Manual forecasting and replenishment tie up millions in excess inventory while critical parts still go missing when equipment fails.

Automate demand forecasting, substitute matching, and replenishment workflows to reduce carrying costs while maintaining parts availability. AI orchestrates end-to-end inventory decisions, minimizing stockouts and excess capital tied up in spare parts.

Safety stock formulas built for predictable demand fail with long-lifecycle industrial equipment. Parts for decades-old machinery accumulate in warehouses while newer models face shortages. Finance sees millions tied up in slow-moving inventory.

Missing a critical part means emergency freight, delayed repairs, and customer downtime charges. Manual replenishment workflows can't predict failure spikes across distributed equipment populations. Service teams scramble while contracts bleed margin.

Obsolete parts force manual searches through cross-reference tables and engineering drawings. What should take minutes consumes hours as planners contact suppliers and validate compatibility. Customers wait while inventory sits unused.

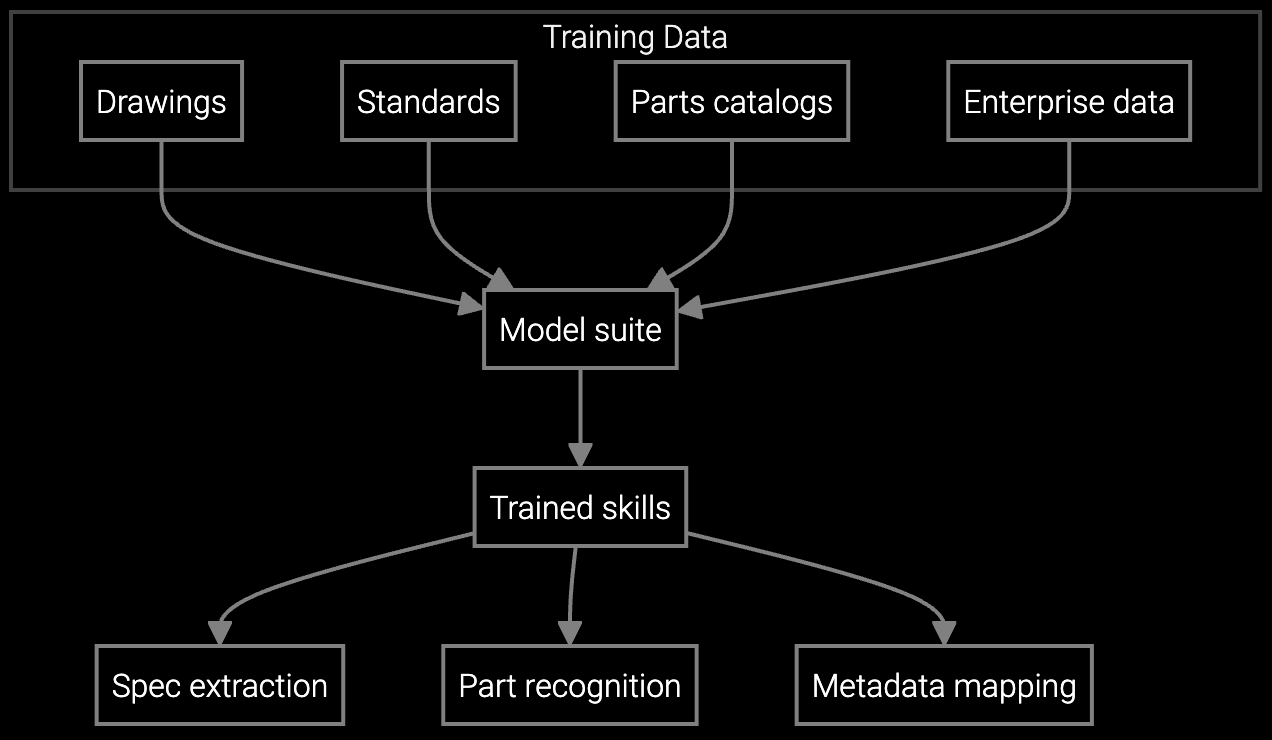

Bruviti automates the entire inventory decision chain from demand signal to replenishment order. The platform ingests failure patterns, installed base telemetry, and service history to forecast parts consumption by location and time window. When equipment data indicates an emerging failure mode, the system automatically adjusts safety stock before manual planners see the trend.

For obsolete parts, AI matches specifications against current inventory and supplier catalogs in seconds. The workflow orchestrates approval routing, generates purchase orders, and updates ERP systems without manual intervention. Service teams see real-time availability while finance tracks carrying cost reductions and eliminated emergency freight charges.

Predicts consumption patterns for industrial equipment based on installed base age, run hours, and seasonal usage trends.

Optimizes stock levels across warehouse locations using failure probability and lead time analytics.

Extracts part numbers from legacy technical drawings and schematics to accelerate obsolete parts replacement.

Industrial equipment manufacturers face 10-30 year service obligations across globally distributed installations. CNC machines, turbines, and automation systems accumulate parts demand variability as equipment ages and usage patterns shift. Traditional reorder point formulas fail when a single pump model spans three decades of manufacturing revisions.

AI-driven workflows learn from installed base telemetry—vibration signatures, run hours, operating conditions—to predict which parts will fail before manual planners see the pattern. The platform routes replenishment decisions through existing approval hierarchies while maintaining visibility into slow-moving inventory by equipment vintage and geography.

Traditional reorder points use historical averages and assume steady demand. AI models ingest installed base telemetry, failure mode patterns, and seasonal usage to predict consumption by location and time window. When vibration data signals an emerging bearing failure across a turbine population, the system adjusts safety stock before the spike hits. This reduces both stockouts and excess inventory simultaneously.

Industrial OEMs typically see 18-24% carrying cost reduction from optimized safety stock and faster inventory turns. Emergency freight elimination saves $1.5-3M annually depending on installed base size. Fill rate improvements from 78% to 92% protect service margins and reduce SLA penalty exposure. Total first-year impact ranges from $2-5M for manufacturers with $100M+ aftermarket revenue.

Bruviti's AI reads engineering specifications, cross-reference tables, and supplier catalogs to identify compatible substitutes in seconds. For a discontinued bearing, the system matches dimensional tolerances, load ratings, and mounting configurations against current inventory and supplier databases. This replaces 4-hour manual searches with automated recommendations that route through existing approval workflows.

Yes. The platform connects to SAP, Oracle, and other ERP systems via standard APIs to read inventory levels and write replenishment orders. Real-time availability data flows to service portals and case management systems. The AI layer sits between demand signals and ERP execution, automating decisions while maintaining your existing approval hierarchies and business rules.

Track fill rate improvement against service margin protection—each percentage point gain in availability reduces stockout-related penalties and emergency freight. Monitor inventory turns by product line to quantify capital freed up for reallocation. Measure forecast accuracy improvement over baseline methods to validate demand prediction gains. Most industrial OEMs see payback in 8-14 months from combined carrying cost reduction and penalty avoidance.

SPM systems optimize supply response but miss demand signals outside their inputs. An AI operating layer makes the full picture visible and actionable.

Advanced techniques for accurate parts forecasting.

AI-driven spare parts optimization for field service.

See how Bruviti reduces carrying costs while eliminating stockouts across your installed base.

Schedule Demo