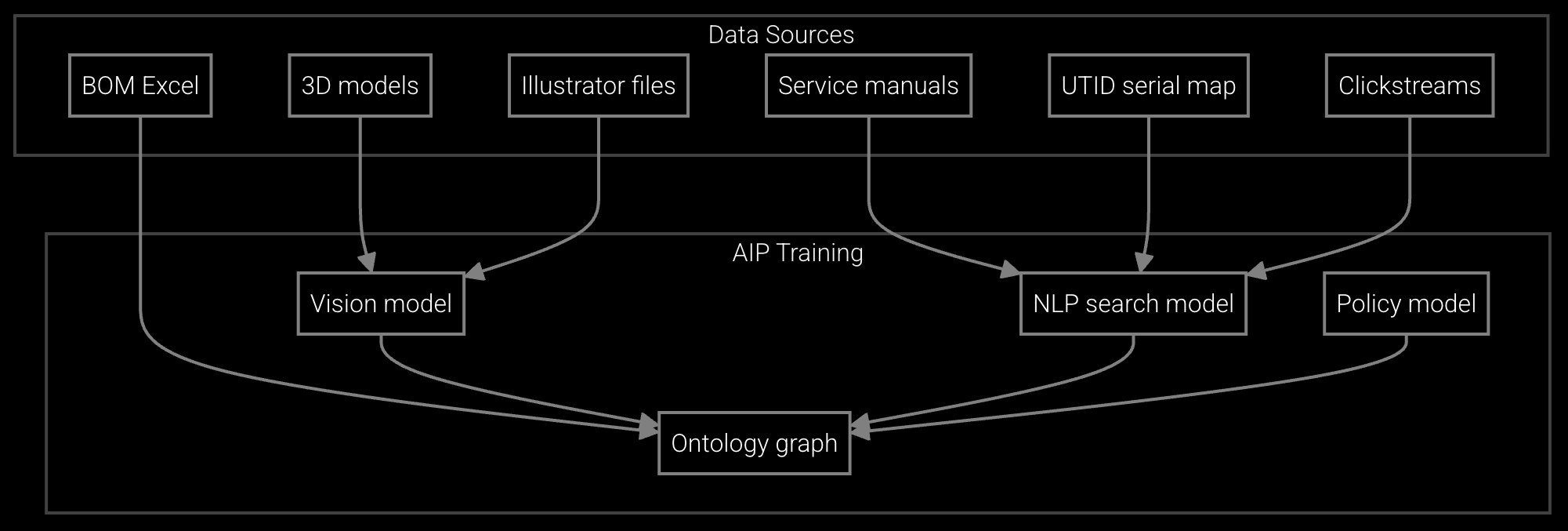

Bruviti's platform integrates with existing ERP and warehouse management systems via REST APIs, ingesting BMC telemetry streams (IPMI sensor data, component health logs), warranty claim histories, and installed base configurations. Machine learning models trained on historical failure patterns generate location-specific demand forecasts updated weekly, automatically triggering replenishment orders when predicted consumption exceeds reorder points.

The system identifies substitute parts when primary SKUs face lead-time delays, matches compatible alternatives across OEM product generations, and prioritizes high-velocity parts for regional distribution centers while consolidating slow-movers in central warehouses. Executives gain dashboard visibility into forecast accuracy, fill rates by location, and carrying cost trends—enabling data-driven decisions on inventory policy without requiring data science expertise on the parts team.

Forecasts server PSU and memory failures by data center location and time window, optimizing stock levels for hyperscale deployments while reducing capital tied up in safety stock.

Projects consumption for cooling system components based on installed base age, PUE trends, and seasonal load patterns across geographically distributed data center portfolios.

Automatically generates and maintains parts catalogs from engineering BOMs and service records, ensuring accurate cross-references across server generations and storage architectures.

Data center OEMs manage parts portfolios spanning thousands of SKUs—from server BMCs and NVMe drives to PDU breakers and CRAC unit compressors. Hyperscale deployments add complexity: a single customer site may house 50,000+ servers across multiple generations, each with unique component configurations and failure profiles.

Predictive models must account for this heterogeneity, learning distinct failure curves for Intel vs. AMD CPUs, recognizing that Gen3 NVMe drives fail differently than Gen4, and understanding that liquid cooling systems have entirely different parts consumption patterns than air-cooled infrastructures. The platform ingests telemetry at scale—processing millions of sensor readings daily from BMC health logs and IPMI data streams—to build statistically significant models even for low-volume, high-criticality parts like UPS battery modules.

Core inputs include BMC/IPMI telemetry (temperature sensors, fan speeds, component health status), warranty claim histories with failure codes, installed base records showing equipment age and configurations, and historical parts consumption from ERP systems. Optional enrichment comes from service ticket data, firmware version tracking, and environmental conditions (ambient temperature, humidity). Models improve accuracy as more historical data is ingested, typically requiring 12-24 months of history for statistically robust predictions.

The system tracks product generation lifecycles and automatically adjusts forecasts as installed base composition shifts. When new server models enter production, transfer learning applies failure patterns from similar prior-generation components while continuously refining predictions as real-world data accumulates. For end-of-life equipment, the platform identifies declining demand curves early, preventing over-ordering and enabling controlled drawdown of obsolete inventory before write-offs become necessary.

Bruviti provides REST API connectors for SAP, Oracle, and Microsoft Dynamics ERP platforms, typically requiring 2-4 weeks of configuration to map part numbers, locations, and transaction types. The platform reads inventory levels, open orders, and consumption history via scheduled API calls (hourly to daily), then writes back recommended replenishment orders as draft purchase requisitions for human approval. No database schema changes are needed—integration runs entirely through standard APIs.

The platform maintains a compatibility graph linking parts across OEM product lines, using engineering specifications (voltage, form factor, connector types) and historical substitution records. When a predicted shortage is detected, the system identifies functionally equivalent alternatives, prioritizes those already in stock at other locations, and calculates total landed cost including inter-warehouse transfers. Substitution suggestions appear in the dashboard with compatibility confidence scores, allowing parts planners to approve alternatives before stockouts occur.

Pilot deployments typically show measurable impact in 90-120 days through reduced emergency shipments and improved fill rates. Full ROI—including inventory reduction, obsolescence avoidance, and carrying cost savings—manifests within 12-18 months as forecasting accuracy stabilizes above 85% and safety stock policies are recalibrated. Data center OEMs commonly achieve 4-7x ROI in year one, with ongoing benefits compounding as models incorporate more operational history and the platform expands across additional product lines and warehouse locations.

SPM systems optimize supply response but miss demand signals outside their inputs. An AI operating layer makes the full picture visible and actionable.

Advanced techniques for accurate parts forecasting.

AI-driven spare parts optimization for field service.

See how Bruviti's predictive platform reduces carrying costs while protecting fill rates and SLA compliance.

Schedule Implementation Review