Distributed facilities and unpredictable server failures make manual inventory planning a margin killer.

Data center OEMs automate parts workflows by connecting inventory systems to demand forecasting models that predict component failures across distributed facilities, triggering replenishment before stockouts delay customer SLAs while reducing carrying costs through optimized stocking levels.

Hyperscale customers operate across dozens of facilities. When a critical power supply or memory module isn't available at the closest warehouse, emergency shipments erode service margins while the customer's SLA clock ticks.

Conservative stocking policies hedge against stockouts but create warehouses full of slow-moving PDUs, cooling modules, and obsolete server generations that never get deployed. The carrying cost drags down operating margins quarter after quarter.

Data center equipment refresh cycles accelerate faster than parts age out. Last generation's RAID controllers and legacy cooling sensors accumulate in inventory until they're written off, directly hitting the P&L with no revenue offset.

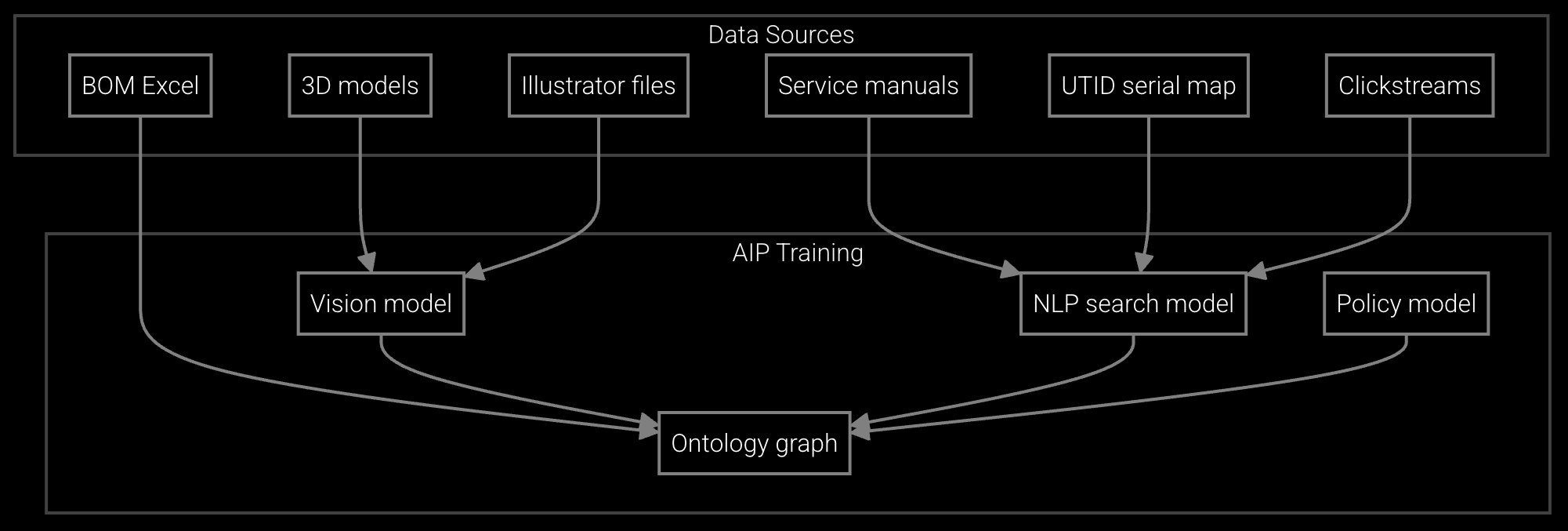

Bruviti's platform connects to your SAP or Oracle inventory system and ingests BMC telemetry streams from deployed servers, storage arrays, and cooling infrastructure. Machine learning models analyze failure patterns by component type, installed base age, and facility load to predict parts demand by location and time window. The system automatically triggers purchase orders and inter-facility transfers before stockouts occur.

The workflow replaces manual spreadsheet planning with continuous optimization. When telemetry signals rising SMART errors on a specific hard drive model deployed at hyperscale customer sites, the system calculates expected failure volumes across all facilities, compares current stock levels, and initiates replenishment to the warehouses closest to likely demand. Planners review recommendations rather than building forecasts from scratch, reallocating time to supplier negotiations and substitution strategies.

Projects server component consumption based on installed base age, BMC telemetry patterns, and facility utilization trends across hyperscale deployments.

Forecasts power supply and cooling module demand by data center location and time window, optimizing stock levels while reducing emergency shipment costs.

Automatically generates and maintains parts catalogs from server engineering data and field service records, ensuring accuracy as product lines evolve.

Data center OEMs face inventory planning complexity that manual methods can't solve. Hyperscale customers operate hundreds of facilities with millions of servers, each containing dozens of serviceable components. A single PDU model might be deployed across 50 sites with vastly different failure rates driven by local power grid quality and cooling efficiency (PUE variability). Traditional demand planning treats all locations identically, creating systematic over-stocking in stable sites and chronic stockouts in high-stress environments.

The platform ingests IPMI telemetry from deployed equipment to identify failure pattern variance by facility. A power supply running at 85% capacity in a hot aisle with poor PUE has a measurably different failure curve than the same unit in an optimized cold aisle. Automated forecasting incorporates these micro-environmental factors, allocating inventory where physics predicts it will be needed rather than spreading it evenly across all warehouses.

The platform connects via standard ERP APIs to read current stock levels, open purchase orders, and historical consumption data. It writes back demand forecasts and recommended replenishment quantities that your procurement team reviews before converting to POs. The integration preserves your existing approval workflows while automating the forecasting calculations that currently happen in spreadsheets.

The strongest signal comes from BMC telemetry (IPMI data) showing component health metrics like power supply voltage variance, memory error correction rates, and thermal sensor readings. Combining this real-time equipment health data with installed base age and facility environmental factors (PUE, local power grid quality) produces forecasts 40-60% more accurate than historical consumption averages alone.

The system applies safety stock buffers calculated from forecast confidence intervals and lead time variability. For critical components where stockouts trigger SLA penalties, you configure higher service level targets that maintain larger buffers. The automation optimizes inventory levels within your risk tolerance rather than eliminating safety stock entirely. Planners retain override authority for major demand events like new customer deployments.

Most data center OEMs see measurable carrying cost reduction within the first quarter as the system identifies slow-moving stock and prevents over-ordering. Emergency shipment cost savings appear within 60-90 days as predictive replenishment prevents stockouts. Full ROI typically lands in 6-9 months, with payback accelerating as forecast accuracy improves with additional training data.

The system tracks installed base composition by product generation and projects remaining service demand as older equipment ages out. When a server model approaches end-of-service life, the forecasting algorithm tapers replenishment orders to draw down inventory at the same rate deployments decline. This prevents accumulation of obsolete stock while maintaining availability for legacy support obligations. You configure phase-out timelines based on your service contract terms and customer refresh schedules.

SPM systems optimize supply response but miss demand signals outside their inputs. An AI operating layer makes the full picture visible and actionable.

Advanced techniques for accurate parts forecasting.

AI-driven spare parts optimization for field service.

See how Bruviti automates demand forecasting and replenishment for data center equipment OEMs.

Schedule Demo