Manual spreadsheets can't keep pace with hyperscale deployments—and missing configuration data costs you visibility when servers fail.

Connect your BMC/IPMI feeds to an AI platform that auto-populates asset records, tracks configuration changes, and flags firmware drift—eliminating manual spreadsheet updates and giving you real-time visibility into every deployed server, storage array, and cooling unit.

Missing serial numbers, outdated firmware versions, and unknown configuration states leave you blind when equipment fails. You can't route the right part or predict failures without complete asset data.

Firmware updates, BIOS changes, and RAID reconfigurations happen in the field but never make it back to your central database. When actual state diverges from recorded state, troubleshooting takes 3x longer.

Without visibility into contract expiration dates tied to specific assets, service renewals slip through the cracks. Customers churn not because they're unhappy, but because nobody tracked the renewal window.

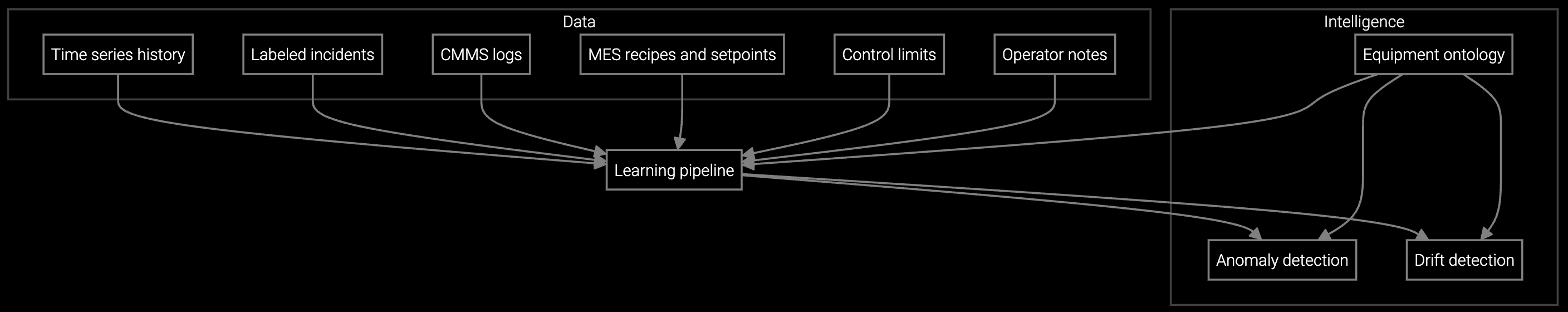

Bruviti connects directly to your BMC and IPMI telemetry streams, parsing hardware sensor data to automatically populate asset records as equipment is deployed. Serial numbers, firmware versions, BIOS configs, and installed memory get recorded without manual entry. When a customer updates RAID configurations or flashes new firmware, the platform detects the change and updates the asset record in real time.

The system flags configuration drift by comparing live telemetry against your baseline standards—alerting you when deployed servers diverge from approved firmware versions or thermal profiles. Contract renewal dates tie directly to asset records, triggering alerts 90 days before expiration so your renewal team can reach out proactively. Instead of searching ten systems to answer "What's deployed at Site X?", you get a single consolidated view showing every server, storage array, and cooling unit with current configuration state.

Parse BMC and IPMI telemetry to detect thermal anomalies, power supply degradation, and drive failures before they cause downtime in hyperscale environments.

Estimate when SSDs, memory modules, and cooling fans will fail based on usage patterns, enabling planned maintenance during scheduled windows instead of emergency outages.

Monitor thousands of data center servers continuously, alerting your team when sensor readings deviate from normal—catching PUE degradation and hot spots before SLA breaches occur.

Data center OEMs ship servers, storage arrays, and cooling systems with BMC and IPMI interfaces already enabled—making telemetry integration straightforward. The platform ingests sensor streams showing CPU temps, fan speeds, power draw, and RAID status as soon as equipment powers on at customer sites. When hyperscale operators deploy 10,000-node clusters in a single month, automated asset tracking eliminates the manual entry bottleneck that used to delay visibility by weeks.

Configuration baselines get defined per product line: approved firmware versions, thermal thresholds, and BIOS settings that match your recommended deployment specs. When a customer flashes beta firmware or misconfigures a RAID array, the drift alert fires immediately—letting your support team intervene before cascading failures occur. Contract records link directly to asset serial numbers, so renewal teams see exactly which equipment is approaching end-of-support and can tailor upgrade offers to actual deployed configurations.

No. The platform auto-discovers assets from BMC and IPMI telemetry as soon as you connect the feeds. For legacy equipment without active telemetry, you can bulk-import serial numbers via CSV, and the system will enrich records as telemetry becomes available. Most deployments achieve 80% asset coverage within 48 hours of feed activation.

You define baseline configurations per product line—approved firmware versions, thermal thresholds, RAID settings. The platform compares live telemetry against these baselines continuously. When a deployed server's firmware version or BIOS setting diverges from the baseline, it triggers a drift alert showing exactly what changed and when.

The platform supports read-only API access and on-premises deployment options for customers with strict network segmentation policies. Alternatively, customers can export telemetry snapshots on a scheduled basis (hourly or daily), which the platform ingests via secure file transfer. Real-time drift detection requires live feeds, but snapshot-based updates still provide visibility far superior to manual tracking.

Yes. Asset records link directly to contract and entitlement data, so you see which equipment is covered, what service level applies, and when coverage expires. The platform triggers renewal alerts 90 days before expiration, giving your team time to reach out proactively. This visibility alone lifts contract attachment rates by 20-30% because renewals no longer slip through the cracks.

Connecting the first BMC/IPMI feed takes about 2 hours—mostly configuring API credentials and firewall rules. Defining configuration baselines for your key product lines adds another 4-6 hours. Most teams go live with automated asset tracking within one business day, and asset coverage reaches 80% within the first week as telemetry streams populate records.

Software stocks lost nearly $1 trillion in value despite strong quarters. AI represents a paradigm shift, not an incremental software improvement.

Function-scoped AI improves local efficiency but workflow-native AI changes cost-to-serve. The P&L impact lives in the workflow itself.

Five key shifts from deploying nearly 100 enterprise AI workflow solutions and the GTM changes required to win in 2026.

See how Bruviti connects to your telemetry feeds and eliminates manual data entry in under a week.

Schedule Demo