Fab downtime costs $1M per hour, making parts availability a strategic imperative requiring careful platform decisions.

Build custom parts models for full control but 18+ month timelines, or deploy vendor platforms in 90 days with API extensibility. Hybrid approaches balance customization with speed for semiconductor fab parts management.

Custom forecasting models require extensive training data, model tuning, and integration work. Semiconductor fabs can't afford extended pilot phases when chamber kit stockouts halt production.

Closed platforms trap customization inside proprietary environments. When business logic lives in vendor-controlled workflows, data extraction and model portability become expensive migrations.

Models drift as equipment mix changes and new tools enter production. In-house solutions require dedicated teams to retrain models, update integrations, and manage infrastructure.

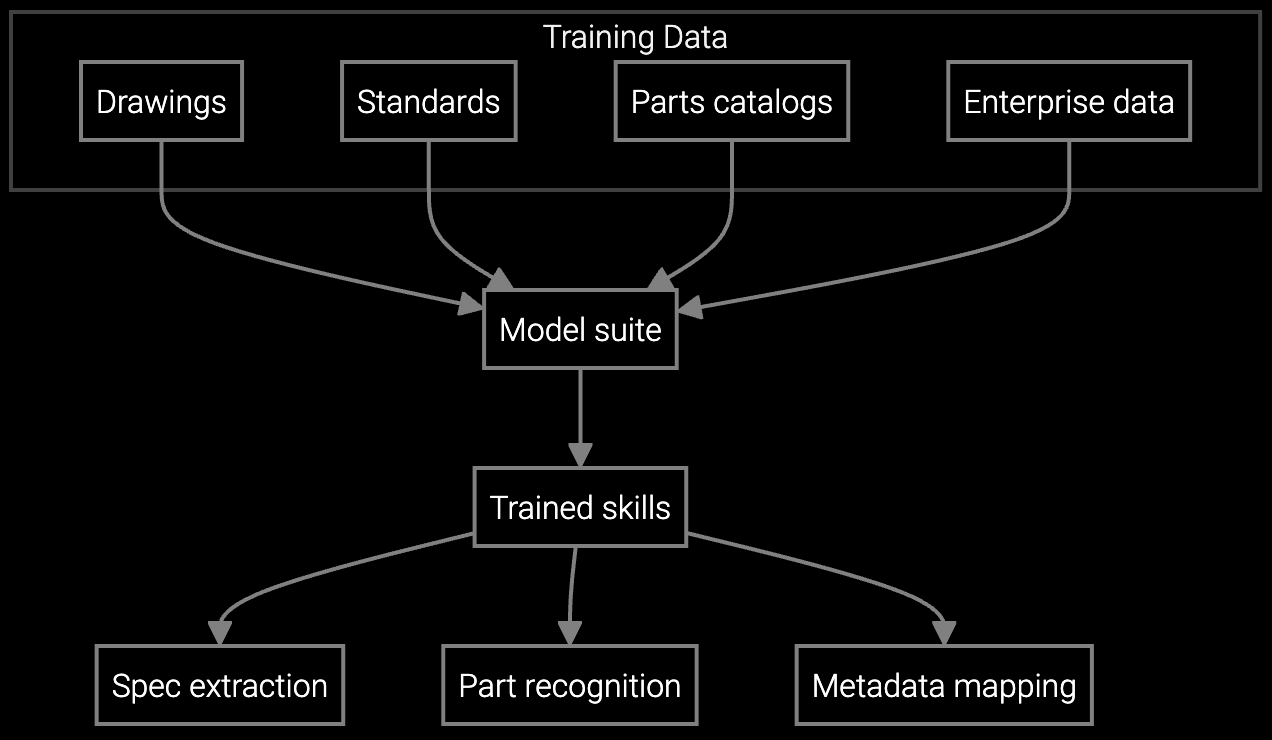

Bruviti's headless architecture separates forecasting intelligence from implementation flexibility. Python SDKs expose demand prediction, substitute matching, and inventory optimization as composable services. Your team owns the integration layer, business logic lives in your codebase, and data never leaves your control unless explicitly pushed to shared models.

The platform ingests telemetry from fab MES systems, processes tool usage patterns and chamber kit consumption rates, then surfaces predictions through REST APIs. When forecast accuracy degrades, retrain with your data using standard ML toolchains. Deploy models to your infrastructure or use managed hosting. Swap vendors without rewriting integration code because your stack calls standard endpoints, not proprietary workflows.

Projects chamber kit consumption based on tool utilization patterns, wafer throughput forecasts, and preventive maintenance schedules across fab equipment.

Optimizes stock levels by warehouse location using historical demand variability, supplier lead times, and critical spares classification for etch and deposition tools.

Reads technical drawings and assembly schematics to extract part numbers, accelerating quoting when process engineers request custom chamber configurations.

Semiconductor fabs carry $50M+ in parts inventory across chamber kits, consumables, and critical spares for lithography and etch tools. A single plasma chamber rebuild kit can cost $200K, making stockouts catastrophic but excess inventory a balance sheet burden. Parts strategy must account for both critical spares with unpredictable failure patterns and high-volume consumables with seasonal demand.

API-first platforms integrate with SAP or Oracle ERP systems already managing procurement workflows. Forecasting models ingest real-time telemetry from SECS/GEM interfaces on fab tools, correlating equipment performance with historical parts consumption. When chamber recipe changes or new process nodes enter production, retrain models using your fab's actual usage data rather than waiting for vendor model updates.

Full control over integration logic, data transformation, and business rules. You call forecasting APIs from your codebase, so demand prediction becomes a service rather than a black box. Swap model providers, adjust thresholds, or implement custom inventory policies without vendor dependencies.

Bruviti uses standard ML formats and open APIs. Models train on data you control, deploy to infrastructure you choose, and integrate through REST endpoints documented in OpenAPI specs. Export model weights, retrain with alternative frameworks, or migrate to different hosting without rewriting application code.

Deploy vendor forecasting models in 90 days to achieve immediate stockout reduction and fill rate improvements. Run parallel custom model development for specialized use cases like recipe-specific consumable forecasting. Transition to hybrid architecture over 12-18 months as your team builds ML expertise and infrastructure.

Fab parts management demands high-value SKU handling, integration with SECS/GEM tool interfaces, and support for complex bill-of-materials structures. Platforms must handle both critical spares with lumpy demand and consumables with predictable patterns. Look for semiconductor industry expertise in telemetry interpretation and recipe-aware forecasting.

Minimal on-premises requirements beyond standard REST API connectivity. Host models in your cloud environment or use vendor-managed infrastructure. Most integrations require only outbound HTTPS access from ERP and MES systems. Data sovereignty options available for customers requiring all processing within controlled networks.

SPM systems optimize supply response but miss demand signals outside their inputs. An AI operating layer makes the full picture visible and actionable.

Advanced techniques for accurate parts forecasting.

AI-driven spare parts optimization for field service.

See how Bruviti's headless platform integrates with semiconductor fab systems without vendor lock-in.

Schedule Technical Review